Abstract

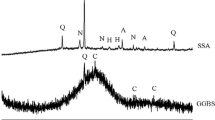

This article investigates the effects of stone powder sludge on the microstructure and strength development of alkali-activated fly ash and blast furnace slag mixes. Stone powder sludge produced from a crushed aggregate factory was used to replace fly ash and granulated blast furnace slag at replacement ratios of 0%, 10%, 20%, and 30% by mass. The unit weight and compressive strength of the samples were measured, and scanning electron microscopy/energy dispersive spectroscopy and X-ray diffraction (XRD) analyses were performed. The test results indicated that the compressive strength of alkali-activated blast furnace slag mixes using stone powder sludge was higher than that of the alkali-activated blast furnace slag control mix, but the compressive strength of alkali-activated fly ash mixes decreased with increasing replacement ratio of stone powder sludge. Microscopy results indicated that for alkaliactivated blast furnace slag samples, broken surfaces were more evident than for the alkali-activated fly ash samples. For all XRD diagrams, broad and diffuse peaks were observed around 2θ = 35° (d = 2.96–3.03 Å), implying amorphous or short-ordering structure phases.

Similar content being viewed by others

References

Kim JM, Jeong JY, Choi SJ, Kim BJ (2006) The density and strength properties of lightweight foamed concrete using stone-powder sludge in hydrothermal reaction condition. J Korea Concrete Inst 18:687–693

Davidovits J (1989) Geopolymers: inorganic polymeric new materials. J Therm Anal 37:1633–1656

Palomo A, López de la Fuente JI (2003) Alkali-activated cementitious materials: Alternative matrices for the immobilization of hazardous wastes. Cement Concrete Res 33:281–288

Mallicoat S, Sarin P, Kriven WM (2005) Novel alkali-bonded ceramic filtration membranes. Ceram Eng Sci Proc 26:26–37

Gartner E (2004) Industrially interesting approaches to “low-CO2” cements. Cement Concrete Res 34:1489–1498

Carroll D, Dougherty A, Nisbet M, O’Hare A (1998) U.S. Portland cement industry, concrete and global climate. In: Proceedings of the 1998 91st Annual Meeting and Exhibition. Air and Waste management Association

Xu A (1997) Fly ash in concrete. In: Chandra S (ed) Waste materials used in concrete manufacturing. Noyes, Westwood, NJ, pp 141–173

Yip CK (2004) The role of calcium in geopolymerisation. PhD Thesis, The University of Melbourne, Department of Chemical Engineering, Melbourne

Davidovits J (1994) Properties of geopolymer cements. In: Proceedings of the First International Conference on Alkaline Cements and Concrete. Scientific Research Institute on Binders and Materials, Kiev, Ukraine, pp 131–149

Sofi M, van Deventer JSJ, Mendis PA, Lukey GC (2007) Bond performance of reinforcing bars in inorganic polymer concrete (IPC). J Mater Sci 42:3107–3116

Kim CK, Bae KH (2001) Hydrothermal preparation of artificial stone plate from stone powder sludge. Korean J Crystallogr 12:216–221

Takayuki F, Masaru Y (2002) Applicability of crush stone powder and recycled concrete powder to high-fluidity concrete. J Soc Mater Sci 51:1105–1110

Khale D, Chaudhary R (2007) Mechanism of geopolymerization and factors influencing its development: a review. J Mater Sci 42:729–746

Collins F, Sanjayan JG (2000) Cracking tendency of alkaliactivated slag concrete subjected to restrained shrinkage. Cement Concrete Res 30:791–798

Collins F, Sanjayan JG (2000) Effect of pore size distribution on drying shrinkage of alkali-activated slag concrete. Cement Concrete Res 30:1401–1406

Krizan D, Zivanovic B (2002) Effect of dosage and modulus of water glass on early hydration of alkali-slag cements. Cement Concrete Res 32:1181–1188

Wang SD, Scrivener KL (1995) Hydration products of alkali activated slag cement. Cement Concrete Res 25:567–571

Puertas F, Fernandez-Jimenez A (2003) Mineralogical and microstructural characterization of alkali-activated fly ash/slag pastes. Cement Concrete Res 25:287–292

Taylor HFW (1997) Cement chemistry, 2nd edn. Thomas Telford, London

Richardson IG, Brough AR, Groves GW, Dobson CM (1994) The characterization of hardened alkali-activated blast-furnace slag paste and the nature of the calcium silicate hydrate (C-S-H). Cement Concrete Res 24:813–829

Song S, Jennings HM (1999) Pore solution of alkali-activated ground granulated blast-furnace slag. Cement Concrete Res 29:159–170

Escalante-Garcia JI, Fuentes AF, Gorokhovsky A, Fraire-Luna PE, Mendoza-Suarez G (2003) Hydration products and reactivity of blast-furnace slag activated by various alkalis. J Am Ceram Soc 86:2148–2153

Shilling PJ, Roy A, Eaton HC (1994) Microstructure, strength and reaction products of ground granulated blast-furnace slag activated by highly concentrated NaOH solution. J Mater Res 91:188–197

Heller L, Taylor HFW (1956) Crystallographic data for the calcium silicates. HMSO, London

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Choi, S.J., Jun, S.S., Oh, J.E. et al. Properties of alkali-activated systems with stone powder sludge. J Mater Cycles Waste Manag 12, 275–282 (2010). https://doi.org/10.1007/s10163-010-0297-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10163-010-0297-6