Abstract

This paper investigated the durability and mechanical properties of landfill leachate collection HDPE pipes which had been made of different weight percent amounts of virgin and reprocessable HDPE compounds (VC and RC). Durability is reported base on the chemical properties, obtained through oxidative induction time (OIT) and melt flow index (MFI) measurements, at the temperature of 50 °C and over a period of 12 months immersion in a synthetic leachate. Mechanical properties are also described according to tensile and pressure tests which had been conducted on the pipes samples. All of the factors were examined had been affected by the addition of RC, but for the special combination the antioxidant depletion was significantly affected by the experimental aging condition and no important changes had been observed in the other pipe properties. The results from OIT tests indicate that the rate of antioxidant depletion is reduced by an increase in the weight percent amounts of RC, during the experimental aging condition. This reduction is probably attributed to the extraction of antioxidants from RC in their recovery process. Finally, although these results are related to the particular HDPE compound, antioxidant formulation and condition examined, but it can be said that the use of clean own reprocessable material for the production of landfill leachate pipes shall be permitted without limitations.

Similar content being viewed by others

References

Tchobanoglous G, Kreit, F (2002) Handbook of solid waste management (2nd Ed.). McGraw-Hill, Inc., New York

Simões C, Costa Pinto L, Bernardo C (2013) Environmental and economic assessment of a road safety product made with virgin and recycled HDPE: a comparative study. J Environ Manage 114:209–215. doi:10.1016/j.jenvman.2012.10.001

Al-Salem S, Lettieri P, Baeyens J (2009) Recycling and recovery routes of plastic solid waste (PSW): a review. Waste Manage 29:2625–2643. doi:10.1016/j.wasman.2009.06.004

Adhikary K, Pang S, Staiger M (2008) Dimensional stability and mechanical behavior of wood–plastic composites based on recycled and virgin high-density polyethylene (HDPE). Compos B 39:807–815. doi:10.1016/j.compositesb.2007.10.005

Usapein P, Chavalparit O (2015) Evaluating the performance of 3R options to reduce landfill wastes using the 3R indicator (3RI): case study of polyethylene factories in Thailand. J Mater Cycles Waste Manage 17:303–311. doi:10.1007/s10163-014-0336-9

Al-Salem S, Lettieri P, Baeyens J (2010) The valorization of plastic solid waste (PSW) by primary to quaternary routes: from re-use to energy and chemicals. Prog Energy Combust Sci 36:103–129. doi:10.1016/j.pecs.2009.09.001

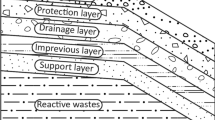

Qian X, Koerner R, Gray D (2002) Geotechnical aspects of landfill design and construction. Prentice-Hall, Inc., New Jersey

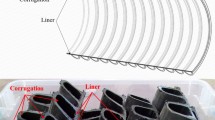

Brachman R (2011) Design and performance of plastic drainage pipes in environmental containment facilities. J ASTM Int 8:1–13. doi:10.1520/JAI102852

Krushelnitzky R, Brachman R (2013) Buried high-density polyethylene pipe deflections at elevated temperatures. Geotext Geomembr 40:69–77. doi:10.1016/j.geotexmem.2013.08.001

Krushelnitzky R, Brachman R (2011) Antioxidant depletion in high-density polyethylene pipes exposed to synthetic leachate and air. Geosynth Int 18:63–73. doi:10.1680/gein.2011.18.2.63

Krushelnitzky R, Brachman R (2009) Measured deformations and calculated stresses of high-density polyethylene pipes under very deep burial. Can Geotech J 46:650–664. doi:10.1139/T09-011

Brachman R, Krushelnitzky R (2005) Response of a landfill drainage pipe buried in a trench. Can Geotech J 42:752–762. doi:10.1139/t05-005

Brachman R, Krushelnitzky R (2002) Stress concentrations around circular holes in perforated drainage pipes. Geosynth Int 9:189–213. doi:10.1680/gein.9.0215

Brachman R, Moore I, Rowe R (2000) Local strain on a leachate collection pipe. Can J Civil Eng 27:1273–1285. doi:10.1139/l00-074

Ewais A, Rowe R, Scheirs J (2014) Degradation behavior of HDPE geomembranes with high and low initial high-pressure oxidative induction time. Geotext Geomembr 42:111–126. doi:10.1016/j.geotexmem.2014.01.004

Rowe R, Ewais A (2014) Antioxidant depletion from five geomembranes of same resin but of different thicknesses immersed in leachate. Geotext Geomembr 42:540–554. doi:10.1016/j.geotexmem.2014.08.001

