Abstract

Drinking water treatment sludge (DWTS) is a waste industrial material from treatment processes used in drinking water treatment plants (DWTPs) that is produced in large and increasing quantities around the world. Effective and environmentally friendly alternatives to burial and combustion should be investigated to solve the problem of DWTS disposal. The main purpose of this study is to investigate the feasibility of DWTS reuse as a reinforcement material in sandy soil (SS) with full-scale laboratory model tests. The addition of 18% DWTS increased the load capacity–settlement curves by a factor of approximately 1.24. This was sufficient to improve SS to a depth of 2.5 times the footing diameter. Therefore, DWTS can be used as a base fill material for SS improvement. Additionally, scanning electron microscopy (SEM) revealed that gaps in SS were filled with DWTS, and a more rigid structure was formed. These results show that DWTS can be considered an alternative waste additive material for the improvement of SS.

Graphical abstract

Similar content being viewed by others

Availability of data and materials

The data generated or analysed during this study are included in this published article and are available from the corresponding author [Esra Deniz Güner] on reasonable request.

References

Dassanayake K, Jayasinghe G, Surapaneni A, Hetherington C (2015) A review on alum sludge reuse with special reference to agricultural applications and future challenges. Waste Manage 38:321–335

Lee H, Hanif A, Usman M, Sim J, Oh H (2018) Performance evaluation of concrete incorporating glass powder and glass sludge wastes as supplementary cementing material. J Clean Prod 170:683–693

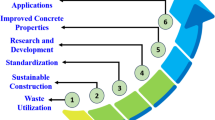

Gomes SDC, Zhou JL, Li W, Long G (2019) Progress in manufacture and properties of construction materials incorporating water treatment sludge: a review. Resour Conserv Recycl 145:148–159

Ahmad T, Ahmad K, Alam M (2016) Characterization of water treatment plant’s sludge and its safe disposal options. Procedia Environ Sci 35:950–955

Ahmad T, Ahmad K, Ahad A, Alam M (2016) Characterization of water treatment sludge and its reuse as coagulant. J Environ Manage 182:606–611

Jung K-W, Hwang M-J, Park D-S, Ahn K-H (2016) Comprehensive reuse of drinking water treatment residuals in coagulation and adsorption processes. J Environ Manage 181:425–434

de Godoy LGG, Rohden AB, Garcez MR, Da Dalt S, Gomes LB (2020) Production of supplementary cementitious material as a sustainable management strategy for water treatment sludge waste. Case Stud Constr Mater 12:e00329

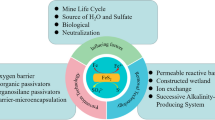

Hidalgo A, Murcia M, Gomez M, Gomez E, Garcia-Izquierdo C, Solano C (2017) Possible uses for sludge from drinking water treatment plants. J Environ Eng 143(3):04016088

de Oliveira Andrade JJ, Wenzel MC, da Rocha GH, da Silva SR (2018) Performance of rendering mortars containing sludge from water treatment plants as fine recycled aggregate. J Clean Prod 192:159–168

Kaish A, Breesem KM, Abood MM (2018) Influence of pre-treated alum sludge on properties of high-strength self-compacting concrete. J Clean Prod 202:1085–1096

Algamal Y, Khalil NM, Saleem QM (2018) Usage of the sludge from water treatment plant in brick-making industry. J Chem Technol Metall 53(3):504–510

Cremades L, Cusidó J, Arteaga F (2018) Recycling of sludge from drinking water treatment as ceramic material for the manufacture of tiles. J Clean Prod 201:1071–1080

Ewais E, Elsaadany R, Ahmed A, Shalaby N, Al-Anadouli B (2017) Insulating refractory bricks from water treatment sludge and rice husk ash. Refract Ind Ceram 58(2):136–144

Wolff E, Schwabe WK, Conceição SV (2015) Utilization of water treatment plant sludge in structural ceramics. J Clean Prod 96:282–289

Geraldo RH, Fernandes LF, Camarini G (2017) Water treatment sludge and rice husk ash to sustainable geopolymer production. J Clean Prod 149:146–155

Sato Y, Oyamada T, Hanehara S, Sasakı T (2012) The characteristics of ash of sewage sludge (SSA) in iwate prefecture and application of SSA for asphalt mixture. J Min Mater Process Inst Jpn 128(8_9):519–525

González-Corrochano B, Alonso-Azcárate J, Rodríguez L, Pérez Lorenzo A, Fernández Torío M, Tejado Ramos JJ, Corvinos MD, Muro C (2018) Effect heating dwell time has on the retention of heavy metals in the structure of lightweight aggregates manufactured from wastes. Environ Technol 39(19):2511–2523

Huang C-H, Wang S-Y (2013) Application of water treatment sludge in the manufacturing of lightweight aggregate. Constr Build Mater 43:174–183

Arulrajah A, Mohammadinia A, Phummiphan I, Horpibulsuk S, Samingthong W (2016) Stabilization of recycled demolition aggregates by geopolymers comprising calcium carbide residue, fly ash and slag precursors. Constr Build Mater 114:864–873

