Abstract

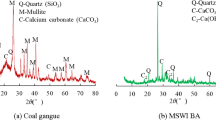

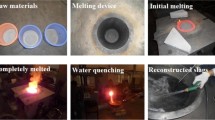

In this study, two types of municipal solid waste incineration (MSWI) bottom ash (BA) (MSWI-BA-A, water quenched, MSWI-BA-B, natural cooling), are utilized as alternative materials for clinker sintering. Fixed clinker modulus (lime saturation ratio = 0.90 ± 0.01, silica modulus = 2.6 ± 0.1 and alumina modulus = 1.5 ± 0.1), designed gradient addition ratio of MSWIBA (0, 3%, 6%, 9% and 12%) and same sintering temperature (1723.15 K) are adopted to conduct the experiments. Raw materials are characterized by XRF, X-ray diffraction and differential thermal analysis. Clinkers are analyzed and evaluated by XRF, X-ray diffraction, petrographic analysis, compressive and flexural strength tests and toxicity characteristic leaching procedure. The major difference of the two types of MSWIBA is LOI value which is supposed to be the most probable reason for huge difference between liquid phase formation temperature variation and incremental introduction of MSWI. MSWI-BA-A increases liquid phase formation temperature. Liquid phase formation temperatures and MSWI-BA-B samples addition ratios nearly present negative linear correlation. All clinkers sintered with addition of MSWIBA slightly reduce water demand for normal consistency. MSWIBA addition poses relatively obvious influence on initial setting time and little effect on final setting time. There is an increase in initial strength and a decrease in 28-day strength of clinkers sintered with MSWIBA, 28-day compressive strength decreases with the incremental introduction of MSWIBA. Distinct characteristics, such as free lime, periclase, orthorhombic tricalcium aluminate (C3A) crystal and secondary Belite crystal, are observed by petrographic analysis. MSWIBA is significant source of free lime and periclase in clinkers. Incremental input of alkali introduced by MSWIBA influences clinker sintering and mineral crystallinzation, further results in orthorhombic C3A crystal and indistinct Alite edge caused by corrosion. Leaching concentration of heavy metals from mortars prepared with the sintering clinkers is lower than corresponding concentration of the Chinese National Standard GB 30760-2014.

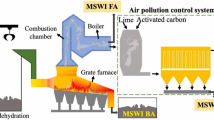

Graphic abstract

Similar content being viewed by others

References

Yang Z, Ji R, Liu L, Wang X, Zhang Z (2018) Recycling of municipal solid waste incineration by-product for cement composites preparation. Constr Build Mater 162:794–801

Wang F-H, Zhang F, Chen Y-J, Gao J, Zhao B (2015) A comparative study on the heavy metal solidification/stabilization performance of four chemical solidifying agents in municipal solid waste incineration fly ash. J Hazard Mater 300:451–458

Yao J, Li W-B, Kong Q-N, Wu Y-Y, He R, Shen D-S (2010) Content, mobility and transfer behavior of heavy metals in MSWI bottom ash in Zhejiang province, China. Fuel 89:616–622

Liu G, Hao Y, Dong L, Yang Z, Zhang Y, Ulgiati S (2017) An emergy-LCA analysis of municipal solid waste management. Resour Conserv Recycl 120:131–143

Hsieh C-H, Shih K, Hu C-Y, Lo S-L, Li N-H, Cheng Y-T (2013) The effects of salinity and temperature on phase transformation of copper-laden sludge. J Hazard Mater 244:501–506

Choy KKH, Ko DCK, Cheung WH, Fung JSC, Hui DCW, Porter JF, McKay G (2004) Municipal solid waste utilization for integrated cement processing with waste minimization: a pilot scale proposal. Process Saf Environ 82:200–207

Hartmann S, Koval L, Škrobánková H, Matýsek D, Winter F, Purgar A (2015) Possibilities of municipal solid waste incinerator fly ash utilisation. Waste Manag Res 33:740–747

Yang Z, Tian S, Liu L, Wang X, Zhang Z (2018) Recycling ground MSWI bottom ash in cement composites: long-term environmental impacts. Waste Manag 78:841–848

