Abstract

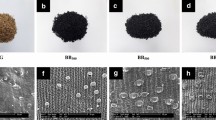

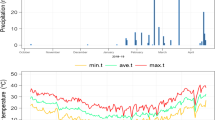

The study explored the use of brewery spent grain (BSG) for creating a biodegradable pot that releases nutrients. Sixteen different composite formulations were prepared using clay as a filler, polyvinyl acetate (PVAc) as a binder, and glycerol as a plasticizer. The composition ratio was critical in achieving a homogeneous matrix and pot formability. The T10 and T14 pot formulations, with a clay:PVAc:glycerol ratio of 100:50:25, performed best and were chosen for soil burial testing. The impact of BSG content on biodegradability and mineralization was investigated. T10 showed twice the degradation of T14 after 45 days in soil due to higher BSG content, resulting in greater weight loss. Soil pH and electrical conductivity remained constant, indicating minimized soil acidity. Although a solid matrix hindered water penetration and reduced soil microflora, cracking and erosion were observed. Organic matter and total nitrogen in adjacent soil significantly increased from Day0 to Day45 for both T10 and T14, indicating nutrient release during biodegradation. The study concluded that BSG could be used to produce biodegradable pots with nutrient release potential, providing a sustainable alternative to conventional plastic seeding bag or pot.

Similar content being viewed by others

Data availability

Data sharing not applicable to this article as no datasets were generated or analyzed during the current study.

References

Fagan ME, Reid JL, Holland MB, Drew JG, Zahawi RA (2020) How feasible are global forest restoration commitments? Conserv Lett 13:e12700. https://doi.org/10.1111/conl.12700

Stanturf JA, Kleine M, Mansourian S, Parrotta J, Madsen P, Kant P, Burns J, Bolte A (2019) Implementing forest landscape restoration under the Bonn challenge: a systematic approach. Ann For Sci 76:1–21. https://doi.org/10.1007/s13595-019-0833-z

Matemilola S, Fadeyi O, Sijuade T (2020) Paris agreement. In: Idowu SO (ed) Encyclopedia of sustainable management. Springer Place Publishe, New York, pp 1–5

Liew KC, Khor LK (2015) Effect of different ratios of bioplastic to newspaper pulp fibres on the weight loss of bioplastic pot. J King Saud Univ Eng Sci 27:137–141. https://doi.org/10.1016/j.jksues.2013.08.001

Tomadoni B, Merino D, Alvarez VA (2020) Biodegradable materials for planting pots. In: Amir Al-Ahmed, Inamuddin (ed) Advanced applications of bio-degradable green composites. Materials Research Forum LLC, Pennsylvania, pp 85–103

Saha S, Hariprasad P (2022) Paddy straw-based biodegradable horticultural pots: An integrated greener approach to reduce plastic waste, valorize paddy straw and improve plant health. J Clean Prod 337:130588. https://doi.org/10.1016/j.jclepro.2022.130588

Mussatto SI, Roberto IC (2006) Chemical characterization and liberation of pentose sugars from brewer’s spent grain. J Chem Technol Biotechnol 81:268–274. https://doi.org/10.1002/jctb.1374

Garrett R, Bellmer D, McGlynn W, Rayas-Duarte P (2021) Development of new chip products from brewer’s spent grain. J Food Qual 2021:5521746. https://doi.org/10.1155/2021/5521746

Lynch KM, Steffen EJ, Arendt EK (2016) Brewers’ spent grain: a review with an emphasis on food and health. J Inst Brew 122:553–568. https://doi.org/10.1002/jib.363

Chin YL, Chai KF, Chen WN (2022) Upcycling of brewers’ spent grains via solid-state fermentation for the production of protein hydrolysates with antioxidant and techno-functional properties. Food Chem X 13:100184. https://doi.org/10.1016/j.fochx.2021.100184

Nsoanya LN, Nweke IA (2015) Effect of integrated use of spent grain and NPK (20:10:10) fertilizer on soil chemical properties and maize (Zea Mays L) growth. Int J Res Agric For 2:14–19

Aboukila EF, Nassar IN, Rashad M, Hafez M, Norton JB (2018) Reclamation of calcareous soil and improvement of squash growth using brewers’ spent grain and compost. J Saudi Soc Agric Sci 17:390–397. https://doi.org/10.1016/j.jssas.2016.09.005

Yoo JH, Luyima D, Lee JH, Park SY, Yang JW, An JY, Yun YU, Oh TK (2021) Effects of brewer’s spent grain biochar on the growth and quality of leaf lettuce (Lactuca sativa L. var. crispa.). Appl Biol Chem 64:1–10. https://doi.org/10.1186/s13765-020-00577-z