Arulrajah A, Yaghoubi E, Wong YC, Horpibulsuk S (2017) Recycled plastic granules and demolition wastes as construction materials: resilient moduli and strength characteristics. Constr Build Mater 147:639–647

Disfani MM, Tsang H-H, Arulrajah A, Yaghoubi E (2017) Shear and compression characteristics of recycled glass-tire mixtures. J Mater Civ Eng 29(6):06017003

Du Y-J, Jiang N-J, Liu S-Y, Horpibulsuk S, Arulrajah A (2016) Field evaluation of soft highway subgrade soil stabilized with calcium carbide residue. Soils Found 56(2):301–314

Horpibulsuk S, Suksiripattanapong C, Samingthong W, Rachan R, Arulrajah A (2016) Durability against wetting–drying cycles of water treatment sludge–fly ash geopolymer and water treatment sludge–cement and silty clay–cement systems. J Mater Civ Eng 28(1):04015078

Jiang N-J, Du Y-J, Liu S-Y, Wei M-L, Horpibulsuk S, Arulrajah A (2015) Multi-scale laboratory evaluation of the physical, mechanical, and microstructural properties of soft highway subgrade soil stabilized with calcium carbide residue. Can Geotech J 53(3):373–383

Kang X, Ge L, Liao W-C (2016) Cement hydration-based micromechanics modeling of the time-dependent small-strain stiffness of fly ash-stabilized soils. Int J Geomech 16(3):04015071

Latifi N, Meehan CL, Majid MZA, Horpibulsuk S (2016) Strengthening montmorillonitic and kaolinitic clays using a calcium-based non-traditional additive: a micro-level study. Appl Clay Sci 132:182–193

Latifi N, Rashid ASA, Ecemis N, Tahir MM, Marto A (2016) Time-dependent physicochemical characteristics of Malaysian residual soil stabilized with magnesium chloride solution. Arab J Geosci 9(1):58

Latifi N, Rashid ASA, Marto A, Tahir MM (2016) Effect of magnesium chloride solution on the physico-chemical characteristics of tropical peat. Environ Earth Sci 75(3):220

Maghool F, Arulrajah A, Horpibulsuk S, Du Y-J (2017) Laboratory evaluation of ladle furnace slag in unbound pavement-base/subbase applications. J Mater Civ Eng 29(2):04016197

Neramitkornburi A, Horpibulsuk S, Shen S, Arulrajah A, Disfani MM (2015) Engineering properties of lightweight cellular cemented clay−fly ash material. Soils Found 55(2):471–483

Rios S, Cristelo N, Viana da Fonseca A, Ferreira C (2017) Stiffness behavior of soil stabilized with alkali-activated fly ash from small to large strains. Int J Geomech 17(3):04016087

Sukmak P, De Silva P, Horpibulsuk S, Chindaprasirt P (2015) Sulfate resistance of clay-portland cement and clay high-calcium fly ash geopolymer. J Mater Civ Eng 27(5):04014158

Rajeswari K, Naidu CD, Rao KB, Kumari GH (2018) Study of soil stabalization on subgrade using bagasse ash and phosphogypsum. Int J Technol Res Eng 5(6):3133–3142

Suksiripattanapong C, Kua T-A, Arulrajah A, Maghool F, Horpibulsuk S (2017) Strength and microstructure properties of spent coffee grounds stabilized with rice husk ash and slag geopolymers. Constr Build Mater 146:312–320

Liu Y, Chang C-W, Namdar A, She Y, Lin C-H, Yuan X, Yang Q (2019) Stabilization of expansive soil using cementing material from rice husk ash and calcium carbide residue. Constr Build Mater 221:1–11

Rashid ASA, Latifi N, Meehan CL, Manahiloh KN (2017) Sustainable improvement of tropical residual soil using an environmentally friendly additive. Geotech Geol Eng 35(6):2613–2623

Latifi N, Horpibulsuk S, Meehan CL, Abd Majid MZ, Tahir MM, Mohamad ET (2017) Improvement of problematic soils with biopolymer—an environmentally friendly soil stabilizer. J Mater Civ Eng 29(2):04016204

Arulrajah A, Piratheepan J, Disfani MM, Bo MW (2013) Geotechnical and geoenvironmental properties of recycled construction and demolition materials in pavement subbase applications. J Mater Civ Eng 25(8):1077–1088

Karnam Prabhakara BK, Guda PV, Balunaini U (2019) Optimum mixing ratio and shear strength of granulated rubber-fly ash mixtures. J Mater Civ Eng 31(4):04019018

Saberian M, Li J, Cameron D (2019) Effect of crushed glass on behavior of crushed recycled pavement materials together with crumb rubber for making a clean green base and subbase. J Mater Civ Eng 31(7):04019108

Zhang T, Cai G, Liu S, Puppala AJ (2016) Engineering properties and microstructural characteristics of foundation silt stabilized by lignin-based industrial by-product. KSCE J Civ Eng 20(7):2725–2736

Iqbal MR, Hashimoto K, Tachibana S, Kawamoto K (2019) Geotechnical properties of sludge blended with crushed concrete and incineration ash. Geomate J 16(57):116–123

