Abstract

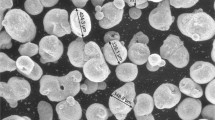

Many WGBs (Waste Glass Bottles) have been disposed in landfill by conventional recycling process, and thereby the recycling process requires improvement to increase the recycling rate. In this study, the WGBs recycling process which can produce cullet and recycled glass aggregate was developed, and Color sorting and crushing experiments were applied. Color sorting experiments with changing the order of the color to be selected showed that sequences of condition IV (Amber–Green–Amber & Green) was satisfied with all color mixture quality standard. The crushing experiments with hammer crusher, shredder, roll crusher, VSI (Vertical Shaft Impact) crusher showed that the only VSI crusher products were satisfied with the particle size quality standard. Moreover, the aspect ratio of VSI crusher products were investigated to identify the possibility of usage as a recycled glass aggregate, and it was confirmed that the aspect ratio of the glass is similar to natural sand. Based on the results, it was possible to produce about 83% of the cullet through color sorting sequence, and about 14% of the recycled glass aggregate could be produced through the crushing/classification process. Therefore, the developed process can improve the recycling rate of WGBs up to 97.1%.

.

Similar content being viewed by others

References

Kalargaris I, Tian G, Gu S (2017) Combustion, performance and emission analysis of a DI diesel engine using plastic pyrolysis oil. Fuel Process Technol 157:108–115. https://doi.org/10.1016/j.fuproc.2016.11.016

Matins LS, Guimaraes LF, Junior ABB, Tenorio JAS, Espinso DCR (2021) Electric car battery: an overview on global demand, recycling and future approaches towards sustainability. J Environ Manage. 295:113091. https://doi.org/10.1016/j.jenvman.2021.113091

Hadi P, Xu M, Lin CSK, Hui C-W, McKay G (2015) Waste printed circuit board recycling technuques and product utilization. J Hazard Mater. 283:234–243. https://doi.org/10.1016/j.jhazmat.2014.09.032

Korean Statistical Information Service (2020) Recycling performance of designated recycling business operator. https://kosis.kr/statHtml/statHtml.do?orgId=392&tblId=DT_CO01&vw_cd=MT_ZTITLE&l ist_id=T_22&seqNo=&lang_mode=ko&language=kor&obj_var_id=&itm_id=&conn_path=MT_ZTITLE. Accessed 24 December 2021

Korea Environment Corporation (2014) Guidelines for the fulfillment of recycling obligations. https://www.keco.or.kr/kr/business/resource/contentsid/1563/index.do. Accessed 1 July 2021

Bai J, Yang X, Xu S, Jing W, Yang J (2014) Preparation of foam glass from waste glass and fly ash. Mater Lett 136:52–54. https://doi.org/10.1016/j.matlet.2014.07.028

König J, Petersen RR, Yue Y (2015) Fabrication of highly insulating foam glass made from CRT panel glass. Ceram Int 41:9793–9800. https://doi.org/10.1016/j.ceramint.2015.04.051

Chen M, Zhang F-S, Zhu J (2009) Lead recovery and the feasibility of foam glass production from funnel glass of dismantled cathode ray tube through pyrovacuum process. J Hazard Mater 161:1109–1113. https://doi.org/10.1016/j.jhazmat.2008.04.084

Hesky D, Aneziris CG, Groß U, Horn A (2015) Water and water glass mixtures for foam glass production. Ceram Int 41:12604–12613. https://doi.org/10.1016/j.ceramint.2015.06.088

Chen G, Lee H, Young KL, Yue PL, Wong A, Tao T, Choi KK (2002) Glass recycling in cement production—an innovative approach. Waste Manage 22:747–753. https://doi.org/10.1016/S0956-053X(02)00047-8

Islam GS, Rahman M, Kazi N (2017) Waste glass powder as partial replacement of cement for sustainable concrete practice. Int J Sustain Built Environ 6:37–44. https://doi.org/10.1016/j.conbuildmat.2016.08.016

