Abstract

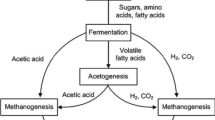

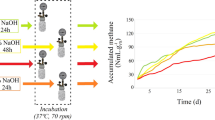

Discarded dry fig and raisin, which exporting companies have to claim and destroy, were subjected to batch dark fermentation at 37 °C with pretreated anaerobic sludge in an incubator to investigate the effect of mycotoxin on biohydrogen production. The need for pretreatment was evaluated. Pretreatment had no significant effect on enhancing biohydrogen production at comparison of the same substrates. However, it had a significant positive effect on comparison of yield ratios when mycotoxin presence was observed. The CHF of dry fig and raisin without pretreatment (81 mL, 56 mL, respectively) was lower than mycotoxin-free substrates (267 mL, 180 mL, respectively). In mycotoxic wastes, the VFA concentration was very high, inhibiting biohydrogen formation. Furthermore, mycotoxins and their by-products after pretreatment may cause the bacterial mechanism to shift into different hydrogen-consuming end products. In mycotoxin-free substrates, there was around 2.2–2.5 g L−1 acetate and 1.1–1.7 g L−1 butyrate, enhancing biohydrogen production potential. The highest biohydrogen production yield was observed with mycotoxin-free dry fig without pretreatment (79 mL H2 g−1 total sugar). The dry fig without mycotoxin produced the highest SHPR (42.3 ml H2 g−1 cell mass h−1). Mycotoxin has a clear negative impact on biohydrogen production potential, biohydrogen production yield, and SHPR.

Similar content being viewed by others

References

Kapdan IK, Kargi F (2006) Bio-hydrogen production from waste materials. Enzyme Microb Technol 38:569–582. https://doi.org/10.1016/j.enzmictec.2005.09.015

Salakkam A, Sittijunda S, Mamimin C, Phanduang O, Reungsang A (2021) Valorization of microalgal biomass for biohydrogen generation: a review. Bioresour Technol 322:124533. https://doi.org/10.1016/j.biortech.2020.124533

Hakobyan L, Gabrielyan L, Blbulyan S, Trchounian A (2021) The prospects of brewery waste application in biohydrogen production by photofermentation of Rhodobacter sphaeroides. Int J Hydrog Energy 46:289–296. https://doi.org/10.1016/j.ijhydene.2020.09.184

Yang E, Mohamed HO, Park SG, Obaid M, Al-Qaradawi SY, Castano P, Chon K, Chae KY (2021) A review on self-sustainable microbial electrolysis cells for electro-biohydrogen production via coupling with carbon-neutral renewable energy technologies. Bioresour Technol 320:124363. https://doi.org/10.1016/j.biortech.2020.124363

Kovalev AA, Kovalev DA, Litti YV, Katraeva IV (2020) Biohydrogen production in the two-stage process of anaerobic bioconversion of organic matter of liquid organic waste with recirculation of digister effluent. Int J Hydrog Energy 45:26831–26839. https://doi.org/10.1016/j.ijhydene.2020.07.124

Shao W, Wang Q, Rupani PF, Krishnan S, Ahmad F, Rezania S, Rashid MA, Sha C, Din MFM (2020) Biohydrogen production via thermophilic fermentation: a prospective application of Thermotoga species. Energy 197:117199. https://doi.org/10.1016/j.energy.2020.117199

Bhatia SK, Jagtap SS, Bedekar AA, Bhatia RK, Rajendran K, Pugazhendhi A, Rao CV, Atabani AE, Kumar G, Yang YH (2021) Renewable biohydrogen production from lignocellulosic biomass using fermentation and integration of systems with other energy generation technologies. Sci Total Environ 765:144429. https://doi.org/10.1016/j.scitotenv.2020.144429

Watanabe H, Yoshino H (2011) Biohydrogen using leachate from an industrial waste landfill as inoculums. J Mater Cycles Waste Manag 13:113–117

Ghosh S, Roy S (2019) Novel integration of biohydrogen production with fungal biodiesel production process. Bioresour Technol 288:121603. https://doi.org/10.1016/j.biortech.2019.121603

Azwar MY, Hussain MA, Abdul-Wahab AK (2014) Development of biohydrogen production by photobiological, fermentation and electrochemical processes: a review. Renew Sustain Energy Rev 31:158–173. https://doi.org/10.1016/j.rser.2013.11.022

