Abstract

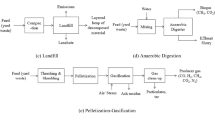

Palm oil mill effluent (POME) is the liquid waste from palm oil mills, and is generally treated using open lagoon technology. However, open lagoons can also be combined with more environmentally friendly technologies. In this study, the analytic hierarchy process (AHP) was used to determine the best combination open lagoon of technology (COLT) for POME treatment. The selected criteria were benefit, opportunity, risk, and cost, with sub-criteria further determined based on these criteria. The sub-criteria were revenue, greenhouse gas reduction, employment absorption, corporate social responsibility, co-processing, environmental risk, marketing risk, technology reliability, investment cost, operation and maintenance cost, and opportunity cost. The alternatives were COLT-composting for fertilizer purpose and COLT-biogas for energy generation purpose. Calculation and analysis was performed on questionnaire data using Expert Choice®. COLT-composting proved to be the superior COLT using tentative performance of alternative in this research, with advantages in benefit, opportunity, and risk. The priority weight for COLT-composting was 0.636. Sensitivity analysis was performed by changing criteria priorities. For COLT-biogas to be considered better than COLT-composting, the cost would need to be weighted more than 0.954.

Similar content being viewed by others

References

Directorate general of Estate Crops of Indonesia, M.o.A., Tree crop estate statistics of Indonesia. 2013–2015 Palm Oil. 2014, Jakarta: Directorate general of Estate Crops. 78

Rahayu AS et al (2015) POME-to-biogas project development in Indonesia. In: Castermans B et al. (eds) Winrock International Jakarta. p 100

Nasution MA (2011) Treatment of POME and production of hydrogen gas using electrocoagulation reactor, in engineering and build environment. National University of Malaysia, Bangi, p 131

Nutongkaew T et al (2014) Physicochemical and biochemical changes during composting of different mixing ratios of biogas sludge with palm oil mill wastes and biogas effluent. J Mater Cycles Waste Manage 16(1):131–140

Kablan MM (2004) Decision support for energy conservation promotion: an analytic hierarchy process approach. Energy Policy 32(10):1151–1158

Qdais HA, Alshraideh H (2016) Selection of management option for solid waste from olive oil industry using the analytical hierarchy process. J Mater Cycles Waste Manage 18(1):177–185

Saaty TL (1980) The analytic hierarchy process: planning, priority setting, resource allocation. McGraw-Hill, India

Stichnothe H, Schuchardt F (2010) Comparison of different treatment options for palm oil production waste on a life cycle basis. Int J Life Cycle Assess 15(9):907–915

Beaudry G et al (2017) Greenhouse gas assessment of palm oil mill biorefinery in Thailand from a life cycle perspective. Biomass Convers Biorefinery 1–16. doi:10.1007/s13399-016-0233-7

Schuchardt F, Darnoko D, Guritno P (2002) Composting of empty oil palm fruit bunch (EFB) with simultaneous evaporation of oil mill waste water (POME). In: International Oil Palm Conference. Indonesia Oil Palm Research Institute, Nusa Dua

Mohammad N, Alam MZ, Kabashi NA (2013) Development of composting process of oil palm industrial wastes by multi-enzymatic fungal system. J Mater Cycles Waste Manage 15(3):348–356

Mohammad N, Alam MZ, Kabashi NA (2015) Optimization of effective composting process of oil palm industrial waste by lignocellulolytic fungi. J Mater Cycles Waste Manage 17(1):91–98

Abbasi T, Tauseef SM, Abbasi SA (2012) Biogas energy. Springer, Berlin

Nasution MA, Herawan T, Rivani M (2014) Analysis of palm biomass as electricity from palm oil mills in North Sumatera. Energy Procedia 47:166–172

Ministry Energy and Mineral Resources of Indonesi (2015) Rencana Strategis Kementerian ESDM Tahun 2015–2019, I.M.o.E.a.M. Resources, Editor. Jakarta

Khawkomol S et al (2013) ANP modeling to select biomass energy plant in rural areas of Thailand. Agri Inform Res 22(2):117–131

Nouri D, Sabour MR, GhanbarzadehLak M (2016) Industrial solid waste management through the application of multi-criteria decision-making analysis: a case study of Shamsabad industrial complexes. J Mater Cycles Waste Manage 1–16

Wang J-J et al (2008) A fuzzy multi-criteria decision-making model for trigeneration system. Energy Policy 36(10):3823–3832

Wijnmalen DJD (2007) Analysis of benefits, opportunities, costs, and risks (BOCR) with the AHP–ANP: A critical validation. Math Comp Model 46(7–8):892–905

De Felice F et al (2014) Inventory management using both quantitative and qualitative criteria in manufacturing system. IFAC Proceed Vol 47(3):8048–8053

Arrieta FRP et al (2007) Cogeneration potential in the Columbian palm oil industry: Three case studies. Biomass Bioenerg 31(7):503–511

Institute, I.O.P.R., Studi Kelayakan Usaha: Pembangkit Listrik Berbasis Biogas Limbah Cair Di Pabrik Pengolahan Kelapa Sawit Betung PT. Perkebunan Nusantara VII (Persero). 2013: Medan

Ariffin MA et al (2016) Medium-scale gasification of oil palm empty fruit bunch for power generation. J Mater Cycles Waste Manage 1–9

Zangeneh A, Jadid S, Rahimi-Kian A (2009) A hierarchical decision making model for the prioritization of distributed generation technologies: a case study for Iran. Energy Policy 37(12):5752–5763

Acknowledgements

The authors would like to thank the Indonesia oil palm research institute (IOPRI) and PT Socfin Indonesia for their support of this research. We also like to express our gratitude and thank to the all participants who were involved in this research questionnaire.

Author information

Authors and Affiliations

Corresponding author

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Nasution, M.A., Wibawa, D.S., Ahamed, T. et al. Selection of palm oil mill effluent treatment for biogas generation or compost production using an analytic hierarchy process. J Mater Cycles Waste Manag 20, 787–799 (2018). https://doi.org/10.1007/s10163-017-0638-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10163-017-0638-9