Abstract

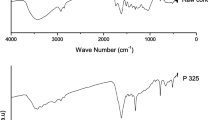

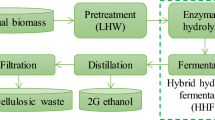

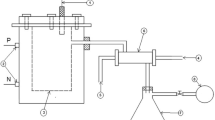

In this work, the trunk and flower stalk of henequen were characterized and subjected to pyrolysis at high temperatures. The chemical composition of henequen biomass is very similar to other agricultural waste, namely 49–59% holocellulose and 23–28% lignin. The yields of pyrolysis products depend on the conditions used, and the maximum yields obtained were 40% bio-oil, 27% biochar, and 46% gas. The solid (biochar) and liquid (bio-oil) products obtained were characterized by elemental analysis and gas chromatography coupled to a mass detector, respectively. It was determined that bio-oil consists of aromatic compounds, linear hydrocarbons, and phenolic derivatives, which are present either in the biomass or are produced during thermal degradation of the lignocellulosic components. The elemental carbon content of biochar increases by 65% in comparison with the lignocellulosic biomass before pyrolysis and the highest heating value (24,031 kJ/kg) was obtained for carbon produced at higher temperatures.

Similar content being viewed by others

References

Panepinto D, Viggiano F, Genon G (2015) Analysis of the environmental impact of a biomass plant for the production of bioenergy. Renew Sustain Energy Rev 51:634–647. https://doi.org/10.1016/j.rser.2015.06.048

Andrade LA, Barrozo MAS, Vieira LGM (2016) Thermo-chemical behavior and product formation during pyrolysis of mango seed Shell. Ind Crop Prod 85:174–180. https://doi.org/10.1016/j.indcrop.2016.03.004

Ko S, Lautala P, Handler RM (2018) Securing the feedstock procurement for bioenergy products: a literature review on the biomass transportation and logistics. J Clean Prod 200:205–218. https://doi.org/10.1016/j.jclepro.2018.07.241

Surendra KC, Ogoshi R, Zaleski HM, Hashimoto AG, Khanal SK (2018) High yielding tropical energy crops for bioenergy production: effects of plant components, harvest years and locations on biomass composition. Bioresour Technol 251:218–229. https://doi.org/10.1016/j.biortech.2017.12.044

Ba Y, Liu F, Wang X, Yang J (2020) Pyrolysis of C3 energy plant (arundo donax): thermogravimetry, mechanism, and potential evaluation. Ind Crop Prod 149:112337. https://doi.org/10.1016/j.indcrop.2020.112337

Lazaro CZ, Bosio M, Ferreira J, Varesche M, Silva E (2015) The biological hydrogen production potential of agroindustrial residues. Waste Biomass Valoriz 6:273–280. https://doi.org/10.1007/s12649-015-9353-8

Nanda S, Azargohar R, Dalai AK, Kozinski JA (2015) An assessment on the sustainability of lignocellulosic biomass for biorefining. Renew Sustain Energy Rev 50:925–941. https://doi.org/10.1016/j.rser.2015.05.058

Loh SK (2017) The potential of the Malaysian oil palm biomass as a renewable energy source. Energy Convers Manag 141:285–298. https://doi.org/10.1016/j.enconman.2016.08.081

Corneli E, Dragoni F, Adessi A, De Philippis R, Bonari E, Ragaglini G (2016) Energy conversion of biomass crops and agroindustrial residues by combined hydrogen/biomethane system and anaerobic digestion. Bioresour Technol 211:509–518. https://doi.org/10.1016/j.biortech.2016.03.134

Gómez N, Banks SW, Nowakowski DJ, Rosas JG, Sánchez ME, Bridgwater AV (2018) Effect of temperature on product performance of a high ash biomass during fast pyrolysis and its bio-oil storage evaluation. Fuel Process Techol 172:97–105. https://doi.org/10.1016/j.fuproc.2017.11.021

Song X, Yang Y, Xhang M, Zhang K, Wang D (2018) Ultrasonic pelleting of torrefied lignocellulosic biomass for bioenergy production. Renew Energy 129:56–62. https://doi.org/10.1016/j.renene.2018.05.084

Mussgnug JH, Thomas-Hall S, Rupprecht J, Foo A, Klassen V, McDowall A, Schenk PM, Kruse O, Hankamer B (2017) Engineering photosynthetic light capture: impacts on improved solar energy to biomass conversion. Plant Biotechnol J 5:802–814. https://doi.org/10.1111/j.1467-7652.2007.00285.x

