Abstract

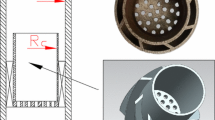

The mixing characteristics of a passive scalar in the turbulent flow of a selective catalytic reduction process were numerically and experimentally investigated, focusing especially on an injection nozzle with multiple holes for the reducing agent. The multihole injection nozzle studied has six holes that are perpendicular to the ambient flue gas flow and are located near the tip of the nozzle. Large eddy simulation was applied to the turbulent flow and mixing fields to elucidate the mixing mechanism of the proposed nozzle compared with the single-hole nozzle that is commonly used in the conventional selective catalytic reduction process. From the results, there exist broader regions of higher turbulent intensities for the multihole nozzle than for the conventional single-hole nozzle. These regions are well matched with the positions of high vorticity in the near upstream region of the jet flow issuing from the multiple holes of the nozzle. Consequently, the high turbulent intensities and vorticity magnitudes lead to intensified mixing between the flue gas and the reducing agent. Hence, the most suitable molar ratio between NOx and the reducing agent for the catalytic reaction can be easily obtained within a shorter physical mixing length as a result of the enhanced scalar mixing. Finally, the numerical results were applied to a trial design version of a multihole nozzle, and this nozzle was experimentally tested to confirm its mixing performance.

Similar content being viewed by others

References

Ostberg M, Johansen KD, Johnsson JE (1997) Influence of mixing on the SNCR process. Chem Eng Sci 52:2511–2525

Oliva M, Alzueta MU, Milera A, Bilbao R (2000) Theoretical study of the influence of mixing in the SNCR process. Comparison with pilot-scale data. Chem Eng Sci 55:5321–5332

Miller RS, Madnia CK, Givi P (1995) Numerical simulation of non-circular jets. Comput Fluids 24:1–25

Singh G, Sundararajan T, Bhaskaran KA (2003) Mixing and entrainment characteristics of circular and noncircular confined jets. J Fluid Eng 125:835–842

Chua LP, Yu SCM, Wang XK (2003) Flow visualization and measurements of a square jet with mixing tabs. Exp Therm Fluid Sci 27:731–744

Tehrani FB, Shahmir A, Kashani AH (2004) Numerical analysis of a single row of coolant jets injected into a heated crossflow. J Comput Appl Math 168:53–63

Jones WP, Wille M (1996) Large-eddy simulation of a plane jet in a cross flow. Int J Heat Fluid Flow 17:296–306

Wegner B, Huai Y, Sadiki A (2004) Comparative study of turbulent mixing in jets in cross-flow configurations using LES. Int J Heat Fluid Flow 25:767–775

Mathieu J, Scott J (2000) An introduction to turbulent flow. Cambridge University Press, pp 327–366

Hochdorfer E, Gschwind P, Kottke V (1995) Twisted-tape vortex generators in duct flow: flow field and heat and mass transfer. Exp Therm Fluid Sci 11:262–269

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Choi, H.S., Kim, S.J. & Kim, K.T. Enhancement of turbulent scalar mixing and its application by a multihole nozzle in selective catalytic reduction of NOx. J Mater Cycles Waste Manag 10, 1–6 (2008). https://doi.org/10.1007/s10163-007-0190-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10163-007-0190-0