Abstract

The asphalt pavement in the Middle East suffers from numerous problems, such as high traffic load, critical climate changes, poor construction quality, and economic problems. These reasons drove researchers to develop modified asphalt binders with excellent performances at a relatively lower cost. Crumb rubber (CR) still has in its early stages in the Middle East countries as an asphalt modifier. The objective of this review is to understand the effect of CR on the performance of asphalt binder and asphalt mixture used in the Middle East countries. The application of CR through the wet process improved the rutting, cracking, and aging resistance of the asphalt mixture. The combination of CR and other materials, such as Styrene–Butadiene–Styrene and Reclaimed Asphalt Pavement, further enhanced the properties of rubberized asphalt. It can be concluded that pavement implemented with rubberized asphalt technology is promising in the Middle East, as it is much more effective than conventional asphalt or other polymer-modified asphalt. For future study, the elasticity modulus and tensile strength of rubberized asphalt in the Middle East are recommended, and the durability of constructed pavement using CR should be evaluated.

Similar content being viewed by others

References

Yousif RA, Kareem QS, Ellk DS (2012) Effect of additives types and contents on permanent deformation. J Eng Sustain Dev 16:258–268

Muniandy R, Jafariahan H, Yunus R, Hassim S (2008) Determination of rheological properties of bio mastic asphalt. Am J Eng Appl Sci 1:204–209

Abu Abdo AM, Jung SJ (2020) Investigation of reinforcing flexible pavements with waste plastic fibers in Ras Al Khaimah, UAE. Road Mater Pavement Des 21:1753–1762

Airey GD (2004) Fundamental binder and practical mixture evaluation of polymer modified bituminous materials. Int J Pavement Eng 5:137–151

Babalghaith AM, Koting S, Ramli Sulong NH, Karim MR (2019) Optimization of mixing time for polymer modified asphalt. IOP Conf Ser Mater Sci Eng 512:1–8

Hesp SAM, Woodhams RT (1991) Asphalt-polyolefin emulsion breakdown. Colloid Polym Sci 269:825–834

Newman JK (1998) Dynamic shear rheological properties of polymer-modified asphalt binders. J Elastomers Plast 30(3):245–263

Abd El-Salam MM, Abu-Zuid GI (2015) Impact of landfill leachate on the groundwater quality: a case study in Egypt. J Adv Res 6:579–586

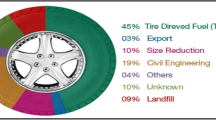

Aljaaidi WM, Almohanna HM, Zaid A, Jumah B (2014) Used tires recycling and utilization in Saudi Arabia

Zoorob SE, Al-Bahar SK, Al-Otaibi SF (2018) Design and optimization of a rubber-bitumen blend in preparation for a rubberized-asphalt road trial in the state of Kuwait. MATEC Web Conf 195:1–10

Bank Q Development (2013) Materials recovery. Environ Stat Annu Rep. https://doi.org/10.1179/000705975798320639

News G Recycling tyres will help save environment. https://gulfnews.com/uae/environment/recycling-tyres-will-help-save-environment-1.112087

Internationale Zusammenarbeit (GIZ) (2014) Country report on the solid waste management in the regional solid waste exchange of information and expertise network in Mashreq and Maghreb countries country report on the solid waste management in jordan

Zarei M, Taghipour H, Hassanzadeh Y (2018) Survey of quantity and management condition of end-of-life tires in Iran: a case study in Tabriz. J Mater Cycles Waste Manag 20:1099–1105

Matar VT& SKI (2017) Solid waste management. Occupied Palestinian Territory

Wamda Rubber a hot commodity for Egypt startup Retyres. https://www.wamda.com/memakersge/2016/06/rubber-a-hot-commodity-for-egypt-startup-retyres.

