Abstract

Ethylene-propylene block copolymer (EbP) is a vital component in impact polypropylene copolymer (IPC), yet its distribution in the multiphase composite material and how it influences the phase structure and the mechanical properties are not well understood. In this work, four IPCs were investigated by atomic force microscopy-infrared (AFM-IR) to assess the phase compositions in situ, based on which in conjunction with the chain microstructure information obtained ex situ the distributions of the copolymer components were derived for each alloy. For the IPCs whose EbP comprises long P and long E segments, the EbP fraction was found to phase separate from the rubber and the PP matrix to form the cores of the disperse particles with the E-P segmented copolymer (EsP). In contrast, in the IPC with EbP composed of long P and short E segments, the EbP fraction formed an outer shell for the rubber particles with the cores comprising the EsP alone, and this IPC, containing a lower E comonomer content than its counterpart, exhibited both better impact resistance and higher flexural modulus. These results clarify how the chain structure of EbP governs the phase morphology in IPC, which in turn impacts the properties of the composite material.

Similar content being viewed by others

References

Cecchin, G.; Marchetti, E.; Baruzzi, G. On the mechanism of polypropene growth over MgCl2/TiCl4 catalyst systems. Macromol. Chem. Phys. 2001, 202, 1987–1994.

Galli, P.; Vecellio, G. Polyolefins: the most promising large-volume materials for the 21st century. J. Polym. Sci., Part A: Polym. Chem. 2004, 42, 396–415.

Tong, C. Y.; Lan, Y.; Chen, Y.; Chen, Y.; Yang, D. C.; Yang, X. N. The functions of crystallizable ethylene-propylene copolymers in the formation of multiple phase morphology of high impact polypropylene. J. Appl. Polym. Sci. 2012, 123, 1302–1309.

Tan, H. S.; Li, L.; Chen, Z. N.; Song, Y. H.; Zheng, Q. Phase morphology and impact toughness of impact polypropylene copolymer. Polymer 2005, 46, 3522–3527.

Xu, J. T.; Feng, L. X.; Yang, S. L.; Wu, Y. N.; Yang, Y. Q.; Kong, X. M. Separation and identification of ethylene-propylene block copolymer. Polymer 1997, 38, 4381–4385.

Gahleitner, M.; Tranninger, C.; Doshev, P. Herorpphacic copolymers of polypropylene: development, design principles, and future challenges. J. Appl. Polym. Sci. 2013, 130, 3028–3037.

Chen, F.; Qiu, B.; Shangguan, Y.; Song, Y.; Zheng, Q. Correlation between impact properties and phase structure in impact polypropylene copolymer. Mater. Design 2015, 69, 56–63.

Kim, G. M.; Michler, G. H. Micromechanical deformation processes in toughened and particle-filled semicrystalline polymers: Part 1. Characterization of deformation processes in dependence on phase morphology. Polymer 1998, 39, 5689–5697.

Liu, X.; Guo, M.; Wei, W. Stress-whitening of high-impact poly(propylene): characterization and analysis. Macromol. Symp. 2012, 312, 130–138.

Li, F.; Gao, Y.; Zhang, Y.; Jiang, W. Design of high impact thermal plastic polymer composites with balanced toughness and rigidity: Toughening with core-shell rubber modifier. Polymer 2020, 191, 122237.

Chen, F.; Shangguan, Y.; Jiang, Y.; Qiu, B.; Luo, G.; Zheng, Q. Toughening with little rigidity loss and mechanism for modified polypropylene by polymer particles with core-shell structure. Polymer 2015, 65, 81–92.

Li, R.; Zhang, X.; Zhao, Y.; Hu, X.; Zhao, X.; Wang, D. New polypropylene blends toughened by polypropylene/poly(ethylene-co-propylene) in-reactor alloy: Compositional and morphological influence on mechanical properties. Polymer 2009, 50, 5124–5133.

Cai, H. J.; Luo, X. L.; Ma, D. Z.; Wang, J. M.; Tan, H. S. Structure and properties of impact copolymer polypropylene. I. Chain structure. J. Appl. Polym. Sci. 1999, 71, 93–101.

Cheruthazhekatt, S.; Pijpers, T. F. J.; Harding, G. W.; Mathot, V. B. F.; Pasch, H. Multidimensional analysis of the complex composition of impact polypropylene copolymers: combination of TREF, SEC-FTIR-HPer DSC, and high temperature 2D-LC. Macromolecules 2012, 45, 2025–2034.

Fernandez, A.; Teresa Exposito, M.; Pena, B.; Berger, R.; Shu, J.; Graf, R.; Spiess, H. W.; Garcia-Munoz, R. A. Molecular structure and local dynamic in impact polypropylene copolymers studied by preparative TREF, solid state NMR spectroscopy, and SFM microscopy. Polymer 2015, 61, 87–98.

Xue, Y.; Fan, Y.; Bo, S.; Ji, X. Characterization of the microstructure of impact polypropylene alloys by preparative temperature rising elution fractionation. Eur. Polym. J. 2011, 47, 1646–1653.

Zhang, Y. Q.; Fan, Z. Q.; Feng, L. X. Influences of copolymerization conditions on the structure and properties of isotactic polypropylene/ethylene-propylene random copolymerin situ blends. J. Appl. Polym. Sci. 2002, 84, 445–453.

Zhu, H.; Han, C. C.; Wang, D. Phase structure and crystallization behavior of polypropylene in-reactor alloys: insights from both inter- and intramolecular compositional heterogeneity. Macromolecules 2008, 41, 826–833.

Zhang, C.; Shangguan, Y.; Chen, R.; Wu, Y.; Chen, F.; Zheng, Q.; Hu, G. Morphology, microstructure and compatibility of impact polypropylene copolymer. Polymer 2010, 51, 4969–4977.