Thangavelu SK, Ahmed AS, Ani FN (2016) Review on bioethanol as alternative fuel for spark ignition engines. Renew Sustain Energy Rev 56:820–835. https://doi.org/10.1016/j.rser.2015.11.089

Tauro R, Serrano-Medrano M, Masera O (2018) Solid biofuels in Mexico: a sustainable alternative to satisfy the increasing demand for heat and power. Clean Technol Environ Policy 20:1527–1539. https://doi.org/10.1007/s10098-018-1529-z

Briones-Hidrovo A, Copa J, Tarelho LAC, Gonçalves C, Pacheco T, da Costa T, Dias AC (2021) Environmental and energy performance of residual forest biomass for electricity generation: gasification vs. combustion. J Clean Product 289:125680. https://doi.org/10.1016/j.jclepro.2020.125680

Farías JC, Velázquez U, Vargas A, Pineda MG, Mendoza EA, Rutiaga JG, Saucedo J, Castro AJ (2016) Production of fermentable sugars and hydrogen-rich gas from agave tequilana biomass. Bioenerg Res 9:1015–1022. https://doi.org/10.1007/s12155-016-9799-y

Fonseca-Prieto FV, Canché-Escamilla G, Chavarria-Hernández JC, Duarte-Aranda S (2014) Characterization of lignocellulosic residues of henequen and their use as a bio-oil source. Biomass Convers Biorefin 4:95–104. https://doi.org/10.1007/s13399-013-0099-x

Demir M, Tessema TD, Farghaly AA, Nyankson E, Saraswat SK, Aksoy B, Islamoglu T, Collinson MM, El-Kaderi HM, Gupta RB (2018) Lignin-derived heteroatom-doped porous carbons for supercapacitor and CO2 capture applications. Int J Energy Res 42:2686–2700. https://doi.org/10.1002/er.4058

Chen D, Chen X, Sun J, Zheng Z, Fu K (2016) Pyrolysis polygeneration of pine nut shell: Quality of pyrolysis products and study on the preparation of activated carbon from biochar. Bioresour Technol 216:629–636. https://doi.org/10.1016/j.rser.2014.07.107

Rodier L, Bilba K, Onésippe C, Arsène MA (2019) Utilization of bio-chars from sugarcane bagasse pyrolysis in cement-based composites. Ind Crop Prod 1411:111731. https://doi.org/10.1016/j.indcrop.2019.111731

Özcimen D, Ersoy-Meriçboyu A (2010) Characterization of biochar and bio-oil samples obtained from carbonization of various biomass materials. Renewable Energy 35:1319–1324. https://doi.org/10.1016/j.renene.2009.11.042

Titiladunayo IF, McDonald AG, Fapetu OP (2012) Effect of temperature on biochar product yield from selected lignocellulosic biomass in a pyrolysis process. Waste Biomass Valoriz 3:311–318. https://doi.org/10.1007/s12649-012-9118-6

Kim KH, Him TS, Lee SM, Choi D, Yeo H, Choi IG, Choi JW (2012) Comparison of physicochemical features of biooils and biochars produced from various woody biomasses by fast pyrolysis. Renewable Energy 50:188–195. https://doi.org/10.1016/j.renene.2012.06.030

Nanda S, Azargohar R, Kozinski JA, Dalai AK (2014) Characteristic studies on the pyrolysis products from hydrolyzed canadian lignocellulosic feedstocks. Bioenergy Resour 7:174–191. https://doi.org/10.1007/s12155-013-9359-7

Tekin K, Karagöz S, Bektaş S (2014) A review of hydrothermal biomass processing. Renew Sustain Energy Rev 40:673–768. https://doi.org/10.1016/j.rser.2014.07.216

Altinci OC, Demir M (2020) Beyond conventional activating methods, a green approach for the synthesis of biocarbon and its supercapacitor electrode. Energy Fuels 34:7658–7665. https://doi.org/10.3390/su11020414

Tinaut FV, Melgar A, Pérez JF, Horrillo A (2008) Effect of biomass particle size and air superficial velocity on the gasification process in a downdraft fixed bed gasifier. an experimental and modelling study. Fuel Process Technol 89:1076–1089. https://doi.org/10.1016/j.fuproc.2008.04.010

Puig-Arnavat M, Thomsen TP, Ravenni G, Clausen LR, Sárossy Z, Ahrenfeldt J (2019) Pyrolysis and gasification of lignocellulosic biomass. In: Bastidas-Oyanedel JR, Schmidt J (eds) Biorefinery. Springer International Publishing, Cham. https://doi.org/10.1007/978-3-030-10961-5

Jung SJ, Kim SH, Chung IM (2015) Comparison of lignin, cellulose, and hemicellulose contents for biofuels utilization among 4 types of lignocellulosic crops. Biomass Bioenerg 83:322–327. https://doi.org/10.1016/j.ecolind.2014.06.043

