Abstract

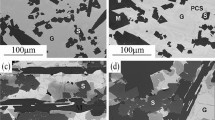

To reutilize molten slag derived from an ash melting process, the lead volatilization mechanism under reducing conditions was investigated. Reducing conditions were established by introducing a CO-CO2-N2 gas mixture to the reactor or by adding graphite to the molten slag prior to the experiments. As samples, two types of simulated molten slag composed of CaO-SiO2-Al2O3 mixed with PbO were used and the lead volatilization behavior was studied at 1773 K. It was found that the lead volatilization rate increased on increasing the amount of reducing agent for both graphite and the CO-CO2 gas mixture. For the CO-CO2 reducing gas mixture, this increase was mainly attributed to PbO conversion to Pb. For the addition of graphite, the increase in lead volatilization ratio was considered to partially result from PbO conversion to Pb and partially from a reaction of graphite with SiO2 yielding volatile SiO. The volatile SiO gas was then emitted from the furnace, which brought about a reduction in the SiO2 content of the slag. As a result, the slag viscosity decreased, which led to an enhancement of the lead volatilization ratio.

Similar content being viewed by others

References

Sakamoto K, Kunii K, Kusamichi T, Murakoshi K, Kawabata H, Kokado M (2001) Evaporation behavior of heavy metals in municipal incinerator melting fly ash. R&D Kobe Steel Eng Rep 51:18–22

Osada S, Osada M, Kokado M, Tokuda M (2004) Thermodynamics study of the behavior of elements with low boiling points in the melting process. J Jpn Soc Waste Manag Experts 15:353–362

Mihara N, Nakada H, Kuchar D, Kubota M, Matsuda H (2006) Volatilization behavior of lead from molten slag under the simulated conditions of municipal solid waste melting. In: Proceedings of the Fourth International Conference on Combustion, Incineration/Pyrolysis and Emission Control. September 26–29, Kyoto, Japan, pp 571–574

Shimoo T, Ando S, Kimura H (1983) Evolution rates of Mg and SiO from CaO-SiO2-MgO slag melted in a graphite crucible. J Jpn Inst Met 47:114–120

Azuma K, Okamura K, Fukutomi M (1976) Reduction rate of zinc oxide in zinciferous slag. J Min Metall Inst Jpn 92:171–176

Shigemi A (1979) Handbook of iron smelting (in Japanese). Chijin Shokan, Japan

The Japan Institute of Metals (1996) Physical chemistry of metals. Maruzen, Japan

Marchin JS, Yee TB (1948) Viscosity studies of the system CaO-MgO-Al2O3-SiO2: II CaO-Al2O3-SiO2. J Am Ceram Soc 31:200–204

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Nakada, H., Mihara, N., Kawaguchi, Y. et al. Volatilization behavior of lead from molten slag under conditions simulating municipal solid waste melting. J Mater Cycles Waste Manag 10, 19–23 (2008). https://doi.org/10.1007/s10163-007-0193-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10163-007-0193-x