Abstract

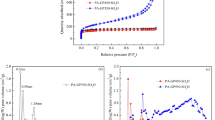

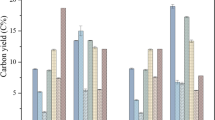

This study conducted gasification and catalytic reforming experiments with the expectation of obtaining new advantages on energy recovery and aimed for the development of an effective catalyst. Initially, the use of thermal gasification technology for waste treatment in line with waste-to-energy strategies was reviewed. Technological systems which have gasification were classified and their current status was discussed. Then, the results of gasification and reforming experiments showed that product gas with 50 % H2 or more was obtained using a Ni catalyst on a mesoporous silica–based SBA-15 support (NiO/SBA-15), which we newly developed. Experiments using wood feedstock revealed that H2 production by the catalyst was better when the NiO content was 20 % (W/W) or more than when another catalyst or the Ni catalyst with a lower Ni loading was used. Tar formation as a by-product was also well controlled by the catalyst, and use of a catalyst with 40 % NiO reduced the tar concentration to less than 0.2 g/\( {\text{m}}^{3}_{\text{N}} \). Experiments using a mixed feedstock of wood and RPF resulted in an increase in hydrocarbon concentration because of insufficient reforming. This finding suggests that future work is required to find a better solution to wood and RPF co-gasification.

Similar content being viewed by others

References

Lu B, Kawamoto K (2015) Thermo-chemical hydrogen production technology from biomass. Curr Org Chem 19:447–454

Kawamoto K, Kuramochi H, Wu W (2004) Current status and future prospects of hydrogen production from biomass and wastes by using a pyrolysis-gasification and reforming process. Waste Manag Res 15:443–455 (in Japanese)

Wu W, Kawamoto K, Kuramochi H (2006) Hydrogen-rich synthesis gas production from waste wood via gasification and reforming technology for fuel cell application. J Mater Cycles Waste Manag 8:70–77

Keim W (1986) C1 Chemistry: potential and developments. Pure Appl Chem. 58:825–832

Ministry of the Environment, Government of Japan (2015) Municipal solid waste emissions and disposal in FY2013. http://www.env.go.jp/en/headline/2137.html. 23 Jan 2015. Accessed 31 Dec 2015

ORIX (2015)A waste processing facility that produces resources. http://www.orix.co.jp/grp/en/story/story_06.html. Accessed 31 Dec 2015

Yamada S, Shimizu M, Miyoshi F (2004) Thermoselect waste gasification and reforming process. JFE Tech Rep 3:21–26

Rapagna S, Jand N, Fosco PU (1998) Catalytic gasification of biomass to produce hydrogen-rich gas. J Hydrog Energy. 23:551–557

Asadullah M, Ito S, Kunimori K, Yamada M, Tomishige K (2002) Biomass gasification to hydrogen and syngas at low temperature: novel catalytic system using fluidized-bed reactor. J Catal 208:255–259

Kawamoto K, Wu W, Kuramochi H (2009) Development of gasification and reforming technology using catalyst at lower temperature for effective energy recovery: hydrogen recovery using waste wood. J Environ Eng 4:1–13

Kobayashi J, Kawamoto K, Fukushima R, Tanaka S (2011) Woody biomass and RPF gasification using reforming catalyst and calcium oxide. Chemosphere 83:1273–1278

Wu C, Wang Z, Wang L, Huang J, Williams PT (2014) Catalytic steam gasification of biomass for a sustainable hydrogen future: influence of catalyst composition. Waste Biomass Valor. 5:175–180

Lu B, Ju Y, Kawamoto K (2014) Conversion of producer gas using NiO/SBA-15 obtained with different synthesis methods. Int J Coal Sci Technol. 1:315–320

Lu B, Kawamoto K (2013) Preparation of the highly loaded and well-dispersed NiO/SBA-15 for methanation of producer gas. Fuel 103:699–704

Aljbour S, Kawamoto K (2013) Bench-scale gasification of cedar wood—part II: effect of operational conditions on contaminant release. Chemosphere 90:1501–1507

Lu B, Kawamoto K (2012) A novel approach for synthesizing ordered mesoporous silica SBA-15. Mater Res Bull 47:1301–1305

Lu B, Inagi Y, Endo A (2011) Characteristics of SBA-15 synthesized by one-step method. J Nanosci Nanotechnol 11:2361–2367

Tagawa T, de la Rama SR, Kawai S, Yamada H (2013) Partial oxidation catalysts derived from Ni-containing alloys for biomass gasification process. Chem Eng Trans 32:583–588

Watanabe T, Takahashi T, Yamagishi T, Matsui T, Kawamoto K (2012) Contaminants in product gas from oxygen-steam gasification of woody biomass. 11th international conference on sustainable energy technologies (SET-2012). #589, Vancouver, Canada

Aljbour S, Kawamoto K (2013) Bench-scale gasification of cedar wood. Part I: effect of operational conditions on product gas characteristics. Chemosphere 90:1495–1500

Acknowledgments

This research was financially supported by The Environment Research and Technology Development Fund (ERTDF), Ministry of the Environment, Government of Japan, Grant No. 3K123004 during April 2012 and March 2015.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Kawamoto, K., Lu, B. Gasification and reforming of biomass and waste samples by means of a novel catalyst. J Mater Cycles Waste Manag 18, 646–654 (2016). https://doi.org/10.1007/s10163-016-0533-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10163-016-0533-9