Abstract

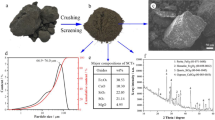

The pozzolanic activity of magnesium-rich nickel slag (HMNS) was improved by remelting and quenching method, the changes of mineralogical phase, microstructure, elements distribution of HMNS remelted and quenched by water were characterized, and the dissolution of Si, Al and Ca required for geopolymerization was also determined. The dissolution amount of Si, Al and Ca for treated HMNS were increased from 1.21, 1.66 and 0.35 mg/g to 6.24, 8.63 and 1.82 mg/g, respectively. From the results of XRD and FTIR, the crystal phases in HMNS after remelting water quenching was transformed into amorphous state, and the substances in treated HMNS mainly existed in the form of vitreous phase. And there was a phase-separated structure of Si-rich region and Ca-rich region on the basis of observation of microstructure and elements distribution. 70wt% of treated HMNS and 30% of FA were used to prepare geopolymer, and found that the compressive strength of geopolymer cured for 28 d was 42.2 MPa, increased by 78.5% compared to the counterpart prepared by untreated HMNS. These results confirm strong effects of the remelting and water quenching treatment on enhancement of pozzolanic activity of HMNS, and could provide help for the utilization of HMNS to prepare geopolymer.

Similar content being viewed by others

Data availability

All the data and material are available in the manuscript.

References

Huang YD, Wang Q, Shi MX (2017) Characteristics and reactivity of ferronickel slag powder. Constr Build Mater 156:773–789

Wei G (2020) Development status and market analysis of nickel industry in China. China Nonferrous Metals 14:44–45

Li XM, Shen M, Wang C, Cui Y, Zhao JX (2017) Current situation and development of comprehensive utilization of nickel slag. Mater Rep 31(05):100–105

Luo ZQ, Ma Y, Mu WH, Liu JH, He J, Zhou XT (2021) Magnesium phosphate cement prepared with electric furnace ferronickel slag: properties and its hydration mechanism. Constr Build Mater 300:123991

Han FH, Zhang HB, Pu SC, Zhang ZQ (2021) Hydration heat and kinetics of composite binder containing blast furnace ferronickel slag at different temperatures. Thermochim Acta 702:178985

Katsiotis NS, Tsakiridis PE, Velissariou D, Katsiotis MS, Alhassan SM, Beazi M (2015) Utilization of ferronickel slag as additive in portland cement: a hydration leaching study. Waste and Biomass Valorization 6:177–189

Bao JW, Yu ZH, Wang LC, Zhang P, Wan XM, Gao S, Zhao TJ (2021) Application of ferronickel slag as fine aggregate in recycled aggregate concrete and the effects on transport properties. J Clean Prod 304:127149

Wang DQ, Wang Q, Zhuang SY, Yang J (2018) Evaluation of alkali-activated blast furnace ferronickel slag as a cementitious material: reaction mechanism, engineering properties and leaching behaviors. Constr Build Mater 188:860–873

Maragkos I, Giannopoulou IP, Panias D (2009) Synthesis of ferronickel slag-based geopolymers. Miner Eng 22:196–203

Sakkas K, Nomikos P, Sofianos A, Panias D (2014) Comprehensive utilization of nickel metallurgical residue. Waste Biomass Valor 5:403–410

Saha AK, Khan MNN, Sarker PK (2018) Value added utilization of by-product electric furnace ferronickel slag as construction materials: a review. Resour Conserv Recycl 134:10–24

van Deventer JSJ, Provis JL, Duxson P, Lukey GC (2007) Reaction mechanisms in the geopolymeric conversion of inorganic waste to useful products. J Hazard Mater 139(03):506–513

Sofi M, van Deventer JSJ, Mendis PA, Lukey GC (2007) Engineering properties of inorganic polymer concretes (IPCs). Cem Concr Res 37(2):251–257

Van Hua Xu JSJ, Deventer, (2000) The geopolymerisation of alumino-silicate minerals. Int J Miner Process 59(3):247–266

Rashad AM, Zeedan SR, Hassan AA (2016) Influence of the activator concentration of sodium silicate on the thermal properties of alkali-activated slag pastes. Constr Build Mater 102:811–820

Saxena R, Gupta T, Sharma RK, Siddique S (2022) Mechanical, durability and microstructural assessment of geopolymer concrete incorporating fine granite waste powder. J Mater Cycles Waste Manage 24:1842–1858

Saxena R, Gupta T (2022) Assessment of mechanical, durability and microstructural properties of geopolymer concrete containing ceramic tile waste. J Mater Cycles Waste Manage 24(2):725–742

Duxson P, Provis JL, Lukey GC, van Deventer JSJ (2007) The role of inorganic polymer technology in the development of ‘green concrete.’ Cem Concr Res 37(12):1590–1597

Provis JL (2018) Alkali-activated materials. Cem Concr Res 114:40–48

Zhang CS, Zhu BG, Li Y, Feng ZZ, Wang Y, Hu ZC (2017) Preparation and characterization of nickel slag/metakaolin based geopolymer. Materials Reports 31(23):193–197

Yang T, Zhang ZH, Zhu HJ (2019) Re-examining the suitability of high magnesium nickel slag as precursors for alkali-activated materials. Constr Build Mater 213:109–120

Zhang ZH, Zhu Y, Yang T (2017) Conversion of local industrial wastes into greener cement through geopolymer technology: a case study of high-magnesium nickel slag. J Clean Prod 141:463–471