Chekka L, Management RE and SW Tirevolution resource efficiency and sustainable waste management. https://www.theswitchers.eu/en/switchers/tires-lebanon-recycle-rubber-waste

Weibold (2020) Turkey’s capital will have large tire recycling facility in 2020. https://weibold.com/turkeys-capital-will-have-large-tire-recycling-facility-in-2020

Turkish Statistical Institute (2006) Turkish Statistical Institute Environmental Statistics Compendium of Turkey, II. Ankara

Wazeri A, Khodary F, Ali T, Hozayen HA (2015) Creep stiffness and permanent deformation of rubberized asphalt. Int J Civ Environ Eng 37:1701–8285

Mohammed Babalghaith A, Koting S, Ramli Sulong NH, Karim MR, Mohammed AlMashjary B (2020) Performance evaluation of stone mastic asphalt (SMA) mixtures with palm oil clinker (POC) as fine aggregate replacement. Constr Build Mater 262:120546

Turer A (1999) Recycling of scrap tires. Petrotech. https://doi.org/10.5772/32747

Wu B, Zhou MH (2009) Recycling of waste tyre rubber into oil absorbent. Waste Manag 29:355–359

Sienkiewicz M, Janik H, Borzędowska-Labuda K, Kucińska-Lipka J (2017) Environmentally friendly polymer–rubber composites obtained from waste tyres: a review. J Clean Prod 147:560–571

Zhou H, Holikatti S, Vacura P (2014) Caltrans use of scrap tires in asphalt rubber products: a comprehensive review. J Traffic Transp Eng (English Ed) 1:39–48

Babalghaith AM, Alsoliman HA (2016) Comparison of rheological properties for polymer modified asphalt produced in Riyadh. World Acad Sci Eng Technol 10:197–201

Ruggles CS (2004) The Efficient use of environmentally-friendly natural rubber latex in road construction—past, present and the future, pp 9–12

Miró R, Pérez-jiménez F, Martínez AH, Reyes-ortiz O, Paje SE, Bueno M (2009) Effect of crumb rubber bituminous mixes on functional characteristics of road pavements. Transp Res Rec 2126: 83–90

Fornai D, Sangiorgi C, Mazzotta F, Bermejo JM, Saiz L (2016) A new era for rubber asphalt concretes for the green public procurement in road construction

Świeczko-żurek B, Jaskula P, Ejsmont JA, Kędzierska A, Czajkowski P (2015) Rolling resistance and tire/road noise on rubberized asphalt pavement in rolling resistance and tire/road noise on rubberized asphalt pavement in Poland

Team W Weatheronline. https://www.woweather.com/weather/maps/current?LANG=us&CONT=asie®ION=0023&LAND=KW&LEVEL=4&R=310&CEL=F&ART=karte&TYP=wetter

Al Senafi F, Anis A (2015) Shamals and climate variability in the Northern Arabian/Persian Gulf from 1973 to 2012. Int J Climatol 35:4509–4528

Ramadhan RH, Al-Abdul Wahhab HI (1997) Temperature variation of flexible and rigid pavements in Eastern Saudi Arabia. Build Environ 32:367–373

Sadek H, Masad E, Sirin O, Al-Khalid H, Hassan K (2015) Performance evaluation of full-scale sections of asphalt pavements in the state of Qatar. J Perform Constr Facil 29:04014123

A. Elshaeb M, M. El-Badawy S, A. Shawaly E-S, (2014) Development and impact of the egyptian climatic conditions on flexible pavement performance. Am J Civ Eng Archit 2:115–121

Al-Abdul Wahhab HI, Balghunaim FA (1994) Asphalt pavement temperature related to arid Saudi environment. J Mater Civ Eng 6(1):1–4

Bahia HU, Davies R (1994) Effect of crumb rubber modifiers (CRM) on performance related properties of asphalt binders. Asphalt Pav Technol 63:414–438

Salem HA (2015) Research of the relevant temperatures for the design of pavement constructions on the desert roads in Libya

Mohamed A, Zaltoum A, Kushardjoko W, Yulipriyono EE Evaluation pavement distresses using pavement condition Index (Case Study: Secondary Road in the North east Part of Libya in Koums City), pp 1–8