Ewais A, Rowe R (2014) Effect of aging on the stress crack resistance of an HDPE geomembrane. Polym Degrad Stabil 109:194–208. doi:10.1016/j.polymdegradstab.2014.06.013

Abdelaal F, Rowe R (2014) Effect of high temperatures on antioxidant depletion from different HDPE geomembranes. Geotext Geomembr 42:284–301. doi:10.1016/j.geotexmem.2014.05.002

Rowe R, Islam M, Hsuan Y (2010) Effects of thickness on the aging of HDPE geomembranes. J Geotech Geoenviron 136:299–309. doi:10.1061/(ASCE)GT.1943-5606.0000207

Rowe R, Islam M, Brachman R, Arnepalli D, Ewais A (2010) Antioxidant depletion from a high density polyethylene geomembrane under simulated landfill conditions. J Geotech Geoenviron 136:930–939. doi:10.1061/(ASCE)GT.1943-5606.0000302

Rowe R, Rimal S, Sangam H (2009) Ageing of HDPE geomembrane exposed to air, water and leachate at different temperatures. Geotext Geomembr 27:137–151. doi:10.1016/j.geotexmem.2008.09.007

Rowe R, Islam M, Hsuan Y (2008) Leachate chemical composition effects on OIT depletion in an HDPE geomembrane. Geosynth Int 15:136–151. doi:10.1680/gein.2008.15.2.136

Rowe R, Rimal S (2008) Depletion of antioxidants from an HDPE geomembrane in a composite liner. J Geotech Geoenviron 134:68–78. doi:10.1061/(ASCE)1090-0241(2008)134:1(68)

ISO 4427 (2007) Plastics piping systems—Polyethylene (PE) pipes and fittings for water supply

Farshad M (2006). Plastic pipe systems: failure investigation and diagnosis, Elsevier Ltd, London

Islam M, Rowe R (2007) Leachate composition and antioxidant depletion from HDPE geomembranes. Geosynthetics, IFAI

Hsuan Y, Koerner R (1998) Antioxidant depletion lifetime in high-density polyethylene geomembranes. J Geotech Geoenviron 124:532–541. doi:10.1061/(ASCE)1090-0241(1998)124:6(532)

ISO 15270 (2008) Plastics—guidelines for the recovery and recycling of plastics waste. http://www.iso.org/iso/catalogue_detail?csnumber=45089. Accessed 20 June 2015

Tátraaljai D, Vámos M, Orbán-Mester Á, Staniek P, Földes E, Pukánszky B (2014) Performance of PE pipes under extractive conditions: effect of the additive package and processing. Polym Degrad Stabil 99:196–203. doi:10.1016/j.polymdegradstab.2013.11.005

ISO 11357 (2009) Plastics—differential scanning calorimetry (DSC). http://www.iso.org/iso/iso_catalogue/catalogue_tc/catalogue_detail.htm?csnumber=41637. Accessed 20 June 2015

ISO 1133 (2011) Plastics—determination of the melt mass-flow rate (MFR) and melt volume-flow rate (MVR) of thermoplastics. http://www.iso.org/iso/catalogue_detail.htm?csnumber=44273. Accessed 20 June 2015

ISO 6259 (2015) Thermoplastics pipes—determination of tensile properties. http://www.iso.org/iso/home/store/catalogue_tc/catalogue_detail.htm?csnumber=62422. Accessed 20 June 2015

ISO 1167 (2006) Thermoplastics pipes, fittings and assemblies for the conveyance of fluids—determination of the resistance to internal pressure. http://www.iso.org/iso/iso_catalogue/catalogue_tc/catalogue_detail.htm?csnumber=33981. Accessed 20 June 2015

ISO 2818 (1994) Plastics—preparation of test specimens by machining. http://www.iso.org/iso/iso_catalogue/catalogue_tc/catalogue_detail.htm?csnumber=7816. Accessed 20 June 2015

Acknowledgments

This research was funded by the Amirkabir University of Technology. Valuable contributions from Mr. Mohammadreza Beheshtian Ardakani are gratefully acknowledged. The authors are grateful to their industrial partner Pooyashiraz Co. (Tehran and Shiraz, Iran) for providing the pipes tested.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Beheshtian Ardakani, M., Ebadi, T. & Mir Mohammad Hosseini, S.M. The effects of using reprocessable material on the durability and mechanical properties of landfill leachate collection HDPE pipes. J Mater Cycles Waste Manag 19, 1166–1176 (2017). https://doi.org/10.1007/s10163-016-0502-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10163-016-0502-3