Abstract

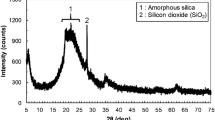

With the air pollution control standards getting increasingly stricter, gas cleaning processes with higher capture efficiency of pollutants in iron-ore sintering gas cleaning were applied in China, and fine residue, an emerging hazardous waste containing high content of heavy metals as well as Polychlorinated dibenzo-p-dioxins and dibenzofurans (PCDD/Fs) were produced. Disposal of the residues in secure landfill after adequate solidification/stabilization was the main solution. The feasibility of solidification/stabilization process using cement and chelating agent was investigated in this study. Leaching concentration of Lead (Pb) and Selenium (Se) exceeded the identification limit, and the content of PCDD/Fs was rather low, so the immobilization of Pb and Se was the main objective of solidification/stabilization. The result showed that leaching concentrations of Pb in the solidified products were lower than 5 mg/L when the addition of cement was 20 % or chelating agent 1 %. However, leaching concentration of Se fluctuated between 0.6 and 0.8 mg/L even the cement addition reached 45 % or chelating agent 3 %. Geochemical modelling using PHREEQC indicated that Se in the residue mainly existed as highly soluble SeO4 2−.

Similar content being viewed by others

References

State Environmental Protection Administration (2013) The state environmental protection standards “twelfth five-year” development plan

Fleischanderl A, Fingerhut W (2007) MEROS R-latest state of the art in dry sinter gas cleaning. In: China iron and steel annual meeting proceedings pp 453–457

Tang SW, Ding XL, Zhao K (2008) Study on the craft technology scheme of the sinter flue gas desulphurization of Ma’anshan Iron and Steel Co.Ltd. Metal World 6:20–23

Plattner T, Fleischanderl A, Neuhold R(2011) Simetal MEROS at Masteel and latest innovations-substantial emission reduction at sinterplants. In: Siemens VAI metals symposium 5, pp 18–21

Zhou CH, Liu YL, Chen GY, Wu CG, Rao L (2011) Masteel sintering flue gas desulfurization and dy-products comprehensive utilization research. In: China iron and steel annual meeting proceedings

Yang JS (2007) Solid waste engineering treatment disposal and resourcization. TsingHua University Press, China

Nie YF, Li JH (2003) The development trendency of hazardous waste disposal technology at home and abroad. In: International symposium on environmental protection industry

Barth EF (1990) An overview of the history, present status and future direction of solidification/stabilization technologies for hazardous waste treatment. J Hazard Mater 24(2–3):103–109

Jiang JG, Wang W (1998) The history, present status and development of solidification/stabilization technology in treating with hazardous waste. Adv Environ Sci 6(1):55–62

Malviya R, Chaudhary R (2006) Factors affecting hazardous waste solidification/stabilization: a review. J Hazard Mater 137(1):267–276

Chen QY, Tyrer M, Hills CD, Yang XM, Carey P (2009) Immobilisation of heavy metal in cement-based solidification/stabilization: a review. Waste Manag 29(1):390–403

Batchelor B (2006) Overview of waste stabilization with cement. Waste Manag 26(7):689–698

Bishop PL (1988) Leaching of inorganic hazardous constituents from stabilized/solidified hazardous wastes. Hazard Waste Hazard Mater 5(2):129–143

Gong P, Bishop PL (2003) Evaluation of organics leaching from solidified/stabilized hazardous wastes using a powder reactivated carbon additive. Environ Technol 24(4):445–455

State Environmental Protection Administration (2007) HJ/T299-2007 solid waste-extraction procedure for leaching toxicity-sulphuric acid and nitric acid method. Beijing Standards Press of China, China

State Environmental Protection Administration (2008) GB16889-2008 Standard for pollution control on the landfill site of municipal solid waste. Beijing Standards Press of China, China

State Environmental Protection Administration (2007) HJ/T300-2007 Solid waste-extraction procedure for leaching toxicity-acetic acid buffer solution method. Beijing Standards Press of China, China

State Environmental Protection Administration (1997) GB5086.1-1997 Test method standard for leaching toxicity of solid wastes Roll over leaching procedure. Beijing Standards Press of China, China

Guo J, Ji Y, Hu XF, Xu Z (2012) Volatile organic compounds and metal leaching from composite products made from fiberglass-resin portion of printed circuit board waste. Environ Sci Technol 46(2):1028–1034

Dijkstra JJ, Van der Sloot HA, Comans RNJ (2002) Process identification and model development of contaminant transport in MSWI bottom ash. Waste Manag 22(5):531–541

Gomes PIA, Asaeda T (2013) Phytoremediation of heavy metals by calcifying macro-algae (Nitella pseudoflabellata): implications of redox insensitive end products. Chemosphere 92(10):1328–1334

State Environmental Protection Administration (2001) GB18598-2001 Standard for pollution control on the security landfill site for hazardous wastes. Beijing Standards Press of China, China

Shah P, Strezov V, Stevanov C, Nelson PF (2007) Speciation of arsenic and selenium in coal combustion products. Energy Fuels 21(2):506–512

Ghosh-Dastidar A, Mahuli S, Agnihotri R, Fan LS (1996) Selenium capture using sorbent powders: mechanism of sorption by hydrated lime. Environ Sci Technol 30(2):447–452

Li HY (2001) Valence changes of selenium and its influential factors in soil solution. J Hunan Agric Univ (Nat Sci) 27(2):139–142

Acknowledgments

This research was financially supported by the Siemens CKI project.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Song, M., Liu, J. & Xu, S. Characterization and solidification/stabilization of iron-ore sintering gas cleaning residue. J Mater Cycles Waste Manag 17, 790–797 (2015). https://doi.org/10.1007/s10163-014-0312-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10163-014-0312-4