Zumrawi MME (2015) Investigating causes of pavement deterioration in Khartoum State. Sudan 9:1458–1463

Zumrawi MM (2015) Survey and evaluation of flexible pavement failures. Int J Sci Res 4(1):1602–1607

Othman3 ASMTAA-W and AM (2019) Modeling the raveling propagation in hot and dry climate by using the statistical analysis concepts, pp 868–879

Sirin O, Paul DK, Kassem E, Ohiduzzaman M (2017) Effect of aging on asphalt binders in the state of Qatar: a case study. Asph Paving Technol Assoc Asph Paving Technol Tech Sess 86:215–243

Lee R, Mix-Design A (2020) Rutting, asphalt mix-design, and proposed test road in Saudi Arabia.

Elsharief A (2016) Failure investigation for recently constructed road in Khartoum State. https://doi.org/10.17265/2328-2193/2014.01.003

Anani BA, Balghunaim FA Laboratory and field study of pavement rutting in Saudi Arabia

Venudharan V, Biligiri KP, Sousa JB, Way GB (2017) Asphalt-rubber gap-graded mixture design practices: a state-of-the-art research review and future perspective. Road Mater Pavement Des 18:730–752

Huang B, Mohammad LN, Graves PS, Abadie C (2002) Louisiana experience with crumb rubber-modified hot-mix asphalt pavement. Transp Res Rec 1–13

Maupin GW (1996) Hot mix asphalt rubber applications in Virginia. Transp Res Rec 18–24

Choubane B, Sholar GA, Musselman JA, Page GC (1999) Ten-year performance evaluation of asphalt–rubber surface mixes. Transp Res Rec 10–18

Michel MC, Hayes WC (1993) Fatigue behavior of rubber modified pavements 26

Stroup-Gardiner M, Chadbourn B, Newcomb DE (1996) Babbitt, Minnesota: case study of pretreated crumb rubber modified asphalt concrete. Transp Res Rec 34–42

Babalghaith AM, Alsolieman HA, Al-Suhaibani AS, Koting S (2020) Master curve of dynamic modulus for modified asphalt mixtures. AIP Conf Proc. https://doi.org/10.1063/5.0027224

Development HC for R High commission for Riyadh development wins asphalt award. https://english.mubasher.info/news/2200719/High-Commission-for-Riyadh-Development-wins-asphalt-award/

Ishai I, Amit M, Kesler T, Peled R (2015) New advancements in rubberized asphalt using an elastomeric asphalt extender—three case studies. Rubberized Asph Rubber 4:1–24

Santagata E, Sebaaly H, Idris OEM, Ali MHMM, Al-Emadi KMI (2020) Use of crumb rubber modified binders and asphalt mixtures in public works authority road projects—State of Qatar, pp 512–521

Nunoo CN, Al-Tamimi SA (2020) Implementation of crumb rubber modified binder for qatar local roads construction projects, pp 403–412

Agency EN For the first time, UAE uses rubber asphalt on federal roads. http://wam.ae/en/details/1395302759051

Kuwait institute scientific research KISR implements a rubber asphalt project. http://www.kisr.edu.kw/en/news/156/details/

Keymanesh MR, Ziari H, Damyar B, Shahriari N (2017) Effect of waste EVA (ethylene vinyl acetate) and waste CR (crumb rubber) on characteristics of bitumen. Pet Sci Technol 35:2121–2126

Shafabakhsh GH, Sadeghnejad M, Sajed Y (2014) Case study of rutting performance of HMA modified with waste rubber powder. Case Stud Constr Mater 1:69–76

Khiavi AK, Bakhshi B, Hojjat V (2018) Evaluating the rutting performance of geosynthetic reinforced pavement containing rubberized asphalt mixtures. J Test Eval 46:610–623