Kapdan IK, Kargi F, Oztekin R, Argun H (2009) Bio-hydrogen production from acid hydrolyzed wheat starch by photo-fermentation using different Rhodobacter sp. Int J Hydrog Energy 34:2201–2207. https://doi.org/10.1016/j.ijhydene.2009.01.017

Hussy I, Hawkes FR, Dinsdale R, Hawkes DL (2003) Continuous fermentative hydrogen production from a wheat starch co-product by mixed microflora. Biotechnol Bioeng 84:619–626. https://doi.org/10.1002/bit.10785

Lee M-J, Zhang S, Cho Y-B, Park J-E, Chang K-H, Hwang S-J (2015) Effects of nitrate concentration on biohydrogen production and substrate utilization in dark-fermentation. J of Mater Cycles and Waste Manag 17:27–32

Radhakrishnan R, Banerjee S, Banerjee S, Singh V, Das D (2021) Sustainable approach for the treatment of poultry manure and starchy wastewater by integrating dark fermentation and microalgal cultivation. J Mater Cycles and Waste Manag 23:790–803

Ivanova G, Rakhely G, Kovacs KL (2009) Thermophilic biohydrogen production from energy plants by Caldicellulosiruptor saccharolyticus and comparison with related studies. Int J Hydrog Energy 34:3659–3670. https://doi.org/10.1016/j.ijhydene.2009.02.082

Jiang D, Zhang Y, Lu C, Sun T, Zhang B, Zhang Q (2015) Dynamics of biomass straw enzymolysis and photosynthetic characteristics of biological hydrogen production. Trans Chin Soc Agric Mach 46:196–201. https://doi.org/10.6041/j.issn.1000-1298.2015.05.027

Jiang D, Ge X, Zhang T, Liu H, Zhang Q (2016) Photo-fermentative hydrogen production from enzymatic hydrolysate of corn stalk pith with a photosynthetic consortium. Int J Hydrog Energy 41:16778–16785. https://doi.org/10.1016/j.ijhydene.2016.07.129

Panin S, Setthapun W, Sinsuw AAE, Sintuya H, Chu CY (2021) Biohydrogen and biogas production from mashed and powdered vegetable residues by an enriched microflora in dark fermentation. Int J Hydrog Energy 46:14073–14082. https://doi.org/10.1016/j.ijhydene.2020.09.246

Cao X, Zhao Y (2009) The influence of sodium on biohydrogen production from food waste by anaerobic fermentation. J Mater Cycles and Waste Manag 11:244–250

Bhurat KS, Banerjee T, Pandey JK, Bhurat SS (2021) A lab fermenter level study on anaerobic hydrogen fermentation using potato peel waste: effect of pH, temperature, and substrate pre-treatment. J Mater Cycles and Waste Manag 23:1617–1625

Banu JR, Merrylin J, Usman TMM, Kannah RY, Gunasekaran M, Kim SH, Kumar G (2020) Impact of pretreatment on food waste for biohydrogen production: a review. Int J Hydrog Energy 45:18211–18225. https://doi.org/10.1016/j.ijhydene.2019.09.176

Yasin NHM, Mumtaz T, Hassan M (2013) Food waste and food processing waste for biohydrogen production: a review. J Environ Manag 130:375–385. https://doi.org/10.1016/j.jenvman.2013.09.009

Mahato RK, Kumar D, Rajagopalan G (2020) Biohydrogen production from fruit waste by Clostridium strain BOH3. Renew Energ 153:1368–1377. https://doi.org/10.1016/j.renene.2020.02.092

Wloch WC, Borowski S, Otlewska A (2020) Biohydrogen production from fruit and vegetable waste, sugar beet pulp and corn silage via dark fermentation. Renew Energ 153:1226–1237. https://doi.org/10.1016/j.renene.2020.02.085

Abubackar HN, Keskin T, Yazgin O, Gunay B, Arslan K, Azbar N (2019) Biohydrogen production from autoclaved fruit and vegetable wastes by dry fermentation under thermophilic condition. Int J Hydrog Energy 44:18776–18784. https://doi.org/10.1016/j.ijhydene.2018.12.068

Soares JF, Confortin TC, Todero I, Mayer FD, Mazutti MA (2020) Dark fermentative biohydrogen production from lignocellulosic biomass: technological challenges and future prospects. Renew Sustain Energy Rev 117:109484. https://doi.org/10.1016/j.rser.2019.109484

Dinesh GK, Chauhan R, Chakma S (2018) Influence and strategies for enhanced biohydrogen production from food waste. Renew Sustain Energy Rev 92:807–822. https://doi.org/10.1016/j.rser.2018.05.009