Siddique R (2010) Utilization of municipal solid waste (MSW) ash in cement and mortar. Resour Conserv Recycl 54:1037–1047

Korai MS, Ali M, Lei C, Mahar RB, Yue D (2020) Comparison of MSW management practices in Pakistan and China. J Mater Cycles Waste Manag 22:443–453

Lu J-W, Zhang S, Hai J, Lei M (2017) Status and perspectives of municipal solid waste incineration in China: a comparison with developed regions. Waste Manag 69:170–186

Yin K, Dou X, Chan W-P, Chang VW-C (2020) Comparative leaching characteristics of fly/bottom ashes from municipal solid waste incineration under various environmental stresses. J Mater Cycles Waste Manag 22:46–55

Liu Y, Zheng L, Li X, Xie S (2009) SEM/EDS and XRD characterization of raw and washed MSWI fly ash sintered at different temperatures. J Hazard Mater 162:161–173

Polettini A, Pomi R, Sirini P, Testa F (2001) Properties of Portland cement—stabilised MSWI fly ashes. J Hazard Mater 88:123–138

Andreola F, Barbieri L, Hreglich S, Lancellotti I, Morselli L, Passarini F, Vassura I (2008) Reuse of incinerator bottom and fly ashes to obtain glassy materials. J Hazard Mater 153:1270–1274

Dou X, Ren F, Nguyen MQ, Ahamed A, Yin K, Chan WP, Chang VW-C (2017) Review of MSWI bottom ash utilization from perspectives of collective characterization, treatment and existing application. Renew Sust Energ Rev 79:24–38

Margallo M, Taddei MBM, Hernández-Pellón A, Aldaco R, Irabien A (2015) Environmental sustainability assessment of the management of municipal solid waste incineration residues: a review of the current situation. Clean Technol Environ Policy 17:1333–1353

Yin K, Ahamed A, Lisak G (2018) Environmental perspectives of recycling various combustion ashes in cement production–A review. Waste Manag 78:401–416

Kurashima K, Kumagai S, Kameda T, Saito Y, Yoshioka T (2020) Heavy metal removal from municipal solid waste fly ash through chloride volatilization using poly(vinyl chloride) as chlorinating agent. J Mater Cycles Waste Manag. https://doi.org/10.1007/s10163-020-01021-6

Li X-G, Lv Y, Ma B-G, Chen Q-B, Yin X-B, Jian S-W (2012) Utilization of municipal solid waste incineration bottom ash in blended cement. J Clean Prod 32:96–100

Bertolini L, Carsana M, Cassago D, Curzio AQ, Collepardi M (2004) MSWI ashes as mineral additions in concrete. Cem Concr Res 34:1899–1906

Weng M-C, Lin C-L, Ho C-I (2010) Mechanical properties of incineration bottom ash: the influence of composite species. Waste Manag 30:1303–1309

Li Y, Hao L, Chen X (2016) Analysis of MSWI bottom ash reused as alternative material for cement production. Proc Environ Sci 31:549–553

Shih P-H, Chang J-E, Chiang L-C (2003) Replacement of raw mix in cement production by municipal solid waste incineration ash. Cem Concr Res 33:1831–1836

Aranda Usón A, López-Sabirón AM, Ferreira G, Llera Sastresa E (2013) Uses of alternative fuels and raw materials in the cement industry as sustainable waste management options. Renew Sust Energ Rev 23:242–260

Kikuchi R (2001) Recycling of municipal solid waste for cement production: pilot-scale test for transforming incineration ash of solid waste into cement clinker. Resour Conserv Recycl 31:137–147

Lam CHK, Barford JP, McKay G (2010) Utilization of incineration waste ash residues as Portland cement clinker. Chem Eng Trans 21:757–762

Luo L, Zhang Y, Bao S, Chen T (2016) Utilization of iron ore tailings as raw material for Portland cement clinker production. Adv Mater Sci Eng 1–6

Li H, Huang Y, Yang X, Jiang Z, Yang Z (2018) Approach to the management of magnesium slag via the production of Portland cement clinker. J Mater Cycles Waste Manag 20:1701–1709

