Abstract

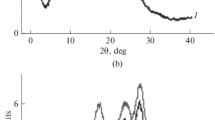

For the first time, a highly crystalline porous shish-kebab structure with a high degree of crystallinity was obtained by using a combination of two methods for the formation of porous polymeric materials. A treatment procedure using supercritical carbon dioxide (scCO2) was carried out for oriented ultrahigh molecular weight polyethylene (UHMWPE) films, which provided special conditions for the crystallization of dissolved UHMWPE macromolecules on the surface of oriented UHMWPE crystals. The prepared porous materials were investigated by scanning electron microscopy (SEM) and differential scanning calorimetry (DSC). The particularity of the obtained porous shish-kebab is the absence of the amorphous phase between lamellar crystals (kebabs). The obtained pores had an oval shape, and they were oriented in the orientation direction of the UHMWPE macromolecules. The pore size ranged from 0.05 µm to 4 µm. Controlling the conditions for the crystallization of the UHMWPE macromolecules using supercritical CO2 gives the possibility to control the size of both lamellar disks and pores formed.

Similar content being viewed by others

References

Senra, M. R.; de Fátima Vieira Marques, M. Synthetic polymeric materials for bone replacement. J. Compos. Sci. 2020, 4, 191.

Maksimkin, A. V.; Senatov, F. S.; Niaza, K.; Dayyoub, T.; Kaloshkin, S. D. Ultra-high molecular weight polyethylene/titanium-hybrid implant for bone-defect replacement. Materials 2020, 13, 3010.

Ustyugov, A. A.; Sipyagina, N. A.; Malkova, A. N.; Straumal, E. A.; Yurkova, L. L.; Globa, A. A.; Lapshina, M. A.; Chicheva, M. M.; Chaprov, K. D.; Maksimkin, A. V.; Lermontov, S. A. 3D neuronal cell culture modeling based on highly porous ultra-high molecular weight polyethylene. Molecules 2022, 27, 2087.

Rashidi, S.; Esfahani, J. A.; Karimi, N. Porous materials in building energy technologies—a review of the applications, modelling and experiments. Renew. Sustain. Energy Rev. 2018, 91, 229–247.

Aizawa, T.; Wakui, Y. Correlation between the porosity and permeability of a polymer filter fabricated via CO2-assisted polymer compression. Membranes 2020, 10, 391.

Li, R.; Gao, P. Nanoporous UHMWPE Membrane separators for safer and high-power-density rechargeable batteries. Glob. Chall. 2017, 1, 1700020.

Mathew, D. E.; Gopi, S.; Kathiresan, M.; Rani, G. J.; Thomas, S.; Stephan, A. M. A porous organic polymer-coated permselective separator mitigating self-discharge of lithium-sulfur batteries. Mater. Adv. 2020, 1, 648–657.

Castejón, P.; Habibi, K.; Saffar, A.; Ajji, A.; Martínez, A. B.; Arencón, D. Polypropylene-based porous membranes: influence of polymer composition, extrusion draw ratio and uniaxial strain. Polymers 2017, 10, 33.

Wang, L.; Wu, Y. K.; Ai, F. F.; Fan, J.; Xia, Z. P.; Liu, Y. Hierarchical porous polyamide 6 by solution foaming: synthesis, characterization and properties. Polymers 2018, 10, 1310.

Cao, Y. C.; Xu, C.; Zou, L.; Scott, K.; Liu, J. A polytetrafluoroethylene porous membrane and dimethylhexadecylamine quaternized poly(vinyl benzyl chloride) composite membrane for intermediate temperature fuel cells. J. Power Sources 2015, 294, 691–695.

Guenet, J. M.; Parmentier, J.; Daniel, C. Porous materials from polyvinylidene fluoride/solvent molecular compounds. Soft Mater. 2011, 9, 280–294.

Grishin, A. N.; Gutkovich, S. A. Influence of polymerisation conditions on the porosity of suspension polyvinyl chloride (PVC). Int. Polym. Sci. Technol. 2005, 32, 52–54.

Costa, C. M.; Lee, Y.; Kim, J.; Lee, S.; Lanceros-Méndez, S. Recent advances on separator membranes for lithium-ion battery applications: from porous membranes to solid electrolytes. Energy Storage Mater. 2019, 22, 346–375.

Waqas, M.; Ali, S.; Feng, C.; Chen, D.; Han, J.; He, W. Recent development in separators for high-temperature lithium-ion batteries. Small 2019, 15, 1901689.

Dai, J.; Shi, C.; Li, C.; Shen, X.; Peng, L.; Wu, D.; Sun, D.; Zhang, P.; Zhao, J. A rational design of separator with substantially enhanced thermal features for lithium-ion batteries by the polydopamine–ceramic composite modification of polyolefin membranes. Energy Environ. Sci. 2016, 9, 3252–3261.

Siegmann, A.; Raiter, I.; Narkis, M.; Eyerer, P. Effect of powder particle morphology on the sintering behaviour of polymers. J. Mater. Sci. 1986, 21, 1180–1186.

