Abstract

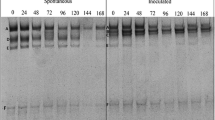

An experimental design considering thermal treatment of must, yeast strain, prickly pear variety and degree of ripeness was chosen to evaluate the fermentation behavior and generation of volatile compounds, during the elaboration of a distilled beverage from prickly pear. Four Mexican prickly pear varieties were characterized physically and two of them were selected for fermentation studies. The thermal treatment of the must showed the highest statistical influence on fermentation behavior and production of volatile compounds, followed by prickly pear variety, then yeast strain and finally the degree of ripeness was the least statistically significant factor. The growth rate increased when the thermal treatment was applied whereas the ethanol production rate and alcoholic efficiency were unaffected. The results also suggested that thermal treatment was effective for inhibition of microbial contamination. As regards volatile compounds production, acetic acid and methanol decreased while other volatiles increased when the thermal treatment was applied. Despite the influence of thermal treatment, prickly pear variety strongly influences the volatile profile of fermented musts.

Similar content being viewed by others

References

Barbera G, Carimi F, Inglese P, Panno M (1992) Physical, morphological and chemical changes during fruit development and ripening in three cultivars of prickly pear, Opuntia ficus-indica (L.) Miller. J Hortic Sci 67(3):307–312

Barbera G, Inglese P, La Mantia T (1994) Seed content and fruit characterization in cactus pear (Opuntia ficus-indica Mill.). Sci Hortic 58:161–165

Berthels NJ, Cordero-Otero RR, Bauer FF, Thevelin JM, Pretorious IS (2004) Discrepancy in glucose and fructose utilization during fermentation by Saccharomyces cerevisiae wine yeast strains. FEMS Yeast Res 4:683–689

Boehringer P, Jacob L (1964) The determination of alcohol using chromic acid. Zeitschr Flussinges Abst 31:233–236

Boulanger R, Crouzet J (2001) Changes of volatile compounds during heating of bacuri pulp. J Agric Food Chem 49:5911–5915

Bravo-Hollis H (1978) El Cultivo de la tuna. In: UNAM (ed) Las cactaceas de México vol 1. Universidad Nacional Autánoma de México, Mexico city, Mexico, pp 132–161

Bustos OE (1981) Alcoholic beverage from Chilean Opuntia ficus-indica. Am J Enol Vitic 32(3):228–229

Derrick S, Large P (1993) Activities of the enzymes of the Ehrlich pathway and formation of branched-chain alcohols in Saccharomyces cerevisiae and Candida utilis grown in continuous culture on valine or ammonium as sole nitrogen source. J Gen Microbiol 139(11):2783–2792

Dickinson JR, Lanterman M, Danner DJ, Pearson BM, Sanz P, Harrison S, Hewlins JE (1997) A 13c nuclear investigation of the metamolism of leucina to isoamyl alcohol in Saccharomyces cerevisiae. J Biol Chem 272(43):26871–26878

El Kossori RL, Villanume C, El Boustani E, Sauvaire Y, Menean L (1998) Composition of pulp, skin and seeds of prickly pears fruits (Opuntia ficus indica). Plant Foods Hum Nutr 52:263–270

Espinoza AI, Barrocal R, Jara M, Zarabia PC (1978) Quelques propietés et études preliminaires de conservation des fruits et du jus de figue de barbarie (Opuntia ficus-indica). Fruits 28:285–289

Felker P, Singh G, Pareek OP (1997) The opportunities for development of cactus (Opuntia spp.) in arid and semi-arid regions. Ann Arid Zone 36(3):267–268

Fiore C, Arrizon J, Gschaedler A, Flores J, Romano P (2005) Comparison between wine and agave yeast strains for traits of technological interest. World J Microbiol Biotechnol 21(6–7):1141–1147

Flath RA, Takahashi JM (1978) Volatile constituents of prickly pear (Opuntia ficus indica Mill., de Castilla variety). J Agric Food Chem 26(4):835–837

Galati EM, Mondello MR, Giuffrida D, Dugo G, Miceli N Pergolizzi S, Taviano MF (2003) Chemical characterization and biological effects of Sicilian Opuntia ficus-indica (L) mill. fruit juice: antioxidant and antiulcerogenic activity. J Agric Food Chem 51:4903–4908