Yang T, Wu Q, Zhu H (2017) Geopolymer with improved thermal stability by incorporating high-magnesium nickel slag. Constr Build Mater 155:475–484

Wu QS, Wang SX, Yang T, Zhu HJ, Li SP (2019) Effect of high-magnesium nickel slag on hydration characteristics of Portland cement. J Mater Civil Eng 31(5):04019051

Li BL, Wang S, Pan D, Zhang YM (2019) Hydration Products and Mechanical Properties of Ferronickel Slag Blended Cement Mortar under Xteam Curing. J Chin Ceramic Soc 47(07):891–899

Komnitsas K, Zaharaki D, Perdikatsis V (2007) Geopolymerisation of low calcium ferronickel slags. J Mater Sci 42:3073–3082

Zhang LL, Li SS, Gao Z, Shan HT, Hua SD, Jiang T, Xu ZY (2020) Preparation and performance evaluation of high magnesium nickel slag-phosphogypsum based composite cementitious materials. Cement Eng 04:11–14

Wang YS, Dai JG, Zhu D (2017) Phosphate-based geopolymer: formation mechanism and thermal stability. Mater Lett 190:209–212

Geopolymers DJ (1994) Man-made rock deosynthesis and the resulting development of very early high strength cement. J Mater Edu 16(2–3):91–139

Nath SK, Mukherjee S, Maitra S, Kumar S (2017) Kinetics study of geopolymerization of fly ash using isothermal conduction calorimetry. J Therm Anal Calorim 127(3):1953–1961

Liu Y, Feng CF, Liu Y, Yang SW, Wang MT (2022) Preparation and properties of sodium silicate-Na2CO3-excited magnesium-rich nickel slag-fly ash-based geopolymer. Bulletin Chin Ceramic Soc 41(02):582–588

Pala SC, Mukherjee A, Pathak SR (2003) Investigation of hydraulic activity of ground granulated blast furnace slag in concrete. Cem Concr Res 33:1481–1486

Ganesh Babu K, Sree Rama Kumar V (2000) Efficiency of GGBS in concrete. Cem Concr Res 30:1031–1036

Handke M (1986) Vibrational spectra, force constants, and si-o bond character in calcium silicate crystal structure. Appl Spectrosc 40(6):871–877

Lee WKW, van Deventer JSJ (2007) Chemical interactions between siliceous aggregates and low-Ca alkali-activated cements. Cem Concr Res 37(6):844–855

Criado M, Fernandez-Jimenez A, Palomo A (2007) Alkali activation of fly ash: effect of the SiO2/Na2O ratio.Part 1:FTIR study. Microporous Mesoporous Mater 106:180–191

Ishida K, Jenkins DM, Hawthorne FC (2008) Mid-IR bands of synthetic calcic amphiboles of tremolite-pargasite series and of natural calcic amphiboles. Am Miner 93(7):1112–1118

Zhu WW, Jiang HF, Zhang H, Jia SQ, Liu YD (2018) Effect of TiO2 and CaF2 on the crystallization behavior of Y2O3-Al2O3-SiO2 glass ceramics. Ceram Int 44(6):6653–6658

Zhao J, Lu Y, Kang J (2018) Effect of Y2O3 and La2O3 on structure and dielectricproperties of aluminoborosilicate glasses. J Non-Cryst Solids 496(15):1–5

Li C, Sun HH, Li LT (2011) Glass phase structure of blast furnace slag. Adv Mater Res PTS 1–3(168–170):3–7

Li Y, Liu XM, Sun HH, Cang DQ (2011) Mechanism of phase separation in BFS (blast furnace slag) glass phase. Sci China-Tech Sci 54:105–109

Acknowledgements

This work was supported by the National Natural Science Foundation of China (51974168), Science and Technology Major Project of Inner Mongolia Autonomous Region in China (2019ZD023 and 2021ZD0028) and State Key Laboratory of Silicate Materials for Architectures (Wuhan University of Technology) (SYSJJ2020-08).

Funding

This work was supported by the National Natural Science Foundation of China (51974168), Science and Technology Major Project of Inner Mongolia Autonomous Region in China (2019ZD023 and 2021ZD0028) and State Key Laboratory of Silicate Materials for Architectures (Wuhan University of Technology) (SYSJJ2020-08).

Author information

Authors and Affiliations

Contributions

MW. performed conception, design, analysis and discussion of data, and draft and revise of manuscript. Material preparation, data collection and analysis, first draft of manuscript were performed by YL. Material preparation and data collection were performed by CF, DZ and XZ. Analysis and discussion of data were performed by GJ.

Corresponding authors

Ethics declarations

Conflicts of interest

On behalf of all authors, the corresponding author states that there is no conflict of interest.

Ethics approval

On behalf of all authors, the corresponding author states that there is no ethical issues.

Consent to participate

Mitang Wang performed conception, design, analysis and discussion of data, and draft and revise of manuscript. Material preparation, data collection and analysis, first draft of manuscript were performed by Yun Liu. Material preparation and data collection were performed by Chunfu Feng, Dongliang Zhang and Xiaowei Zhang. Analysis and discussion of data were performed by Guohao Jiao.

Consent for publication

All the authors provide consent for publication.

Research involving human participants and/or animals

Not applicable.

Informed consent

Not applicable.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Wang, M., Liu, Y., Feng, C. et al. Pozzolanic activity enhancement of magnesium-rich nickel slag and geopolymer preparation. J Mater Cycles Waste Manag 24, 2598–2607 (2022). https://doi.org/10.1007/s10163-022-01507-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10163-022-01507-5