Ayininuola GM, Ayodeji O (2016) Influence of sludge ash on soil shear strength. J Civil Eng Res 6(3):72–77

Ayodele AL, Adebısı AO, Kareem MA (2016) Use of sludge ash in stabilising two tropical laterite. Int J Sci Eng Res 7(8):104–108

de Figueirêdo Lopes Lucena LC, Thomé Juca JF, Soares JB, Portela MG (2014) Potential uses of sewage sludge in highway construction. J Mater Civil Eng 26(9):04014051

Shah SAR, Mahmood Z, Nisar A, Aamir M, Farid A, Waseem M (2020) Compaction performance analysis of alum sludge waste modified soil. Constr Build Mater 230:116953

Taki K, Choudhary S, Gupta S, Kumar M (2020) Enhancement of geotechnical properties of municipal sewage sludge for sustainable utilization as engineering construction material. J Clean Prod 251:119723

Zhan TL, Zhan X, Lin W, Luo X, Chen Y (2014) Field and laboratory investigation on geotechnical properties of sewage sludge disposed in a pit at Changan landfill, Chengdu, China. Eng Geol 170:24–32

Güllü H, Girisken S (2013) Performance of fine-grained soil treated with industrial wastewater sludge. Environ Earth Sci 70(2):777–788

Lin D-F, Luo H-L, Hsiao D-H, Yang C-C (2005) The effects of sludge ash on the strength of soft subgrade soil. J Chin Inst Environ Eng 15:1–10

Lin D-F, Lin K-L, Hung M-J, Luo H-L (2007) Sludge ash/hydrated lime on the geotechnical properties of soft soil. J Hazard Mater 145(1–2):58–64

Lin D-F, Lin K-L, Luo H-L (2007) A comparison between sludge ash and fly ash on the improvement in soft soil. J Air Waste Manag Assoc 57(1):59–64

Chen L, Lin D-F (2009) Stabilization treatment of soft subgrade soil by sewage sludge ash and cement. J Hazard Mater 162(1):321–327

Tempest BQ, Pando MA (2013) Characterization and demonstration of reuse applications of sewage sludge ash. Geomate J 4(8):552–559

Norouzian K, Abbasi N, Abedi Koupai J (2018) Use of sewage sludge ash and hydrated lime to improve the engineering properties of clayey soils. Geotech Geol Eng 36(3):1575–1586

Kadhim YM, Al-Adhamii RA, Fattah MY (2022) Geotechnical properties of clayey soil improved by sewage sludge ash. J Air Waste Manag Assoc 72(1):34–47

ASTM (2009) A standard test methods for laboratory determination of density (unit weight) of soil specimens. Standard D7263–09

ASTM (2006) A standard test methods for maximum index density and unit weight of soils using a vibratory table. Standard D4253–16

ASTM (2006) A standard test methods for minimum index density and unit weight of soils and calculation of relative density. Standard D4254–16

Guimarães M, Morita D (2003) Incorporação de Lodo de Estações de Tratamento de Água em Blocos Cerâmicos. Iniciação Científica Graduação em Engenharia Civil, Departamento de Engenharia Hidráulica e Sanitária, Universidade de São Paulo, Brasil

Pan J, Huang C, Lin S (2004) Reuse of fresh water sludge in cement making. Water Sci Technol 50(9):183–188

Bagriacik B (2021) Utilization of alkali-activated construction demolition waste for sandy soil improvement with large-scale laboratory experiments. Constr Build Mater 302:124173

Anastasiadis A, Senetakis K, Pitilakis K (2012) Small-strain shear modulus and damping ratio of sand-rubber and gravel-rubber mixtures. Geotech Geol Eng 30(2):363–382

Sayeed M, Ramaiah BJ, Rawal A (2014) Interface shear characteristics of jute/polypropylene hybrid nonwoven geotextiles and sand using large size direct shear test. Geotext Geomembr 42(1):63–68

Mittal RK, Gill G (2018) Sustainable application of waste tire chips and geogrid for improving load carrying capacity of granular soils. J Clean Prod 200:542–551

Binquet J, Lee KL (1975) Bearing capacity tests on reinforced earth slabs. J Geotech Eng Div 101(12):1241–1255

Mosallanezhad M, Hataf N, Sadat Taghavi S (2016) Experimental and large-scale field tests of grid-anchor system performance in increasing the ultimate bearing capacity of granular soils. Can Geotech J 53(7):1047–1058

Acknowledgements

The author wishes to thank all those who assisted in conducting this work. I also acknowledge that this article is the original work of the author and has not been published before or submitted to another journal for consideration for publication.

Funding

Not applicable.

Author information

Authors and Affiliations

Contributions

EDG designed all experiments, established the system, analysed the results, and wrote the manuscript.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Ethics approval and consent to participate

Not applicable.

Consent for publication

Not applicable.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Güner, E.D. Experimental investigation of the feasibility of using drinking water treatment plant sludge in the improvement of sandy soils. J Mater Cycles Waste Manag 24, 1923–1933 (2022). https://doi.org/10.1007/s10163-022-01448-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10163-022-01448-z