Abstract

Dwindling fossil fuels, and the rise in energy demand have urged us to explore alternative renewable energy forms. An integrated process of dark fermentation and microalgal cultivation to deliver biofuels are gaining momentum in recent times. In this study, in the first stage, the starchy wastewater (SWW) with poultry manure (PM) was treated to produce a maximum hydrogen yield of 4.11 mol H2/Kg COD reduced to 5.03 mol H2/Kg COD reduced. The reutilization of soluble spent wash for the cultivation of Chlamydomonas reinhardtii yielded a biomass concentration of 1.45–1.02 g/L. The potentiality of algae to produce biodiesel was checked effectively, and it was reported that a biodiesel of 90.34 g/Kg Algal Biomass to 119.61 g/Kg Algal was yielded. The integration of the process enhanced the overall energy with an efficient removal of organic content. In conclusion, the valorisation of PM with SWW through dark fermentation and microalgal cultivation will open avenues to generate sustainable bioenergy forms.

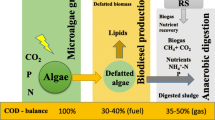

Graphic abstract

Similar content being viewed by others

Abbreviations

- COD:

-

Chemical oxygen demand

- PM:

-

Poultry manure

- SWW:

-

Starchy wastewater

- TDS:

-

Total dissolved solids

- TS:

-

Total solids

- TKN:

-

Total kjeldahl nitrogen

- TSS:

-

Total suspended solids

- TVS:

-

Total volatile solids

- VSS:

-

Volatile suspended solids

- VDS:

-

Volatile dissolved solids

References

Banerjee, S., Banerjee, S., Ghosh, A. K., & Das, D. Maneuvering the genetic and metabolic pathway for improving biofuel production in algae: Present status and future prospective. Renew Sustain Energy Rev, 133 (2020). https://doi.org/https://doi.org/10.1016/j.rser.2020.110155.

Das D, Veziroǧlu TN (2001) Hydrogen production by biological processes: a survey of literature. Int J Hydrog Energy 26:13–28

Rafieenia R, Lavagnolo MC, Pivato A (2018) Pre-treatment technologies for dark fermentative hydrogen production: current advances and future directions. J Waste Manag 71:734–748

Wadjeam P, Reungsang A, Imai T, Plangklang P (2019) Co-digestion of cassava starch wastewater with buffalo dung for bio-hydrogen production. Int J Hydrog Energy. https://doi.org/10.1016/j.ijhydene.2019.04.138

Wei J, Liu ZT, Zhang X (2010) Biohydrogen production from starch wastewater and application in fuel cell. Int J Hydrog Energy 35:2949–2952

Lin CY, Lay CH (2004) Carbon/nitrogen-ratio effect on fermentative hydrogen production by mixed microflora. Int J Hydrog Energy 29:41–45

Ahn, Y., Lee, W., Kang, S., Kim, S.H.: Enhancement of Sewage Sludge Digestion by Co-digestion with Food Waste and Swine Waste. Waste Biomass Valorization. 1–10 (2019). doi:https://doi.org/10.1007/s12649-018-00558

Kulcu R (2016) New kinetic modelling parameters for composting process. J Mater Cycles Waste Manag 18(4):734–741

Kawata K, Nissato K, Shiota N, Hori T, Asada T, Oikawa K (2006) Variation in pesticide concentrations during composting of food waste and fowl droppings. Bull Environ Contam Toxicol 77:391–398

Demirel B, Göl NP, Onay TT (2013) Evaluation of heavy metal content in digestate from batch anaerobic co-digestion of sunflower hulls and poultry manure. J Mater Cycles Waste Manag 15(2):242–246

Lo YC, Chen CY, Lee CM, Chang JS (2011) Photo fermentative hydrogen production using dominant components (acetate, lactate, and butyrate) in dark fermentation effluents. Int J Hydrog Energy 36:14059–14068

Sun C, Hao P, Qin B, Wang B, Di X, Li Y (2016) Co-production of hydrogen and methane from herbal medicine wastewater by a combined UASB system with immobilized sludge (H2 production) and UASB system with suspended sludge (CH4 production). Water Sci Technol 73:130–136

