Abstract

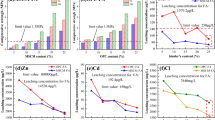

MgO-based cementitious material (MCM) is a potential green substitute for solidifying municipal solid waste incineration fly ash (MSWI FA). Sodium hexametaphosphate (SHMP), a commonly used dispersant, has a great influence on the hydration process of MCM-MSWI FA blends. In this study, the effect of different SHMP additions on the performance of the MCM-MSWI FA (3:7 in mass ratio) blends was investigated. The compressive strength and leaching toxicity of the blends were measured, and the structural evolution was analyzed by XRD, FTIR, TG/DTG, and SEM. These tests revealed that the addition of SHMP could significantly optimize the effect of MCM solidifying MSWI FA since SHMP could promote the dispersion of hydration products in the blends. The blends containing more than 1% SHMP exhibited immobilization efficiencies higher than 97.5% for heavy metals (Cd, Pb, and Zn) after curing for 28 days. Collectively, this work demonstrates the indispensable role of SHMP in the application of MCM solidifying MSWI FA, providing theoretical support for practical engineering.

Similar content being viewed by others

Data Availability

The data underlying this article are available in the article and in its online supplementary material.

References

Zhang Y, Wang L, Chen L, Ma B, Zhang Y, Ni W, Tsang DCW (2021) Treatment of municipal solid waste incineration fly ash: state-of-the-art technologies and future perspectives. J Hazard Mater 411:125132. https://doi.org/10.1016/j.jhazmat.2021.125132

Shao Y, Shao Y, Zhang W, Zhu Y, Dou T, Chu L, Liu Z (2022) Preparation of municipal solid waste incineration fly ash-based ceramsite and its mechanisms of heavy metal immobilization. Waste Manag 143:54–60. https://doi.org/10.1016/j.wasman.2022.02.021

Tan J, Dan H, Li J (2022) Use of municipal waste incineration fly ashes (MSWI FA) in metakaolin-based geopolymer. Environ Sci Pollut R 29(53):80727–80738. https://doi.org/10.1007/s11356-022-21580-5

Luo Z, Chen L, Zhang M, Liu L, Zhao J, Mu Y (2020) Analysis of melting reconstruction treatment and cement solidification on ultra-risk municipal solid waste incinerator fly ash-blast furnace slag mixtures. Environ Sci Pollut R 27(25):32139–32151. https://doi.org/10.1007/s11356-020-09395-8

Fan C, Wang B, Ai H, Qi Y, Liu Z (2021) A comparative study on solidification/stabilization characteristics of coal fly ash-based geopolymer and Portland cement on heavy metals in MSWI fly ash. J Clean Prod 319:128790. https://doi.org/10.1016/j.jclepro.2021.128790

Zhang Y, Cetin B, Likos WJ, Edil TB (2016) Impacts of pH on leaching potential of elements from MSW incineration fly ash. Fuel 184:815–825. https://doi.org/10.1016/j.fuel.2016.07.089

Sonat C, Unluer C (2019) Development of magnesium–silicate–hydrate (M–S–H) cement with rice husk ash. J Clean Prod 211:787–803. https://doi.org/10.1016/j.jclepro.2018.11.246

Bernard E, Lothenbach B, Rentsch D, Pochard I, Dauzères A (2017) Formation of magnesium silicate hydrates (M–S–H). Phys Chem Earth Parts A/B/C 99:142–157. https://doi.org/10.1016/j.pce.2017.02.005

Ruan S, Unluer C (2016) Comparative life cycle assessment of reactive MgO and Portland cement production. J Clean Prod 137:258–273. https://doi.org/10.1016/j.jclepro.2016.07.071

Jin F, Al-Tabbaa A (2013) Thermogravimetric study on the hydration of reactive magnesia and silica mixture at room temperature. Thermochim Acta 566:162–168. https://doi.org/10.1016/j.tca.2013.05.036

Zhang T, Zou J, Li Y, Jia Y, Cheeseman CR (2020) Stabilization/solidification of strontium using magnesium silicate hydrate cement. Processes 8(2):163. https://doi.org/10.3390/pr8020163

Tonelli M, Martini F, Calucci L, Geppi M, Borsacchi S, Ridi F (2017) Traditional Portland cement and MgO-based cement: A promising combination? Phys Chem Earth Parts A/B/C 99:158–167. https://doi.org/10.1016/j.pce.2017.01.011

Wang B, Fan C (2020) Hydration behavior and immobilization mechanism of MgO–SiO2–H2O cementitious system blended with MSWI fly ash. Chemosphere 250:126269. https://doi.org/10.1016/j.chemosphere.2020.126269

Li Z, Zhang T, Hu J, Tang Y, Niu Y, Wei J, Yu Q (2014) Characterization of reaction products and reaction process of MgO–SiO2–H2O system at room temperature. Constr Build Mater 61:252–259. https://doi.org/10.1016/j.conbuildmat.2014.03.004

Chen J, Li T, Li X, Chou K, Hou X (2016) Some new perspective on the reaction mechanism of MgO–SiO2–H2O system. Int J Appl Ceram Technol 13(6):1164–1172. https://doi.org/10.1111/ijac.12607