Manolikaki I, Diamadopoulos E (2020) Agronomic potential of biochar prepared from brewery byproducts. J Environ Manage 255:109856. https://doi.org/10.1016/j.jenvman.2019.109856

Nathan MV, Gelderman R (2015) Recommended chemical soil test procedures for the North Central Region (No. 221). Missouri Agricultural Experiment Station, University of Missouri, Columbia

Sintim HY, Bandopadhyay S, English ME, Bary AI, DeBruyn JM, Schaeffer SM, Miles CA, Reganold JP, Flury M (2019) Impacts of biodegradable plastic mulches on soil health. Agric Ecosyst Environ 273:36–49. https://doi.org/10.1016/j.agee.2018.12.002

Lee KC, Her JH, Kwon SK (2008) Red clay composites reinforced with polymeric binders. Constr Build Mater 22:2292–2298. https://doi.org/10.1016/j.conbuildmat.2007.10.008

Kale G, Auras R, Singh SP, Narayan R (2007) Biodegradability of polylactide bottles in real and simulated composting conditions. Polym Test 26:1049–1061. https://doi.org/10.1016/j.polymertesting.2007.07.006

Mohee R, Unmar G (2007) Determining biodegradability of plastic materials under controlled and natural composting environments. Waste Manage 27:1486–1493. https://doi.org/10.1016/j.wasman.2006.07.023

Springob G, Kirchmann H (2003) Bulk soil C to N ratio as a simple measure of net N mineralization from stabilized soil organic matter in sandy arable soils. Soil Biol Biochem 35:629–632. https://doi.org/10.1016/S0038-0717(03)00052-X

Påhlsson A-MB (1989) Toxicity of heavy metals (Zn, Cu, Cd, Pb) to vascular plants. Water Air Soil Pollut 47:287–319. https://doi.org/10.1007/BF00279329

Ostos JC, López-Garrido R, Murillo J, López R (2008) Substitution of peat for municipal solid waste-and sewage sludge-based composts in nursery growing media: Effects on growth and nutrition of the native shrub Pistacia lentiscus L. Bioresour Technol 99:1793–1800. https://doi.org/10.1016/j.biortech.2007.03.033

Bünemann EK, Bongiorno G, Bai Z, Creamer RE, De Deyn G, De Goede R, Fleskens L, Geissen V, Kuyper TW, Mäder P (2018) Soil quality–A critical review. Soil Biol Biochem 120:105–125. https://doi.org/10.1016/j.soilbio.2018.01.030

Malicki M, Walczak R (1999) Evaluating soil salinity status from bulk electrical conductivity and permittivity. Eur J Soil Sci 50:505–514. https://doi.org/10.1046/j.1365-2389.1999.00245.x

Aragüés R, Urdanoz V, Çetin M, Kirda C, Daghari H, Ltifi W, Lahlou M, Douaik A (2011) Soil salinity related to physical soil characteristics and irrigation management in four Mediterranean irrigation districts. Agric Water Manage 98:959–966. https://doi.org/10.1016/j.agwat.2011.01.004

Brust GE (2019) Management strategies for organic vegetable fertility. In: Biswas D, Micallef SA (eds) Safety and practice for organic food. Academic Press, MA, pp 193–212

Pramanik P, Ghosh G, Ghosal P, Banik P (2007) Changes in organic C, N, P and K and enzyme activities in vermicompost of biodegradable organic wastes under liming and microbial inoculants. Bioresour Technol 98:2485–2494. https://doi.org/10.1016/j.biortech.2006.09.017

Assandri D, Pampuro N, Zara G, Cavallo E, Budroni M (2020) Suitability of composting process for the disposal and valorization of brewer’s spent grain. Agriculture 11:2. https://doi.org/10.3390/agriculture11010002

Theuer M (2005) Plant pot that fertilizes when it biodegrades. US20050188612A1: United States

Manafi-Dastjerdi M, Ebrahimi-Nik M, Rohani A, Lawson S (2022) Production of biodegradable pots from cattle manure and wood waste: effects of natural binders on mechanical performances and biodegradability. Environ Sci Pollut Res Int 29:20265–20278. https://doi.org/10.1007/s11356-021-17235-6

Commission E (1986) Council Directive 86/278/EEC of 12 June 1986 on the protection of the environment, and in particular of the soil, when sewage sludge is used in agriculture. Off J 181:6–12

Office of the Federal Register (2023) 40CFR503.13 Pollutant limits. National archives and records administration Website https://www.ecfr.gov/current/title-40/section-503.13 Accessed 23 Aug 2023

Basiak E, Lenart A, Debeaufort F (2018) How glycerol and water contents affect the structural and functional properties of starch-based edible films. Polymers 10:412. https://doi.org/10.3390/polym10040412