Schievano A, Sciarria TP, Gao YC, Scaglia B, Salati S, Zanardo M, Quiao W, Dong R, Adani F (2016) Dark fermentation, anaerobic digestion and microbial fuel cells: an integrated system to valorize swine manure and rice bran. J Waste Manag 56:519–529

Mishra P, Balachandar G, Das D (2017) Improvement in biohythane production using organic solid waste and distillery effluent. J Waste Manag 66:70–78

Varanasi JL, Kumari S, Das D (2018) Improvement of energy recovery from water hyacinth by using integrated system. Int J Hydrog Energy 43:1303–1318

Hassan GK, Hemdan BA, El-Gohary FA (2020) Utilization of food waste for bio-hydrogen and bio-methane production: influences of temperature, OLR, and in situ aeration. J Mater Cycles Waste Manag 22:1218–1226

Rani DS, Thirumale S, Nand K (2003) Methane generation from corncobs treated with xylanolytic consortia. J Mater Cycles Waste Manag 5(2):125–129

Van der Hoek J, Duijff R, Reinstra O (2018) Nitrogen recovery from wastewater: Possibilities, competition with other resources, and adaptation pathways. Sustainability 10:4605

Kumari S, Das D (2017) Improvement of biohydrogen production using acidogenic culture. Int J Hydrog Energy 42:4083–4094

Gorman DS, Levine RP (1965) Cytochrome f and plastocyanin: their sequence in the photosynthetic electron transport chain of Chlamydomonas reinhardtii. Proc Natl Acad Sci U S A 54:1665–1669

Ghosh, S., Roy, S., Das, D.: Enhancement in lipid content of Chlorella sp. MJ 11/11 from the spent medium of thermophilic biohydrogen production process. Bioresour. Technol. 223, 219–226 (2017)

Bligh EG, Dyer WJ (1959) A rapid method of total lipid extraction and purification. Can J Biochem Physiol 37:911–917

Banerjee S, Singh H, Das D, Atta A (2019) Process optimization for enhanced biodiesel production by Neochloris oleoabundans UTEX 1185 with concomitant CO2 sequestration. IndEngChem Res. https://doi.org/10.1021/acs.iecr.8b05730

Amin S (2009) Review on biofuel oil and gas production processes from microalgae. Energ Convers Manage 50:1834–1840

Wan J, Gu J, Zhao Q, Liu Y (2016) COD capture: a feasible option towards energy self-sufficient domestic wastewater treatment. Sci Rep 6:25054

Dubois M, Gilles KA, Hamilton JK, Rebers PT, Smith F (1956) Colorimetric method for determination of sugars and related substances. Anal Chem 28:350–356

Lowry OH, Rosebrough NJ, Farr AL, Randall RJ (1951) Protein measurement with the Folin phenol reagent. J Biol Chem 193:265–275

American Public Health Association, A. P. H. A.: Standard methods for the examination of water and wastewater. 21 (1995)

Nicholas DD, Nason A (1957) Determination of nitrate and nitrite. Methods Enzymol 3:981–984

Herbert D, Phipps PJ, Strange RE (1971) Chapter III chemical analysis of microbial cells. J Microbiol Methods 5:209–344

Ma, T., Zuazaga, G.: Micro-Kjeldahl determination of nitrogen. A new indicator and an improved rapid method. Ind. Eng. Chem., Anal. Ed.14, 280–282 (1942)

Guo WQ, Ren NQ, Chen ZB, Liu BF, Wang XJ, Xiang WS, Ding J (2008) Simultaneous biohydrogen production and starch wastewater treatment in an acidogenic expanded granular sludge bed reactor by mixed culture for long-term operation. Int J Hydrog Energy 33:7397–7404

Salerno MB, Park W, Zuo Y, Logan BE (2006) Inhibition of biohydrogen production by ammonia. Water Res 40:1167–1172

Mo Y, Jensen KF (2016) A miniature CSTR cascade for continuous flow of reactions containing solids. Reaction Chemistry & Engineering 1(5):501–507