Kung CC, Wong F, Choi Y (2015) Pyrolysis and biochar potential using crop residues and agricultural wastes in China. Ecol Indic 51:139–145. https://doi.org/10.1016/j.energy.2017.11.062

Yang L, Lu M, Carl S, Mayer JA, Cushman JC, Tian E, Lin H (2015) Biomass characterization of Agave and Opuntia as potential biofuel feedstocks. Biomass Bioenerg 76:43–53. https://doi.org/10.1016/j.biombioe.2015.03.004

Zhang J, Liu J, Liu R (2015) Effects of pyrolysis temperature and heating time on biochar obtained from the pyrolysis of straw and lignosulfonate. Bioresour Technol 176:288–291. https://doi.org/10.1016/j.biortech.2014.11.011

Lazzari E, Schena T, Orimaz CT, Maciel GP, Machado ME, Cardoso CA, Jacques RA, Caramao EB (2015) Production and chromatographic characterization of bio-oil from the pyrolysis of mango seed waste. Ind Crop Prod 83:529–536. https://doi.org/10.1016/j.indcrop.2015.12.073

Pérez-Pimienta JA, García-López RM, Mendez-Acosta HM, González-Alvarez V, Simmons BA, Mendoza-Pérez JA, Arreola-Vargas J (2021) Ionic liquid-water mixtures enhance pretreatment and anaerobic digestion of agave bagasse. Ind Crop Prod 171:113924. https://doi.org/10.1016/j.indcrop.2021.113924

Gómez-Guerrero A, Valdez-Vazquez I, Caballero-Caballero M, Chiñas-Castillo F, Alavéz-Ramírez R, Montes-Bernabé J (2019) Co-digestion of Agave angustifolia Haw bagasse and vinasses for biogas production from mescal industry. Rev Mex Ing Quím 18:1073–1083. https://doi.org/10.24275/uam/izt/dcbi/revmexingquim/2019v18n3/Gomez

Motghare KA, Rathod AP, Wasewar KL, Labhsetwar NK (2016) Comparative study of different waste biomass for energy application. Waste Manag 47:40–45. https://doi.org/10.1016/j.wasman.2015.07.032

Wang S, Dai G, Yang H, Luo Z (2017) Lignocellulosic biomass pyrolysis mechanism: a state-of-the-art review. Prog Energy Combust Sci 62:33–86. https://doi.org/10.1016/j.pecs.2017.05.004

Munir S, Daood SS, Nimmo W, Cunlife AM, Gibbs BM (2009) Thermal analysis and devolatilization kinetics of cotton stalk, sugar cane bagasse and shea meal under nitrogen and air atmospheres. Bioresour Technol 100:1413–1418. https://doi.org/10.1016/j.biortech.2008.07.065

Stefanidis SD, Kalogiannis KG, Iliopoulou EF, Micahilof CM, Pilavachi PA, Lappas AA (2014) A study of lignocellulosic biomass pyrolysis via the pyrolysis cellulose, hemicellulose and lignin. J Anal Appl Pyrolisis 105:143–150. https://doi.org/10.1016/j.jaap.2013.10.013

Wang K, Kim KH, Brown RC (2014) Catalytic pyrolysis of individual components of lignocellulosic biomass. Green Chem 16:727–725. https://doi.org/10.1039/c3gc41288a

Valle B, Remiro A, García-Gómez N, Gayubo AG, Bilbao J (2019) Recent research progress on bio-oil conversion into bio-fuels and raw chemicals: a review. J Chem Technol Biotechnol 94:670–689. https://doi.org/10.1002/jctb.5758

Sahoo K, Kumar A, Chakraborty JP (2021) A comparative study on valuable products: bio-oil, biochar, non-condensable gases from pyrolysis of agricultural residues. J Mat Cycles Waste Manag 23:186–204. https://doi.org/10.1007/s10163-020-01114-2

Acknowledgements

To the Sectorial Fund Conacyt-Sener Sustainability for its economic support granted for the project Use of woody biomass as a solid biofuel for the generation of electric energy in rural areas with code 249581. We thank José M.Baas-López for the elemental analyses of bio-oil and biochar.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Canché-Escamilla, G., Guin-Aguillón, L., Duarte-Aranda, S. et al. Characterization of bio-oil and biochar obtained by pyrolysis at high temperatures from the lignocellulosic biomass of the henequen plant. J Mater Cycles Waste Manag 24, 751–762 (2022). https://doi.org/10.1007/s10163-022-01361-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10163-022-01361-5