Chen, Y.; Chen, Y.; Chen, W.; Yang, D. Multilayered core-shell structure of the dispersed phase in high-impact polypropylene. J. Appl. Polym. Sci. 2008, 108, 2379–2385.

Song, S.; Feng, J.; Wu, P. Relaxation of shear-enhanced crystallization in impact-resistant polypropylene copolymer: insight from morphological evolution upon thermal treatment. Polymer 2010, 51, 5267–5275.

Qiu, B. W.; Chen, F.; Shangguan, Y. G.; Lin, Y.; Zheng, Q. Effects of composition on microstructure and crystallization behavior for impact polypropylene copolymer investigated by restructuring the complex core-shell dispersed particles in ternary blends. Chinese J. Polym. Sci. 2015, 33, 95–108.

Rungswang, W.; Saendee, P.; Thitisuk, B.; Pathaweeisariyakul, T.; Cheevasrirungruang, W. Role of crystalline ethylene-propylene copolymer on mechanical properties of impact polypropylene copolymer. J. Appl. Polym. Sci. 2013, 128, 3131–3140.

Dazzi, A.; Glotin, F.; Carminati, R. Theory of infrared nanospectroscopy by photothermal induced resonance. J. Appl. Phys. 2010, 107, 124519.

Dazzi, A.; Prater, C. B. AFM- IR: technology and applications in nanoscale infrared spectroscopy and chemical imaging. Chem. Rev. 2017, 117, 5146–5173.

Dazzi, A.; Prazeres, R.; Glotin, F.; Ortega, J. M. Local infrared microspectroscopy with subwavelength spatial resolution with an atomic force microscope tip used as a photothermal sensor. Opt. Lett. 2005, 30, 2388–2390.

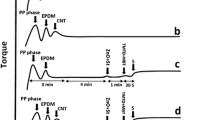

Tang, F.; Bao, P.; Su, Z. Analysis of nanodomain composition in high-impact polypropylene by atomic force microscopy-infrared. Anal. Chem. 2016, 88, 4926–4930.

Tang, F.; Bao, P.; Roy, A.; Wang, Y.; Su, Z. In-situ spectroscopic and thermal analyses of phase domains in high-impact polypropylene. Polymer 2018, 142, 155–163.

Li, C.; Wang, Z.; Liu, W.; Ji, X.; Su, Z. Copolymer distribution in core-shell rubber particles in high-impact polypropylene investigated by atomic force microscopy-infrared. Macromolecules 2020, 53, 2686–2693.

Agosti, E.; Zerbi, G.; Ward, I. M. Structure of the skin and core of ultradrawn polyethylene films by vibrational spectroscopy. Polymer 1992, 33, 4219–4229.

Kissin, Y. V.; Tsvetkova, V. I.; Chirkov, N. M. The stereoregularity of polypropylene from IR and NMR data. Eur. Polym. J. 1972, 8, 529–546.

Hagemann, H.; Snyder, R. G.; Peacock, A. J.; Mandelkern, L. Quantitative infrared methods for the measurement of crystallinity and its temperature dependence: polyethylene. Macromolecules 2002, 22, 3600–3606.

Zhu, X.; Yan, D.; Yao, H.; Zhu, P. In situ FTIR spectroscopic study of the regularity bands and partial-order melts of isotactic poly(propylene). Macromol. Rapid Commun. 2000, 21, 354–357.

Chen, J. H.; Zhong, J. C.; Cai, Y. H.; Su, W. B.; Yang, Y. B. Morphology and thermal properties in the binary blends of poly(propylene-co-ethylene) copolymer and isotactic polypropylene with polyethylene. Polymer 2007, 48, 2946–2957.

Li, R.; Ji, X. L. The relationship between ethylene content and properties of high impact polypropylene. Manuscript in preparation.

Liu, W.; Zhang, J.; Hong, M.; Li, P.; Xue, Y.; Chen, Q.; Ji, X. Chain microstructure of two highly impact polypropylene resins with good balance between stiffness and toughness. Polymer 2020, 188, 122146.

van der Wal, A.; Verheul, A. J. J.; Gaymans, R. J. Polypropylene-rubber blends: 4. The effect of the rubber particle size on the fracture behaviour at low and high test speed. Polymer 1999, 40, 6057–6065.

Kim, S. D.; Choi, Y.; Choi, W.; Choi, C.; Chun, Y. S. Effect of ethylene-propylene copolymer composition on morphology and surface properties of impact poly(propylene) copolymer. Macromol. Symp. 2012, 312, 27–33.

Rungswang, W.; Jarumaneeroj, C.; Jirasukho, P.; Juabrum, S.; Pakawanit, P.; Soontaranon, S.; Rugmai, S. Tiree-resoledd SAXS/WAXD under tensile deformation: role of segmental ethylene-propylene copolymers in impact-resistant polypropylene copolymers. ACS Appl. Polym. Mater. 2021, 3, 6394–6406.

Santonja-Blasco, L.; Rungswang, W.; Alamo, R. G. Influence of chain microstructure on liquid-liquid phase structure and crystallization of dual reactor Ziegler-Natta made impact propylene-ethylene copolymers. Ind. Eng. Chem. Res. 2017, 56, 3270–3282.

Acknowledgments

This work was financially supported by the National Natural Science Foundation of China (No. 52073277) and the Science and Technology Department of Fujian Province (No. 2020HZ06019).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

The authors declare no interest conflict.

Rights and permissions

About this article

Cite this article

Tang, YH., Zhang, N., Bao, W. et al. Critical Role of Ethylene-Propylene Block Copolymer in Impact Polypropylene Copolymer. Chin J Polym Sci 42, 344–351 (2024). https://doi.org/10.1007/s10118-023-3058-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10118-023-3058-4