Barnetson, A.; Hornsby, P. R. Observations on the sintering of ultra-high molecular weight polyethylene (UHMWPE) powders, J. Mater. Sci. Lett. 1995, 14, 80–84.

Pal, K.; Bag, S.; Pal, S. Development of porous ultra-high molecular weight polyethylene scaffolds for the fabrication of orbital implant. J. Porous Mater. 2008, 15, 53–59.

Plumlee, K.; Schwartz, C. J. Development of porous UHMWPE morphologies for fixation of gel-based materials. J. Appl. Polym. Sci. 2009, 114, 2555–2563.

Pal, K.; Bag, S.; Pal, S. Development and coating of porous ultrahigh molecular weight polyethylene plates. Trends in Biomater. Artificial Organs 2005, 19, 39–45.

Li, L.; de Jeu, W. H. Shear-induced smectic ordering in the melt of isotactic polypropylene. Phys. Rev. Lett. 2004, 92, 075506.

Hu, W.; Frenkel, D.; Mathot, V. B. F. Simulation of shish-kebab crystallite induced by a single prealigned macromolecule. Macromolecules 2002, 5, 7172–7174.

Pennings, A. J.; van der Mark, J. M. A. A.; Kiel, A. M. Hydrodynamically induced crystallization of polymers from solution. Kolloid-Zeitschrift und Zeitschrift für Polymere 1970, 237, 336–358.

Bashir, Z.; Odell, J. A.; Keller, A. High modulus filaments of polyethylene with lamellar structure by melt processing; the role of the high molecular weight component. J. Mater. Sci. 1984, 19, 3713–3725.

Bashir, Z.; Odell, J. A.; Keller, A. Stiff and strong polyethylene with shish kebab morphology by continuous melt extrusion. J. Mater. Sci. 1986, 21, 3993–4002.

Keum, J. K.; Zuo, F.; Hsiao, B. S. Formation and stability of shear-induced shish-kebab structure in highly entangled melts of UHMWPE/HDPE blends. Macromolecules 2008, 41, 4766–4776.

Zhao, C.; He, J.; Li, J.; Tong, J.; Xiong, J. Preparation and properties of UHMWPE microporous membrane for lithium ion battery diaphragm. IOP Conf. Ser. Mater. Sci. Eng. 2018, 324, 012089.

Li, J.; Li, R.; Gu, Q.; Zhang, Q.; Yu, T. X.; Gao, P. Flexible ultra strong 100-nm polyethylene membranes with polygonal pore structures. Appl. Phys. 2019.

Geng, L.; Li, L.; Mi, H.; Chen, B.; Sharma, P.; Ma, H.; Hsiao, B. S.; Peng, X.; Kuang, T. Superior impact toughness and excellent storage modulus of poly(lactic acid) foams reinforced by shish-kebab nanoporous structure. ACS Appl. Mater. Interfaces 2017, 9, 21071–21076.

Li, L.; Li, W.; Geng, L.; Chen, B.; Mi, H.; Hong, K.; Peng, X.; Kuang, T. Formation of stretched fibrils and nanohybrid shish-kebabs in isotactic polypropylene-based nanocomposites by application of a dynamic oscillatory shear. Chem. Eng. J. 2018, 348, 546–556.

Wang, Z.; Mao, Y.; Li, X.; Li, Y.; Jarumaneeroj, C.; Thitisak, B.; Tiyapiboonchaiya, P.; Rungswang, W; S. Hsiao, B. S. The influence of ethyl branch on formation of shish-kebab crystals in bimodal polyethylene under shear at low temperature. Chinese. J. Polym. Sci. 2021, 39, 1050–1058.

Kovalenko, A.; Zimny, K.; Mascaro, B.; Brunet, T.; Mondain-Monval, O. Tailoring of the porous structure of soft emulsion-templated polymer materials. Soft Matter 2016, 12, 5154–5163.

Martina, A. D.; Hilborn, J. G.; Kiefer, J.; Hedrick, J. L.; Srinivasan, S.; Miller, R. D. Siloxane elastomer foams. ACS Symposium Series. Washington, DC: American Chemical Society 1997, 669, 8–25. https://doi.org/10.1021/bk-1997-0669.ch002

Jin, Y.; Kumar, R.; Poncelet, O.; Mondain-Monval, O.; Brunet, T. Flat acoustics with soft gradient-index metasurfaces. Nat. Commun. 2019, 10, 143–149.

Pennings, A. J.; Kiel, A. M. Fractionation of polymers by crystallization from solution, III. On the morphology of fibrillar polyethylene crystals grown in solution. Kolloid-Zeitschrift Und Zeitschrift Für Polym. 1965, 205, 160–162.

Lermontov, S. A.; Maksimkin, A. V.; Sipyagina, N. A.; Malkova, A. N.; Kolesnikov, E. A.; Zadorozhnyy, M. Y.; Straumal, E. A.; Dayyoub, T. Ultra-high molecular weight polyethylene with hybrid porous structure. Polymer 2020, 202, 122744.

