Abstract

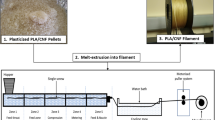

Incorporation of nanoparticles into polymer blend to obtain finely dispersed morphology has been considered as an effective strategy to prepare nanocomposites. Owing to the renewable and degradable characters, cellulose nanocrystals (CNCs) have been proposed to tailor the phase morphology of poly(L-lactic acid) (PLLA) blend for producing high-performance fused deposition modeling (FDM) consumables. However, the main challenge associated with the ternary systems is the dispersion of the highly hydrophilic CNCs in non-polar PLLA blend by industrial melt blending without involving solution. Herein, with poly(vinyl acetate) (PVAc) modified CNCs powder (a mixture of PVAc grafted from CNCs and PVAc homopolymer latex), the selective dispersion of CNCs in PLLA has been achieved by simple melt processing of PLLA/TPU (polyether polyurethane)/CNCs blend. This results in the ultra-fine TPU droplets at nanoscale in PLLA and improves the melt processibility of composites in FDM due to the decreased viscosity ratio of the dispersed/matrix and the enhanced melt elasticity of PLLA. Combined with the intensive shear and continuous stretch effect during FDM, aligned TPU nanofibers (TNFs) were in situ formed along the elongational flow direction during deposition, which in turn contributed to the improvement of PLLA/TPU/CNCs with 5 wt% filler loading in tensile ductility by 418%, inter-layer adhesion strength and notched impact toughness by 261% and 210%, respectively, as well as achieved good dimensional accuracy and very fine surface quality.

Similar content being viewed by others

References

Goh, G. D.; Yap, Y. L.; Tan, H. K. J.; Sing, S. L.; Goh, G. L.; Yeong, W. Y. Process-structure-properties in polymer additive manufacturing via material extrusion: a review. Crit. Rev. Solid. State. 2019, 45, 113–133.

Wasti, S.; Adhikari, S. Use of biomaterials for 3D printing by fused deposition modeling technique: a review. Front. Chem. 2020, 8, 315.

Lim, L. T.; Auras, R.; Rubino, M. Processing technologies for poly(lactic acid). Prog. Polym. Sci. 2008, 33, 820–852.

Liu, Z.; Wang, Y.; Wu, B.; Cui, C.; Guo, Y.; Yan, C. A critical review of fused deposition modeling 3D printing technology in manufacturing polylactic acid parts. Int. J. Adv. Manuf. Tech. 2019, 102, 2877–2889.

Nofar, M.; Salehiyan, R.; Sinha Ray, S. Rheology of poly(lactic acid)-based systems. Polym. Rev. 2019, 59, 465–509.

Jašo, V.; Cvetinov, M.; Rakić, S.; Petrović, Z. S. Bio-plastics and elastomers from polylactic acid/thermoplastic polyurethane blends. J. Appl. Polym. Sci. 2014, 131, 41104.

Wu, M.; Wu, Z.; Wang, K.; Zhang, Q.; Fu, Q. Simultaneous the thermodynamics favorable compatibility and morphology to achieve excellent comprehensive mechanics in PLA/OBC blend. Polymer 2014, 55, 6409–6417.

Xu, C.; Yuan, D.; Fu, L.; Chen, Y. Physical blend of PLA/NR with co-continuous phase structure: preparation, rheology property, mechanical properties and morphology. Polym. Test. 2014, 37, 94–101.

Nofar, M.; Sacligil, D.; Carreau, P. J.; Kamal, M. R.; Heuzey, M. C. Poly(lactic acid) blends: processing, properties and applications. Int. J. Biol. Macromol. 2019, 125, 307–360.

Yu, F.; Huang, H. X. Simultaneously toughening and reinforcing poly(lactic acid)/thermoplastic polyurethane blend via enhancing interfacial adhesion by hydrophobic silica nanoparticles. Polym. Test. 2015, 45, 107–113.

Sumita, M.; Sakata, K.; Asai, S.; Miyasaka, K.; Nakagawa, H. Dispersion of fillers and the electrical conductivity of polymer blends filled with carbon black. Polym. Bull. 1991, 25, 265–271.

Göldel, A.; Marmur, A.; Kasaliwal, G. R.; Pötschke, P.; Heinrich, G. Shape-dependent localization of carbon nanotubes and carbon black in an immiscible polymer blend during melt mixing. Macromolecules 2011, 44, 6094–6102.