Mbagwu J, Ekwealor G (1990) Agronomic potential of brewers’ spent grains. Biol Wastes 34:335–347. https://doi.org/10.1016/0269-7483(90)90034-P

Yamauchi M, Masuda S, Kihara M (2006) Recycled pots using sweet potato distillation lees. Resour Conserv Recycl 47:183–194. https://doi.org/10.1016/j.resconrec.2005.10.008

Kijchavengkul T, Auras R, Rubino M, Ngouajio M, Fernandez RT (2006) Development of an automatic laboratory-scale respirometric system to measure polymer biodegradability. Polym Test 25:1006–1016. https://doi.org/10.1016/j.polymertesting.2006.06.008

Guarda EC, Oliveira AC, Antunes S, Freitas F, Castro PM, Duque AF, Reis MA (2021) A two-stage process for conversion of brewer’s spent grain into volatile fatty acids through acidogenic fermentation. Appl Sci 11:3222. https://doi.org/10.3390/app11073222

Coma ME, Peltzer MA, Delgado JF, Salvay AG (2019) Water kefir grains as an innovative source of materials: study of plasticiser content on film properties. Eur Polym J 120:109234. https://doi.org/10.1016/j.eurpolymj.2019.109234

Schettini E, Santagata G, Malinconico M, Immirzi B, Mugnozza GS, Vox G (2013) Recycled wastes of tomato and hemp fibres for biodegradable pots: Physico-chemical characterization and field performance. Resour Conserv Recycl 70:9–19. https://doi.org/10.1016/j.resconrec.2012.11.002

Shrestha A, Van-Eerten Jansen MC, Acharya B (2020) Biodegradation of bioplastic using anaerobic digestion at retention time as per industrial biogas plant and international norms. Sustainability 12:4231. https://doi.org/10.3390/su12104231

Funabashi M, Ninomiya F, Kunioka M (2009) Biodegradability evaluation of polymers by ISO 14855–2. Int J Mol Sci 10:3635–3654. https://doi.org/10.3390/ijms10083635

Anikwe MA, Nwobodo KC (2002) Long term effect of municipal waste disposal on soil properties and productivity of sites used for urban agriculture in Abakaliki, Nigeria. Bioresour Technol 83:241–250. https://doi.org/10.1016/s0960-8524(01)00154-7

Ahamefula OE (2016) Improving soil chemical properties and maize growth in southeastern nigerian ultisol using spent grain ash. In: Proceeding of the 8th international conference on environmental science and technology 2–9:2

Crosier JD (2014) Agricultural utilization of brewers’ spent grains & sawdust: effects on fertility of soils and productivity of crops, Dissertation, Ohio University

Beesigamukama D, Mochoge B, Korir N, Ghemoh CJ, Subramanian S, Tanga CM (2021) In situ nitrogen mineralization and nutrient release by soil amended with black soldier fly frass fertilizer. Sci Rep 11:14799. https://doi.org/10.1038/s41598-021-94269-3

Bootklad M, Chantarak S, Kaewtatip K (2016) Novel biocomposites based on wheat gluten and rubber wood sawdust. J Appl Polym Sci. https://doi.org/10.1002/app.43705

Saepoo T, Sarak S, Mayakun J, Eksomtramage T, Kaewtatip K (2023) Thermoplastic starch composite with oil palm mesocarp fiber waste and its application as biodegradable seeding pot. Carbohydr Polym 299:120221. https://doi.org/10.1016/j.carbpol.2022.120221

Acknowledgements

The authors would like to thank the Graduate School and the Kasetsart University Research and Development Institute for financial support. In addition, the authors are greatly appreciated to the Department of Packaging and Materials Technology for its support throughout this study. The constructive comments from all reviewers are also appreciated.

Author information

Authors and Affiliations

Contributions

LJ Conceptualization, Funding acquisition, Methodology, Validation, Writing—original draft, CK Conceptualization, Methodology, Investigation, NB Conceptualization, Validation, Writing—original draft, Review & editing. All authors listed have made a significant, direct, and intellectual contribution to the work and have given their permission for it to be published.

Corresponding author

Ethics declarations

Conflict of interest

No potential conflict of interest was reported by the authors.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Statement of Novelty: Brewer's spent grain biodegradable plant pots showed promise. Composition ratio affects pot strength, nutritional release, and formation, while biodegradation increases soil nitrogen and organic matter.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Jarupan, L., Kruakam, C. & Bumbudsanpharoke, N. Valorization of brewer's spent grains to produce nutrient biodegradable plant pot. J Mater Cycles Waste Manag 26, 501–511 (2024). https://doi.org/10.1007/s10163-023-01845-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10163-023-01845-y