Wijaya YP, Putra RDD, Widyaya VT, Ha JM, Suh DJ, Kim CS (2014) Comparative study on two-step concentrated acid hydrolysis for the extraction of sugars from lignocellulosic biomass. Bioresour Technol 164:221–231. https://doi.org/10.1016/j.biortech.2014.04.084

Xu F, Li Y, Ge X, Yang L, Li Y (2018) Anaerobic digestion of food waste: challenges and oppurtunities. Bioresour Technol 247:1047–1058. https://doi.org/10.1016/j.biortech.2017.09.020

Jayalakshmi S, Joseph K, Sukumaran V (2009) Biohydrogen generation from kitchen waste in an inclined plug flow reactor. Int J Hydrog Energy 34:8854–8858. https://doi.org/10.1016/j.ijhydene.2009.08.048

Li Y, Jin Y (2015) Effects of thermal pretreatment on acidification phase during two-phase batch anaerobic digestion of kitchen waste. Renew Energ 77:550–557. https://doi.org/10.1016/j.renene.2014.12.056

Valderrama SR, Alvarado CE, Magnin JP, Garcia PR, Vazquez IV, Leal ER (2020) Batch biohydrogen production from dilute acid hydrolyzates of fruits and vegetables wastes and corn stover as co-substrates. Biomass Bioenergy 140:105666. https://doi.org/10.1016/j.biombioe.2020.105666

François E, Dumas C, Gougeon RD, Alexandre H, Vuilleumier S, Ernst B (2021) Unexpected high production of biohydrogen from the endogenous fermentation of grape must deposits. Bioresour Technol 320:124334. https://doi.org/10.1016/j.biortech.2020.124334

Cahyari K, Hidayat MS, Syamsiah S, Sarto S (2019) Optimization of hydrogen production from fruit waste through mesophilic and thermophilic dark fermentation: effect of substrate-to-inoculum ratio. Malaysian J Anal Sci 23:116–123. https://doi.org/10.17576/mjas-2019-2301-14

Akinbomi J, Taherzadeh MJ (2015) Evaluation of fermentative hydrogen production from single and mixed fruit wastes. Energies 8:4253–4272. https://doi.org/10.3390/en8054253

Turkey Ministry of Agriculture and Forestry (2021), Grape Assessment Report. https://www.tarimorman.gov.tr/BUGEM/Belgeler/M%C4%B0LL%C4%B0%20TARIM/%C3%9Cr%C3%BCn%20Masalar%C4%B1%20%C3%9Cr%C3%BCn%20De%C4%9Ferlendirme%20Raporlar%C4%B1%20yay%C4%B1mland%C4%B1/%C3%9Cz%C3%BCm%20De%C4%9Ferlendirme%20Raporu.pdf . Accessed 10 February 2021

Turkey Ministry of Agriculture and Forestry (2021) Fig Assessment Report. https://www.tarimorman.gov.tr/BUGEM/Belgeler/M%C4%B0LL%C4%B0%20TARIM/%C3%9Cr%C3%BCn%20Masalar%C4%B1%20%C3%9Cr%C3%BCn%20De%C4%9Ferlendirme%20Raporlar%C4%B1%20yay%C4%B1mland%C4%B1/%C4%B0ncir%20De%C4%9Ferlendirme%20Raporu.pdf. Accessed 10 February 2021

Agriopoulou S, Stamatelopoulou E, Varzakas T (2020) Advances in occurrence, importance, and mycotoxin control strategies: prevention and detoxification in foods. Foods 9:137. https://doi.org/10.3390/foods9020137

Unusan N (2009) Systematic review of mycotoxins in food and feeds in Turkey. Food Control 97:1–14. https://doi.org/10.1016/j.foodcont.2018.10.015

Celiktas MS (2015) Sequential techniques for aflatoxin contaminated Ficus carica L. to produce bioethanol. J Biobased Mater Bioenergy 9:410–416. https://doi.org/10.1166/jbmb.2015.1540

Bakirci GT (2020) Investigation of aflatoxins levels in commercial dried figs from western Turkey. Int Food Res J 27:245–251

Karlovsky P, Suman M, Berthiller F, De Meester J, Eisenbrand G, Perrin I, Oswald IP, Speijers G, Chiodini A, Recker T, Dussort P (2016) Impact of food processing and detoxification treatments on mycotoxin contamination. Mycotoxin Res 32:179–205