Nanjegowda VH, Biligiri KP (2020) Resources, conservation and recycling recyclability of rubber in asphalt roadway systems: a review of applied research and advancement in technology. Resour Conserv Recycl 155:104655

Ali Khasawneh M, Taamneh M, Al-Omari AA, Harahsheh T, Al-Hosainat A (2020) Experimental and statistical evaluation of asphalt binders produced in jordan treated with different modifiers. J Mater Civ Eng 32:04019342

Nejad FM, Aghajani P, Modarres A, Firoozifar H (2012) Investigating the properties of crumb rubber modified bitumen using classic and SHRP testing methods. Constr Build Mater 26:481–489

Ameli A, Norouzi N, Khabbaz EH, Babagoli R (2020) Influence of anti stripping agents on performance of binders and asphalt mixtures containing crumb rubber and styrene–butadiene–rubber. Constr Build Mater 261:119880

Shirini B, Imaninasab R (2016) Performance evaluation of rubberized and SBS modified porous asphalt mixtures. Constr Build Mater 107:165–171

Er A, Karacasu M (2014) CR-10 and CR-15 modifiye bitümlerinin asfalt betonunun performansına etkisi. Ekoloji 23:50–56

Qasim GJ, Tayh SA, Yousif RA (2019) Influence of tire crumb rubber on properties of asphalt binders. IOP Conf Ser Mater Sci Eng. https://doi.org/10.1088/1757-899X/518/2/022066

Aflaki S, Tabatabaee N (2009) Proposals for modification of Iranian bitumen to meet the climatic requirements of Iran. Constr Build Mater 23:2141–2150

Amin MN, Khan MI, Saleem MU (2016) Performance evaluation of asphalt modified with municipal wastes for sustainable pavement construction. Sustain 8:1–13

Darwesh RLM (2018) Modification of Iraqi Asphalt 40/50 properties using saw dust (SD) and natural rubber latex. Al-Mustansiriyah J Sci 28:173

Zoorob SE, Al-Bahar S (2018) Preliminary rheological characterization of tyre derived crumb rubber blended with Kuwaiti Bitumen. MATEC Web Conf 203:1–11

Khan IM, Kabir S, Alhussain MA, Almansoor FF (2016) Asphalt design using recycled plastic and crumb-rubber waste for sustainable pavement construction. Proc Eng 145:1557–1564

Ziari H, Amini A, Goli A (2020) Investigation of blending conditions effect on GTR dissolution and rheological properties of rubberized binders. Constr Build Mater 242:117828

Cheng H, Sun L, Wang Y, Chen X (2021) Effects of actual loading waveforms on the fatigue behaviours of asphalt mixtures. Int J Fatigue 151:106386

Hajikarimi P, Aflaki S, Hoseini AS (2013) Implementing fractional viscoelastic model to evaluate low temperature characteristics of crumb rubber and gilsonite modified asphalt binders. Constr Build Mater 49:682–687

Tuncan M, Tuncan A, Cetin A (2003) The use of waste materials in asphalt concrete mixtures. Waste Manag Res 21:83–92

Karacasua M, Er A, Okur V (2012) Energy efficiency of rubberized asphalt concrete under low-temperature conditions. Proc Soc Behav Sci 54:1242–1249

Karacasu M, Okur V, Er A (2015) A study on the rheological properties of recycled rubber-modified asphalt mixtures. Sci World J. https://doi.org/10.1155/2015/258586

Yan C, Lv Q, Zhang AA, Ai C, Huang W, Ren D (2022) Modeling the modulus of bitumen/SBS composite at different temperatures based on kinetic models. Compos Sci Technol 218:109146

Acknowledgements

This study was supported by the National Natural Science Foundation of China under Project No. 51861145402.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

All authors declare that they have no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Badughaish, A., Wang, J., Hettiarachchi, C. et al. A review on the crumb rubber-modified asphalt in the Middle East. J Mater Cycles Waste Manag 24, 1679–1692 (2022). https://doi.org/10.1007/s10163-022-01455-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10163-022-01455-0