Jia Y, Wang B, Wu Z, Han J, Zhang T, Vandeperre LJ, Cheeseman CR (2016) Role of sodium hexametaphosphate in MgO/SiO2 cement pastes. Cement Concrete Res 89:63–71. https://doi.org/10.1016/j.cemconres.2016.08.003

Li Z, Lin L, Yu J, Tang H, Qin J, Qian J (2022) Performance of magnesium silicate hydrate cement modified with dipotassium hydrogen phosphate. Constr Build Mater 323:126389. https://doi.org/10.1016/j.conbuildmat.2022.126389

Zhang T, Vandeperre LJ, Cheeseman CR (2014) Formation of magnesium silicate hydrate (M–S–H) cement pastes using sodium hexametaphosphate. Cement Concrete Res 65:8–14. https://doi.org/10.1016/j.cemconres.2014.07.001

Li Z, Xu Y, Zhang T, Hu J, Wei J, Yu Q (2019) Effect of MgO calcination temperature on the reaction products and kinetics of MgO–SiO2–H2O system. J Am Ceram Soc 102(6):3269–3285. https://doi.org/10.1111/jace.16201

Sonat C, Dung NT, Unluer C (2017) Performance and microstructural development of MgO–SiO2 binders under different curing conditions. Constr Build Mater 154:945–955. https://doi.org/10.1016/j.conbuildmat.2017.08.020

Walling SA, Kinoshita H, Bernal SA, Collier NC, Provis JL (2015) Structure and properties of binder gels formed in the system Mg(OH)2–SiO2–H2O for immobilisation of Magnox sludge. Dalton Trans 44(17):8126–8137. https://doi.org/10.1039/c5dt00877h

Jia Y, Wang B, Wu Z, Zhang T (2017) Effect of CaO on the reaction process of MgO–SiO2–H2O cement pastes. Mater Lett 192:48–51. https://doi.org/10.1016/j.matlet.2017.01.072

Mármol G, Savastano H, Tashima MM, Provis JL (2016) Optimization of the MgO–SiO2 binding system for fiber-cement production with cellulosic reinforcing elements. Mater Design 105:251–261. https://doi.org/10.1016/j.matdes.2016.05.064

Cheng F, Hu Y, Song Q, Nie J, Su J, Chen Y (2022) Effect of curing temperature on the properties of a MgO–SiO2–H2O system prepared using dead-burned MgO. Materials 15(17):6065. https://doi.org/10.3390/ma15176065

British Standards BS EN 196-1:2005 (2005) Methods of testing cement—part 1: determination of strength

Yin K, Li P, Chan WP, Dou X, Wang J (2018) Characteristics of heavy metals leaching from MSWI fly ashes in sequential scrubbing processes. J Mater Cycles Waste 20(1):604–613. https://doi.org/10.1007/s10163-017-0631-3

Long L, Jiang X, Lv G, Chen Q, Liu X, Chi Y, Yan J, Zhao X, Kong L (2020) Characteristics of fly ash from waste-to-energy plants adopting grate-type or circulating fluidized bed incinerators: a comparative study. Energy Sources Part A Recov Util Environ Effects. https://doi.org/10.1080/15567036.2020.1796851

Li X, Yu L, Zhou H, Huang G, Yang C, Wu F, Zhang Y (2021) An environment-friendly pretreatment process of municipal solid waste incineration fly ash to enhance the immobilization efficiency by alkali-activated slag cement. J Clean Prod 290:125728. https://doi.org/10.1016/j.jclepro.2020.125728

Wang L, Chen L, Cho D, Tsang DCW, Yang J, Hou D, Baek K, Kua HW, Poon C (2019) Novel synergy of Si-rich minerals and reactive MgO for stabilisation/solidification of contaminated sediment. J Hazard Mater 365:695–706. https://doi.org/10.1016/j.jhazmat.2018.11.067

Fan C, Wang B, Qi Y, Liu Z (2021) Characteristics and leaching behavior of MSWI fly ash in novel solidification/stabilization binders. Waste Manag 131:277–285. https://doi.org/10.1016/j.wasman.2021.06.011

Liu J, Hu L, Tang L, Ren J (2021) Utilisation of municipal solid waste incinerator (MSWI) fly ash with metakaolin for preparation of alkali-activated cementitious material. J Hazard Mater 402:123451. https://doi.org/10.1016/j.jhazmat.2020.123451

Zhang Y, Li Y, Dai Y, Liu J, Xu Y (2018) Hydration evolution of MgO–SiO2 slurries in the presence of sodium metasilicate. Ceram Int 44(6):6626–6633. https://doi.org/10.1016/j.ceramint.2018.01.070

Jin F, Al-Tabbaa A (2014) Evaluation of novel reactive MgO activated slag binder for the immobilisation of lead and zinc. Chemosphere 117:285–294. https://doi.org/10.1016/j.chemosphere.2014.07.027