Lee MJ, Zhang S, Cho YB, Park JE, Chang KH, Hwang SJ (2015) Effects of nitrate concentration on biohydrogen production and substrate utilization in dark-fermentation. J Mater Cycles Waste Manag 17(1):27–32

Cao X, Zhao Y (2009) The influence of sodium on biohydrogen production from food waste by anaerobic fermentation. J Mater Cycles Waste Manag 11(3):244–250

Mohan SV, Devi MP (2012) Fatty acid rich effluent from acidogenic biohydrogen reactor as substrate for lipid accumulation in heterotrophic microalgae with simultaneous treatment. Bioresour Technol 123:627–635

Ren HY, Liu BF, Kong F, Zhao L, Ren N (2015) Hydrogen and lipid production from starch wastewater by co-culture of anaerobic sludge and oleaginous microalgae with simultaneous COD, nitrogen and phosphorus removal. Water Res 85:404–412

Wang, J., Yin, Y.: Biohydrogen production from organic wastes. Springer (2017)

Yokoi H, Tokushige T, Hirose J, Hayashi S, Takasaki Y (1998) H2 production from starch by a mixed culture of Clostridium butyricum and Enterobacteraerogenes. Biotechnol Lett 20:143–147

Panyaping K, Moontee P (2018) Potential of biogas production from mixed leaf and food waste in anaerobic reactors. J Mater Cycles Waste Manag 20(2):723–737

Gong, Y., Lyu, Y., Li, P., Gong, D., Gao, Z., Chen, J., ... & Tian, Y.: Characterization of anaerobic digestion of Chinese cabbage waste by a thermophilic microorganism community. J. Mater. Cycles Waste Manag. 21(5), 1144–1154 (2019)

Kim JR, Kim JY (2016) Feasibility assessment of thermophilic anaerobic digestion process of food waste. J Mater Cycles Waste Manag 18(3):413–418

Moon M, Kim CW, Park WK, Yoo G, Choi YE, Yang JW (2013) Mixotrophic growth with acetate or volatile fatty acids maximizes growth and lipid production in Chlamydomonas reinhardtii. Algal Res 2:352–357

Lin, X., Xiong, L., Qi, G., Shi, S., Huang, C., Chen,X.: Using butanol fermentation wastewater for bio-butanol production after removal of inhibitory compounds by micro-mesoporous hyper cross linked polymeric adsorbent.ACS Sustain Chem Eng. 3, 702–709 (2015)

Park GW, Fei Q, Jung K, Chang HN, Kim YC, Kim NJ, Choi JDR, Kim S, Cho J (2014) Volatile fatty acids derived from waste organics provide an economical carbon source for microbial lipids/biodiesel production. Biotechnol J 9:1536–1546

Cheah WY, Show PL, Chang JS, Ling TC, Juan JC (2015) Biosequestration of atmospheric CO2 and flue gas-containing CO2 by microalgae. Bioresour Technol 184:190–201

Nguyen MLT, Lin CY, Lay CH (2019) Microalgae cultivation using biogas and digestate carbon sources. Biomass Bioenerg 122:426–432

Prandini JM, Da Silva MLB, Mezzari MP, Pirolli M, Michelon W, Soares HM (2016) Enhancement of nutrient removal from swine wastewater digestate coupled to biogas purification by microalgae Scenedesmus spp. Bioresour Technol 202:67–75

Tan X, Chu H, Zhang Y, Yang L, Zhao F, Zhou X (2014) Chlorella pyrenoidosa cultivation using anaerobic digested starch processing wastewater in an airlift circulation photobioreactor. Bioresour Technol 170:538–548

Franchino M, Comino E, Bona F, Riggio VA (2013) Growth of three microalgae strains and nutrient removal from an agro-zootechnical digestate. Chemosphere 92(6):738–744

Liu CH, Chang CY, Liao Q, Zhu X, Liao CF, Chang JS (2013) Biohydrogen production by a novel integration of dark fermentation and mixotrophic microalgae cultivation. Int J Hydrog Energy 38:15807–15814

