Abstract

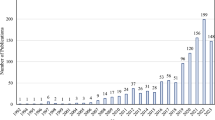

This paper proposes empirical models to straightforwardly assess the CO2 emissions of artificial lightweight aggregate concrete (ALWC) and bottom ash aggregate concrete (BAAC). The system boundary identified for the assessment was from the cradle to pre-construction, considering component materials, production, and transport of concrete. The CO2 emission was empirically formulated as a function of the unit binder content of concrete based on the analysis of a database, which includes 413 and 90 datasets for ALWC and BAAC, respectively. In addition, after applying ALWC and BAAC to concrete structures, their CO2 emissions are compared with those of normal-weight concrete (NWC) structures considering the reduction in the cross-sectional area of members resulting from the lower self-weight of concrete. In this assessment, the concrete used for all structural members is assumed to have been produced using ordinary Portland cement (OPC), featuring a 24 MPa compressive strength. Compared with the evaluated total CO2 emissions of the NWC structures, the ALWC and BAAC structures exhibited 36% and 24% higher CO2 emissions, respectively. This is because the CO2 emission of concrete is considerably dependent on the OPC content but marginally affected by the type of aggregate used.

Similar content being viewed by others

References

Kwon SJ, Yang KH, Mun JH (2018) Flexural tests on externally post-tensioned lightweight concrete beams. Eng Struct 164:128–140

Kim YT, Jeong CS (2011) Production technology, property and application of artificial lightweight aggregates. M Korea Concr Inst 23(5):14–17 (in Korean)

Kim SH, Tae SH, Chae CU (2014) A comparative study on the environmental impacts by concrete strength using end-point LCA methodology. J Korea Concr Inst 26(4):465–474 (in Korean)

Payam S, Salmaliza S, Hafez G, Hilmi BM (2016) Oil palm shell as an agricultural solid waste in artificial lightweight aggregate concrete. Eur J Environ Civ 22:165–180

Carlos L, Arenas C, Luis FV, Fatima A, Yolanda LG (2019) Assessing durability properties of noise barriers made of concrete incorporating bottom ash as aggregates. Eur J Environ Civ 23:1485–1496

Sun JS, Kim JM, Sung JH (2016) Evaluation on the applicability of dry processed bottom ash as lightweight aggregate for construction fields. J Mater Cycles Waste Manag 18:752–762

Yusuf CE, Sedat G, Tuba NI, Osman S, Nigmet U (2020) Life cycle assessment of lightweight concrete containing recycled plastics and fly ash. Eur J Environ Civ. https://doi.org/10.1080/19648189.2020.1767216

Irshidat MR, Al-Nuaimi N, Rabie M (2022) Sustainable alkali-activated binders with municipal solid waste incineration ashes as sand or fly ash replacement. J Mater Cycles Waste Manag. https://doi.org/10.1007/s10163-022-01374-0

Wongsa A, Zaetang Y, Sata V, Chindaprasirt P (2016) Properties of lightweight fly ash geopolymer concrete containing bottom ash as aggregates. Constr Build Mater 111:637–643. https://doi.org/10.1016/j.conbuildmat.2016.02.135

Korea Concrete Institute (2016) Concrete & environment. Korea Concrete Institute, Seoul

Jung YB, Yang KH, Tae SH (2016) Mixture proportioning approach for low-CO2 lightweight aggregate concrete based on the replacement level of natural sand. J Korea Concr Inst 28(4):427–434 (in Korean)

Ji GB, Mun JH, Yang KH (2019) Evaluation of mechanical properties of lightweight concrete using bottom ash aggregates and foam. J Korea Concr Inst 31(4):375–384 (in Korean)

Yang KH, Jung YB (2015) Design approach of concrete structures considering the targeted CO2 reduction. J Rec Const Resour 3(2):115–121 (in Korean)

Ghanbari M, Abbasi AM, Ravanshadnia M (2018) Production of natural and recycled aggregates: the environmental impacts of energy consumption and CO2 emissions. J Mater Cycles Waste Manag 20:810–822

ISO/TC 207/SC 5 (2017) Environmental management-Life cycle assessment—requirements and guidelines—amendment 1(ISO 14044:2006/AMD 1:2017). ISO, Geneva

Yang KH, Seo EA, Tae SH (2014) Carbonation and CO2 uptake of concrete. Environ Impact Assess Rev 46:43–52

Yang KH, Seo EA, Jung YB, Tae SH (2014) Effect of ground granulated blast-furnace slag on life-cycle environmental impact of concrete. J Korea Concr Inst 26(1):13–21 (in Korean)

KEITI (Korea Environmental Industry & Technology Institute) (2017) Ministry of Environment. http://www.epd.or.kr/lci/lci_db.asp. Accessed 13 Dec 2017

KEITI (Korea Environmental Industry & Technology Institute) (2018) Ministry of Land LCI. http://www.g-seed-m.org. Accessed 25 Jan 2018

Tae SH (2014) Development of mix design technique of concrete for reduction of CO2 emission. Technical report. School of Architecture & Architectural Engineering Hanyang University, Seoul, p 87 (in Korean)

Chun HP (2007) A study on the application method of life cycle assessment to evaluate environmental impact in construction. Doctoral thesis. Seoul National University, Seoul (in Korean)

Yang KH, Seo EA (2014) A model for Lifecycle CO2 assessment of building structures considering the mixture proportions of concrete. J Korea Concr Inst 26(2):201–210 (in Korean)

Damineli BL, Kemeid FM, Aguiar PS, John VM (2010) Measuring the ecoefficiency of cement use. Cem Concr Compos 32(8):555–562

Yang KH, Jung YB, Cho MS, Tae SH (2015) Effect of supplementary cementitious materials on reduction of CO2 emissions from concrete. J Clean Prod 103:774–783

Ali MB, Saidur R, Hossain MS (2011) A review on emission analysis in cement industries. Renew Sustain Energy Rev 15:2252–2261

Gartner E (2004) Industrially interesting approaches to “low-CO2” cements. Cem Concr Res 34:1489–1498

Acknowledgements

This work was supported by the Korea Agency for Infrastructure Technology Advancement (KAIA) grant funded by the Ministry of Land, Infrastructure and Transport (Grant No. 21NANO-B156177-02).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The author declares that there is no conflict of interests regarding the publication of this paper.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Jung, YB., Yang, KH. CO2 emission assessment of lightweight aggregate concrete using artificial lightweight and bottom ash particles. J Mater Cycles Waste Manag 24, 2172–2182 (2022). https://doi.org/10.1007/s10163-022-01469-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10163-022-01469-8