Li J, Nong Y, Yin S, Chen Z, Su T, Yu Q (2022) Calcium and magnesium silicate hydrates formed in the presence of sodium hydroxide: insight from experiments and DFT simulation. Mater Today Commun 33:104362. https://doi.org/10.1016/j.mtcomm.2022.104362

Bernard E, Dauzères A, Lothenbach B (2018) Magnesium and calcium silicate hydrates, part II: Mg-exchange at the interface “low-pH” cement and magnesium environment studied in a C–S–H and M–S–H model system. Appl Geochem 89:210–218. https://doi.org/10.1016/j.apgeochem.2017.12.006

Dung NT, Unluer C (2016) Improving the performance of reactive MgO cement-based concrete mixes. Constr Build Mater 126:747–758. https://doi.org/10.1016/j.conbuildmat.2016.09.090

Tian X, Rao F, Morales-Estrella R, Song S (2020) Effects of aluminum dosage on gel formation and heavy metal immobilization in alkali-activated municipal solid waste incineration fly ash. Energ Fuel 34(4):4727–4733. https://doi.org/10.1021/acs.energyfuels.9b04493

Hallam L, Papasergio AE, Lessio M, Veliscek-Carolan J (2021) Phosphate functionalised titania for heavy metal removal from acidic sulfate solutions. J Colloid Interf Sci 600:719–728. https://doi.org/10.1016/j.jcis.2021.05.047

Irannajad M, Kamran Haghighi H, Mohammadjafari A (2016) Heavy metals adsorption by nanozeolites: effect of sodium hexametaphosphate. Environ Earth Sci. https://doi.org/10.1007/s12665-016-5851-7

Tonelli M, Martini F, Calucci L, Fratini E, Geppi M, Ridi F, Borsacchi S, Baglioni P (2016) Structural characterization of magnesium silicate hydrate: towards the design of eco-sustainable cements. Dalton T 45(8):3294–3304. https://doi.org/10.1039/C5DT03545G

Jin F, Al-Tabbaa A (2014) Strength and hydration products of reactive MgO-silica pastes. Cement Concrete Compos 52:27–33. https://doi.org/10.1016/j.cemconcomp.2014.04.003

Zhang T, Zou J, Wang B, Wu Z, Jia Y, Cheeseman C (2018) Characterization of magnesium silicate hydrate (MSH) gel formed by reacting MgO and silica fume. Materials 11(6):909. https://doi.org/10.3390/ma11060909

Yang L, Qian X, Yuan P, Bai H, Miki T, Men F, Li H, Nagasaka T (2019) Green synthesis of zeolite 4A using fly ash fused with synergism of NaOH and Na2CO3. J Clean Prod 212:250–260. https://doi.org/10.1016/j.jclepro.2018.11.259

Sáez Del Bosque IF, Martínez-Ramírez S, Blanco-Varela MT (2014) FTIR study of the effect of temperature and nanosilica on the nano structure of C–S–H gel formed by hydrating tricalcium silicate. Constr Build Mater 52:314–323. https://doi.org/10.1016/j.conbuildmat.2013.10.056

Cheng B, Yao C, Xiong J, Liu X, Zhang H, Zhang S (2020) Effects of sodium hexametaphosphate addition on the dispersion and hydration of pure calcium aluminate cement. Materials 13(22):5229. https://doi.org/10.3390/ma13225229

Vermeulen I, Block C, Van Caneghem J, Dewulf W, Sikdar SK, Vandecasteele C (2012) Sustainability assessment of industrial waste treatment processes: the case of automotive shredder residue. Resour Conserv Recycl 69:17–28. https://doi.org/10.1016/j.resconrec.2012.08.010

Billen P, Verbinnen B, De Smet M, Dockx G, Ronsse S, Villani K, De Greef J, Van Caneghem J, Vandecasteele C (2015) Comparison of solidification/stabilization of fly ash and air pollution control residues from municipal solid waste incinerators with and without cement addition. J Mater Cycles Waste 17(2):229–236. https://doi.org/10.1007/s10163-014-0292-4

Acknowledgements

This study is supported by the National Key Research and Development Program of China (Grant No. 2018YFC1901302), the Innovative Research Groups of the National Natural Science Foundation of China (Grant No. 51621005), Power Construction Corporation of China Science and Technology Project (Grant No. DJ-PTZX-2018-01).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Additional file 1. Table S1

: Leaching concentrations of MCM solidified MSWI FA blends at 7 days (mg/L). Table S2: Leaching concentrations of MCM solidified MSWI FA blends at 14 days (mg/L). Table S3: Leaching concentrations of MCM solidified MSWI FA blends at 28 days (mg/L). Table S4: Costs of the materials. Fig. S1: SEM micrographs of raw materials: a MgO, b silica fume. Fig. S2: XRD pattern of the raw MSWI FA. Fig. S3: SEM images of the raw MSWI FA.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Duan, Y., Zheng, L., Zhao, Y. et al. Improving immobilization efficiency and mechanism analysis of sodium hexametaphosphate on MgO-based cementitious material solidified MSWI FA. J Mater Cycles Waste Manag 25, 1781–1791 (2023). https://doi.org/10.1007/s10163-023-01608-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10163-023-01608-9