Polley C, Cramer SM, de la Cruz RV (1998) Potential for using waste glass in Portland cement concrete. J Mater Civil Eng 10:210–219. https://doi.org/10.1061/(ASCE)0899-1561(1998)10:4(210)

Vijayakumar G, Vishaliny H, Govindarajulu D (2013) Studies on glass powder as partial replacement of cement in concrete production. Int J Emerg Technol Adv Eng 3:153–157

Jin W, Meyer C, Baxter S (2000) “Glascrete”-concrete with glass aggregate. ACI Mater J. 97:208–213. https://doi.org/10.14359/825

Idir R, Cyr M, Tagnit-Hamou A (2010) Use of fine glass as ASR inhibitor in glass aggregate mortars. Constr Build Mater 24:1309–1312. https://doi.org/10.1016/j.conbuildmat.2009.12.030

Gautam S, Srivastava V, Agarwal V (2012) Use of glass wastes as fine aggregate in concrete. J Acad Indus Res 1:320–322

Corinaldesi V, Gnappi G, Moriconi G, Montenero A (2005) Reuse of ground waste glass as aggregate for mortars. Waste Manage 25:197–201. https://doi.org/10.1016/j.wasman.2004.12.009

Kou S, Poon CS (2009) Properties of self-compacting concrete prepared with recycled glass aggregate. Cement Concr Compos 31:107–113. https://doi.org/10.1016/j.cemconcomp.2008.12.002

Shao Y, Lefort T, Moras S, Rodriguez D (2000) Studies on concrete containing ground waste glass. Cem Concr Res 30:91–100. https://doi.org/10.1016/s0008-8846(99)00213-6

Park S-B, Lee B-C (2004) Studies on expansion properties in mortar containing waste glass and fibers. Cem Concr Res 34:1145–1152. https://doi.org/10.1016/j.cemconres.2003.12.005. (Get rights and content)

Lu J-x, Duan Z-h, Poon CS (2017) Combined use of waste glass powder and cullet in architectural mortar. Cem Concr Compos 82:34–44. https://doi.org/10.1016/j.cemconcomp.2017.05.011

Du H, Tan KH (2013) Use of waste glass as sand in mortar: Part II–Alkali–silica reaction and mitigation methods. Cem Concr Compos 35:118–126. https://doi.org/10.1016/j.cemconcomp.2012.08.029

Tan KH, Du H (2013) Use of waste glass as sand in mortar: part I-Fresh, mechanical and durability properties. Cem Concr Compos 35:109–117. https://doi.org/10.1016/j.cemconcomp.2012.08.028

Lu J-X, Poon CS (2018) Use of waste glass in alkali activated cement mortar. Constr Build Mater 160:399–407. https://doi.org/10.1016/j.conbuildmat.2017.11.080

Lee H (2019) Optimization of color sorting process of shredded ELV bumper using reaction surface method. J. of Korean Inst. Res Recycl. 28:23–30. https://doi.org/10.7844/kirr.2019.28.2.23

Korea standard (2020) KS F2526 notice; Concrete aggregate. https://e-ks.kr/streamdocs/view/sd;streamdocsId=72059201946145309. Accessed 14 December 2020

British Standards Institution (1975) BS 812: Part 1. Methods for determination of particle size and shape. Linford Wood, London

Acknowledgements

This project was supported by the Korea Environmental Industry & Technology Institute (KEITI) [2022003490003] and the Korea Institute of Energy Technology Evaluation and Planning (KETEP) [20221B1010003A].

Author information

Authors and Affiliations

Contributions

All authors contributed to the study conception and design. Material preparation, data collection and analysis were performed by all authors. The first draft of the manuscript was written by HL and all authors commented on previous versions of the manuscript. All authors read and approved the final manuscript.

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Lee, H., Kim, K. & Lee, H. The process development of cullet and recycled glass aggregate for improving waste glass bottles recycling rate. J Mater Cycles Waste Manag 25, 3217–3227 (2023). https://doi.org/10.1007/s10163-023-01725-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10163-023-01725-5