Gueguen Y, Chemardin P, Janbon G, Arnaud A, Galzy P (1996) A very efficient β-glucosidase catalyst for the hydrolysis of flavor precursors of wines and fruit juices. J Agric Food Chem 44:2336–2340

Gurrieri S, Miceli L, Lanza CM, Tomaselli F, Bonomo RP, Rizzarelli E (2000) Chemical characterization of Sicilian prickly pear (Opuntia ficus indica) and perspectives for the storage of its juice. J Agric Food Chem 48:5424–5431

Koulibaly A, Sakho M, Crouzet J (1992) Variability of free and bound volatile terpenic compounds in mango. Lebensm Wiss Technol 25:374–379

Kuti JO (1992) Growth and compositional changes during the development of prickly pear fruit. J Hortic Sci 67(6):861–868

Kuti JO, Galloway CM (1994) Sugar composition and invertase activity in prickly pear fruit. J Food Sci 59:387–388

Ledauphin J, Guichard H, Saint-Clair J-F, Bernard P, Barillier D (2003) Chemical and sensorial aroma characterization of freshly distilled calvados. 2. Identification of volatile compounds and key odorants. J Agric Food Chem 51:433–442

Lilly M, Lambrechts MG, Pretorius IS (2000) Effect of increased yeast alcohol acetyltransferase activity on flavor profiles of wine and distillates. Appl Environ Microbiol 66(2):744–753

Maarse H (1992) Wine, distilled beverages. In: Maarse H (ed) Volatile compounds in foods and beverages. Arcel Dekker Inc., Ámsterdam, pp 483–580

Miller GL (1959) Use of dinitrosalicylic acid reagent for determination of reducing sugar. Anal chem 31(3):426–428

NOM-006-SCFI (Secretaría de Comercio y Fomento Industrial) (1994) Norma Oficial Mexicana

Pimienta-Barrios E, Mauricio-Leguízamo R (1989) Variación en componentes del fruto maduro entre formas de nopal (Opuntia spp.) tunero. Fitotec Mex 12:183–196

Pronk JT, Steensma HY, van Dijken JP (1996) Piruvate metabolism in Saccharomyces cerevisiae. Yeast 12:1607–1633

Retamal N, Durán JM, Fernández J (1987) Ethanol production by fermentation of fruits and cladodes of prickly pear cactus [Opuntia ficus-indica (L) Miller]. J Sci Food Agric 40:213–218

Rodríguez-Madrera R, Blanco-Gomis D, Mangas-Alonso JJ (2003) Influence of distillation system, oak wood type, and aging time on volatile compounds of cider brandy. J Agric Food Chem 51:5709–5714

Romano P, Fiore C, Paraggio M, Caruso A, Capece A (2003) Function of yeasts species and strains in wine flavour. Int J Food Microbiol 86:169–180

Sawaya WN, Khalh JK, Al-Muhammed HM (1983) Nutritive value of prickly pear seed, Opuntia ficus-indica. Plant Food Hum Nutr 33:91–97

Sepúlveda E, Sáenz C (1990) Nota, Características químicas y físicas de pulpa de tuna (Opuntia Picus-indica). Rev Agroquim Tecnol 30(4):551–555

Silva ML, Malcata FX (1998) Relationships between storage conditions of grape pomace and volatile composition of spirits obtained therefrom. Am J Enol Vitic 49(1):56–64

Schreier P, Drawert M, Schmid M (1978) Changes in the composition of neutral volatile components during the production of Apple Brandy. J Sci Food Agric 29:728–736

Stark D, Münch T, Sonnleitner B, Marison IW, von Sockar U (2002) Extractive bioconversion of 2-phenylethanol from l-phenylalanine by Saccharomyces cerevisiae. Biotechnol Prog 18:514–523

William AA, Tucknott OG (1971) Volatile constituents of fermented cider. I. Draught dry cruder blend. J Sci Food Agric 22:264–269

Acknowledgments

This work was supported by “Fundación Produce San Luis Potosí” (México) grant.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Arrizon, J., Calderón, C. & Sandoval, G. Effect of different fermentation conditions on the kinetic parameters and production of volatile compounds during the elaboration of a prickly pear distilled beverage. J Ind Microbiol Biotechnol 33, 921–928 (2006). https://doi.org/10.1007/s10295-006-0153-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10295-006-0153-9