Jalili M, Jinap S, Son R (2011) The effect of chemical treatment on reduction of aflatoxins and ochratoxin A in black and white pepper during washing. Food Addit Contam Part A Chem Anal Control Expo Risk Assess 28(4):485–93

Sipos P, Peles F, Brassó DL, Béri B, Pusztahelyi T, Pócsi I, Gyõri Z (2021) Physical and chemical methods for reduction in aflatoxin content of feed and food. Toxins 13:204

Arvaniti OS, Samaras Y, Gatidou G, Thomaidis NS, Stasinakis AS (2019) Review on fresh and dried figs: chemical analysis and occurrence of phytochemical compounds, antioxidant capacity and health effects. Food Res Int 119:244–267. https://doi.org/10.1016/j.foodres.2019.01.055

Suman PM, Berthiller F, De Meester J, Eisenbrand G, Perrin I, Oswald IP, Speijers G, Chiodini A, Recker T, Dussort P (2016) Impact of food processing and detoxification treatments on mycotoxin contamination. Mycotoxin Res 32:179–205

TURKOMP National Food Composition Database (2021) http://www.turkomp.gov.tr/food-incir-kuru-izmir-529. Accessed 12 February 2021

Khiari R, Zemni H, Mihoubi D (2019) Raisin processing: physicochemical, nutritional and microbiological quality characteristics as affected by drying process. Food Rev Int 35:246–298. https://doi.org/10.1080/87559129.2018.1517264

Alnuwaiser MA (2017) Content of sugars in fresh grapes and raisins, and fresh and dried apricot: a comparative study. Int J Res Granthaalayah 5:177–186. https://doi.org/10.5281/zenodo.1095050

Ozmihci S, Kargi F (2010) Effects of starch loading rate on performance of combined fed-batch fermentation of ground wheat for bio-hydrogen production. Int J of Hydrogen Energy 35(3):1106–1111

Dubois MG, Gilles KA, Hamilton JK (1956) Colorimetric method for determination of sugars and related substances. Anal Chem 28:350–358

R-biopharm (2004) Ridascreen® Histamine instruction manual for the histamine ELISA kit R- Biopharm AG, Landwehrstrasse 54 D-64293 Darmstadt, Germany

R-biopharm (2005) Ridascreen® Histamine instruction manual for the histamine ELISA kit R- Biopharm AG, Landwehrstrasse 54 D-64293 Darmstadt, Germany

Vicam LP (1999) Fluorometer USDA-FGIS procedure for corn, corn meal, corn/soy blend, milled rice, popcorn, sorghum and soybeans. Afla Test Instruction Manuel, USA

Argun H, Kargi F, Kapdan IK, Oztekin R (2008) Batch dark fermentation of powdered wheat starch to hydrogen gas: effects of the initial substrate and biomass concentrations. Int J Hydrog Energy 33:6109–6115. https://doi.org/10.1016/j.ijhydene.2008.08.004

Shetty PH, Jespersen L (2006) Saccharomyces cerevisiae and lactic acid bacteria as potential mycotoxin decontaminating agents. Trends Food Sci Technol 17(2):48–55

Bueno DJ, Casale CH, Pizzolitto RP, Salvano MA, Oliver G (2007) Physical adsorption of aflatoxin B1 by lactic acid bacteria and saccharomyces cerevisiae: a theoretical model. J Food Prot 70(9):2148–2154

Wu F, Munkvold GP (2008) Mycotoxins in ethanol co-products: modeling economic impacts on the livestock industry and management strategies. J Agric Food Chem 56:3900–3911

Murthy GS, Townsend DE, Meerdink GL, Bargren GL, Tumbleson ME, Singh V (2005) Effect of aflatoxin B1 on dry-grind ethanol process. Cereal Chem 82(3):302–304

Kłosowski G, Mikulski D, Grajewski J, Błajet-Kosicka A (2010) The influence of raw material contamination with mycotoxins on alcoholic fermentation indicators. Biores Technol 101:3142–3152

Acknowledgements

This research was supported in part by Research Funds of the Dokuz Eylül University by a grant number of 2021.KB.FEN.044.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Funding

Dokuz Eylül Üniversitesi,2021.KB.FEN.044,serpil ozmihci

Conflict of interest

The authors declare no competing interests could have influenced the work reported in this study.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Özmıhçı, S., Hacıoğlu, İ. & Altındağ, E.E. Impacts of mycotoxin on biohydrogen production from waste dry fruits. J Mater Cycles Waste Manag 24, 1736–1746 (2022). https://doi.org/10.1007/s10163-022-01418-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10163-022-01418-5