Pan JR, Huang C, Kuo J-J, Lin S-H (2008) Recycling MSWI bottom and fly ash as raw materials for Portland cement. Waste Manag 28:1113–1118

Saikia N, Cornelis G, Mertens G, Elsen J, Van Balen K, Van Gerven T, Vandecasteele C (2008) Assessment of Pb-slag, MSWI bottom ash and boiler and fly ash for using as a fine aggregate in cement mortar. J Hazard Mater 154:766–777

Wu B, Wang D, Chai X, Takahashi F, Shimaoka T (2016) Characterization of chlorine and heavy metals for the potential recycling of bottom ash from municipal solid waste incinerators as cement additives. Front Environ Sci Eng 10:9

Funari V, Braga R, Bokhari SNH, Dinelli E, Meisel T (2015) Solid residues from Italian municipal solid waste incinerators: a source for “critical” raw materials. Waste Manag 45:206–216

Wang L, Jin Y, Nie Y, Li R (2010) Recycling of municipal solid waste incineration fly ash for ordinary Portland cement production: a real-scale test. Resour Conserv Recycl 54:1428–1435

Nabih K, Barbacha R, De La Torre AG, Sassi O, Kada K, Cherkaoui El-Moursli F (2014) Effect of substitution of lime stone in CPJ45 by Jorf Lasfer fly and bottom ash on the hydration of cement and on the mechanical proprieties of mortar. In: International congress on materials and structural stability, CMSS 2013, EDP Sciences, Rabat

Tsakiridis PE, Samouhos M, Peppas A, Katsiotis NS, Velissariou D, Katsiotis MS, Beazi M (2016) Silico-aluminous bottom ash valorisation in cement clinker production: synthesis, characterization and hydration properties. Constr Build Mater 126:673–681

Li H, Xu W, Yang X, Wu J (2014) Preparation of Portland cement with sugar filter mud as lime-based raw material. J Clean Prod 66:107–112

Lu X, Li C, Wang S, Ye Z, Cheng X (2018) Effect of ferrite phase on the formation and coexistence of 3CaO 3Al2O3 CaSO4 and 3CaO SiO2 minerals. Ceramics-Silikáty 62:67–73

Tregambi C, Solimene R, Montagnaro F, Salatino P, Marroccoli M, Ibris N, Telesca A (2018) Solar-driven production of lime for ordinary Portland cement formulation. Sol Energy 173:759–768

Xu W, Xu J, Liu J, Li H, Cao B, Huang X, Li G (2014) The utilization of lime-dried sludge as resource for producing cement. J Clean Prod 83:286–293

Jawed I, Skalny J (1977) Alkalies in cement: a review I. Forms of alkalies and their effect on clinker formation. Cem Concr Res 7:719–729

Liu X, Liu T, Wu Y, Wang W, Li Y (2013) Effect of alkalis on the mineral formation and properties of alite-sulfoaluminate cement. Adv Cem Res 25:98–103

Huang L, Yan P (2019) Effect of alkali content in cement on its hydration kinetics and mechanical properties. Constr Build Mater 228:116833

Strunge J, Knoefel D, Dreizler I (1986) Influence of alkalies and sulphur on the properties of cement. ZKG Int 39:380–386

Diamond S (1975) A review of alkali-silica reaction and expansion mechanisms 1. Alkalies in cements and in concrete pore solutions. Cem Concr Res 5:329–345

Shih P-Y, Lee P-H, Nian K-J, Lee T-C (2013) Characterization of a mortar made with cement and slag vitrified from a MSWI ash-mix and CMP sludge. Constr Build Mater 38:22–30

Acknowledgements

This research was financially supported by the National Key Research and Development Program of China (2017YFC0210804) and National Key Research and Development Program of China (2018YFC1903602).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Tian-Yong Huang: Senior Engineering, research fields: Comprehensive Utilization of solid waste as building materials, Functional Building Materials.

Rights and permissions

About this article

Cite this article

Li, YM., Wu, XQ., Wang, LJ. et al. Comparative study on utilization of different types of municipal solid waste incineration bottom ash for clinker sintering. J Mater Cycles Waste Manag 22, 1828–1843 (2020). https://doi.org/10.1007/s10163-020-01067-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10163-020-01067-6