Chalima A, Hatzidaki A, Karnaouri A, Topakas E (2019) Integration of a dark fermentation effluent in a microalgal-based biorefinery for the production of high-added value omega-3 fatty acids. Appl Energy 241:130–138

Turon V, Trably E, Fayet A, Fouilland E, Steyer JP (2015) Raw dark fermentation effluent to support heterotrophic microalgae growth: microalgae successfully outcompete bacteria for acetate. Algal Res 12:119–125

Banerjee S, Rout S, Banerjee S, Atta A, Das D (2019) Fe2O3 nanocatalyst aided transesterification for biodiesel production from lipid-intact wet microalgal biomass: A biorefinery approach. Energ Convers Manage 195:844–853

Stewart, V.A.L.L.E.Y.: Nitrate respiration in relation to facultative metabolism in enterobacteria. Microbiol. Rev. 52, 190 (1988)

Lauver L, Baker LA (2000) Mass balance for wastewater nitrogen in the central Arizona-Phoenix ecosystem. Water Res 34:2754–2760

Jia H, Yuan Q (2016) Removal of nitrogen from wastewater using microalgae and microalgae–bacteria consortia. Cogent Environ Sci 2:1275089

Zimmo OR, Van der Steen NP, Gijzen HJ (2003) Comparison of ammonia volatilisation rates in algae and duckweed-based waste stabilisation ponds treating domestic wastewater. Water Res 37:4587–4594

Sheets JP, Yang L, Ge X, Wang Z, Li Y (2015) Beyond land application: Emerging technologies for the treatment and reuse of anaerobically digested agricultural and food waste. J Waste Manag 44:94–115

Kalyuzhnyi S, Sklyar V, Fedorovich V, Kovalev A, Nozhevnikova A, Klapwijk A (1999) The development of biological methods for utilisation and treatment of diluted manure streams. Water Sci Technol 40:223–229

Mishra P, Roy S, Das D (2015) Comparative evaluation of the hydrogen production by mixed consortium, synthetic co-culture and pure culture using distillery effluent. Bioresour Technol 198:593–602

Kumari S, Das D (2015) Improvement of gaseous energy recovery from sugarcane bagasse by dark fermentation followed by biomethanation process. Bioresour Technol 194:354–363

Cheng J, Xie B, Zhou J, Song W, Cen K (2010) Cogeneration of H2 and CH4 from water hyacinth by two-step anaerobic fermentation. Int J Hydrog Energy 35(7):3029–3035

Acknowledgements

The authors gratefully acknowledge Department of Biotechnology, India and Ministry of New and Renewable Energy, India for necessary financial support and also to Indian Institute of Technology Kharagpur for the facilities provided to conduct this research work.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Statement of novelty: Increase in environmental pollution at an alarming rate along with significant aggravation of global energy demand is a major concern for ecological sustenance. Contextually, production of renewable biofuel by concomitant waste remediation is a sustainable approach to satiate this energy requirement. Several authors have reported that wastewater treatment by microalgal cultivation coupled with biofuel production is an efficient method for addressing the dual problem of waste management and fuel crisis. In the present study, integrated process of dark fermentation for biohydrogen production followed by phycoremediation is the primary focus. In the first stage biohydrogen was produced by dark fermentation using starchy wastewater and poultry manure as a co-substrate. And in the second stage, bioremediation of the organic content in the spent wash was achieved by cultivating Chlamydomonas reinhardtii in it; followed by the subsequent utilization of the microalgal biomass for biodiesel production. The novelty of the present study lies on the two-stage process of dark fermentation followed by algal production for the dual purpose of organic waste treatment and biofuel production, thereby enhancing the overall sustainability of the process.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Radhakrishnan, R., Banerjee, S., Banerjee, S. et al. Sustainable approach for the treatment of poultry manure and starchy wastewater by integrating dark fermentation and microalgal cultivation. J Mater Cycles Waste Manag 23, 790–803 (2021). https://doi.org/10.1007/s10163-021-01173-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10163-021-01173-z