Lermontov, S. A.; Malkova, A. N.; Sipyagina, N. A.; Straumal, E. A.; Maksimkin, A. V.; Kolesnikov, E. A.; Senatov, F. S. Properties of highly porous aerogels prepared from ultra-high molecular weight polyethylene. Polymer 2019, 182, 121824.

Maksimkin, A. V.; Kharitonov, A. P.; Nematulloev, S. G.; Kaloshkin, S. D.; Gorshenkov, M. V.; Chukov, D. I.; Shchetinin, I. V. Fabrication of oriented UHMWPE films using low solvent concentration. Mater. Des. 2017, 115, 133–137.

Dayyoub, T.; Maksimkin, A.V.; Kaloshkin, S.; Kolesnikov, E.; Chukov, D.; Dyachkova, T.P.; Gutnik, I. The structure and mechanical properties of the UHMWPE films modified by the mixture of graphene nanoplates with polyaniline. Polymers 2019, 11, 23.

Hoffman, J. D.; Frolen, L. J.; Ross, G. S.; Lauritzen, J. I. On the growth rate of spherulites and axialites from the melt in polyethylene fractions: regime I and regime II crystallization. J. Res. Natl. Bureau Stand. Sect. A 1975, 79A, 671.

Talebi, S.; Duchateau, R.; Rastogi, S.; Kaschta, J.; Peters, G. W. M.; Lemstra, P. J. Molar mass and molecular weight distribution determination of UHMWPE synthesized using a living homogeneous catalyst. Macromolecules 2010, 43, 2780–2788.

Liu, K. J.; Zhang, J.; Liu, H.; Qian, X. Y.; Zhang, Y.; Wang, T.; Shen, K. Z. A multi-layer bioinspired design with evolution of shish-kebab structures induced by controlled periodical shear field. Express Polym. Lett. 2013, 7, 355–364.

Yi, L.; Luo, S.; Shen, J.; Guo, S.; Sue, H. J. Bioinspired polylactide based on the multilayer assembly of shish-kebab structure: a strategy for achieving balanced performances. ACS Sustainable Chem. Eng. 2017, 5, 3063–3073.

Nitta, K. H. On the orientation-induced crystallization of polymers. Polymers 2016, 8, 229.

Kumaraswamy, G. Crystallization of polymers from stressed melts. J. Macromol. Sci. C 2005, 45, 375–397.

An, M.; Xu, H.; Lv, Y.; Tian, F.; Gu, Q.; Wang, Z. The effect of chitin nanocrystal on the structural transition of shish-kebab to fibrillar crystals of ultra-high molecular weight polyethylene/chitin nanocrystal fibers during hot-stretching process. Eur. Polym. J. 2017, 96, 463–473.

Strobl, G. Colloquium: laws controlling crystallization and melting in bulk polymers. Rev. Mod. Phys. 2009, 81, 1287–1300.

Somani, R. H.; Yang, L.; Zhu, L.; Hsiao, B. S. Flow-induced shishkebab precursor structures in entangled polymer melts. Polymer 2005, 46, 8587–8623.

Wang, Z.; Mao, Y.; Jarumaneeroj, C.; Thitisak, B.; Tiyapiboonchaiya, P.; Rungswang, W.; Hsiao, B. S. The influence of short chain branch on formation of shish-kebab crystals in bimodal polyethylene under shear at high temperatures. J. Polym. Sci., Part B: Polym. Phys. 2018, 56, 786–79.

Zhao, R.; Chu, Z.; Ma, Z. Flow-induced crystallization in polyethylene: effect of flow time on development of shish-kebab. Polymers 2020, 12, 2571.

Zuo, F.; Keum, J.; Yang, L.; Somani, R. H.; Hsiao, B. S. Thermal stability of shear-induced shish-kebab precursor structure from high molecular weight polyethylene chains. Macromolecules 2006, 39, 2209–2218.

Jeon, M. Y.; Kim, C. K. Phase behavior of polymer/diluent/diluent mixtures and their application to control microporous membrane structure. J. Membr. Sci. 2007, 300, 172–181.

Flaim, T. D.; Wang, Y.; Mercado, R. High-refractive-index polymer coatings for optoelectronics applications. Advances in Optical Thin Films 2004, 1–12. Doi:https://doi.org/10.1117/12.513363.

Acknowledgments

This work was financially supported by the Academic leadership program Priority 2030 proposed by Federal State Autonomous Educational Institution of Higher Education I.M. Sechenov First Moscow State Medical University of the Ministry of Health of the Russian Federation (Sechenov University). The preparation and modification of UHMWPE samples were financially supported by the Russian Science Foundation (No. 18-13-00145), SEM investigation was supported by the State Assignment (No. 0090-2019-0002, IPAC RAS).

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

The authors declare no interest conflict.

Rights and permissions

About this article

Cite this article

Lermontov, S.A., Maksimkin, A.V., Sipyagina, N.A. et al. Porous Shish-Kebab Structure Prepared from Oriented UHMWPE Films by Processing in Supercritical CO2. Chin J Polym Sci 42, 97–104 (2024). https://doi.org/10.1007/s10118-023-3036-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10118-023-3036-x