Jalali Dil, E.; Favis, B. D. Localization of micro- and nano-silica particles in heterophase poly(lactic acid)/poly(butylene adipate-co-terephthalate) blends. Polymer 2015, 76, 295–306.

Eichhorn, S. J.; Dufresne, A.; Aranguren, M.; Marcovich, N. E.; Capadona, J. R.; Rowan, S. J.; Weder, C.; Thielemans, W.; Roman, M.; Renneckar, S.; Gindl, W.; Veigel, S.; Keckes, J.; Yano, H.; Abe, K.; Nogi, M.; Nakagaito, A. N.; Mangalam, A.; Simonsen, J.; Benight, A. S.; Bismarck, A.; Berglund, L. A.; Peijs, T. Review: current international research into cellulose nanofibres and nanocomposites. J. Mater. Sci. 2010, 45, 1–33.

Bitinis, N.; Verdejo, R.; Bras, J.; Fortunati, E.; Kenny, J. M.; Torre, L.; Lopez-Manchado, M. A. Poly(lactic acid)/natural rubber/cellulose nanocrystal bionanocomposites part I. Processing and morphology. Carbohydr. Polym. 2013, 96, 611–620.

Arrieta, M. P.; Fortunati, E.; Dominici, F.; Rayon, E.; Lopez, J.; Kenny, J. M. Multifunctional PLA-PHB/cellulose nanocrystal films: processing, structural and thermal properties. Carbohydr. Polym. 2014, 107, 16–24.

Heshmati, V.; Kamal, M. R.; Favis, B. D. Tuning the localization of finely dispersed cellulose nanocrystal in poly(lactic acid)/bio-polyamide11 blends. J. Polym. Sci., Part B: Polym. Phys. 2018, 56, 576–587.

Liu, Y.; Lu, Y.; Zhang, H.; Liu, X.; Kong, Z.; Zhou, L.; Liu, H.; Zhang, J. Polymer grafting on cellulose nanocrystals initiated by ceric ammonium nitrate: is it feasible under acid-free conditions? Green Chem. 2021, https://doi.org/10.1039/D1GC03142B.

Liu, Y.; Liu, L.; Wang, K.; Zhang, H.; Yuan, Y.; Wei, H.; Wang, X.; Duan, Y.; Zhou, L.; Zhang, J. Modified ammonium persulfate oxidations for efficient preparation of carboxylated cellulose nanocrystals. Carbohydr. Polym. 2020, 229, 115572.

Oliaei, E.; Kaffashi, B.; Davoodi, S. Investigation of structure and mechanical properties of toughened poly(L-lactide)/thermoplastic poly (ester urethane) blends. J. Appl. Polym. Sci. 2016, 133(15), 43104.

Pracella, M.; Haque, M. M. U.; Puglia, D. Morphology and properties tuning of PLA/cellulose nanocrystals bio-nanocomposites by means of reactive functionalization and blending with PVAc. Polymer 2014, 55, 3720–3728.

Dufresne, A. Cellulose nanomaterials as green nanoreinforcements for polymer nanocomposites. Philos. Trans. A Math. Phys. Eng. Sci. 2018, 376, 0040.

Le Corroller, P.; Favis, B. D. Effect of viscosity in ternary polymer blends displaying partial wetting phenomena. Polymer 2011, 52, 3827–3834.

Nuzzo, A.; Coiai, S.; Carroccio, S. C.; Dintcheva, N. T.; Gambarotti, C.; Filippone, G. Heat-resistant fully bio-based nanocomposite blends based on poly(lactic acid). Macromol. Mater. Eng. 2014, 299, 31–40.

Elias, L.; Fenouillot, F.; Majeste, J. C.; Cassagnau, P. Morphology and rheology of immiscible polymer blends filled with silica nanoparticles. Polymer 2007, 48, 6029–6040.

Krasovitski, B.; Marmur, A. Particle adhesion to drops. J. Adhes. 2007, 81, 869–880.

Yu, G.; Zhang, M.; Zeng, H.; Hou, Y.; Zhang, H. Effect of filler treatment on temperature dependence of resistivity of carbon-black-filled polymer blends. J. Appl. Polym. Sci. 1999, 73, 489–494.

Owens, D. Estimation of the surface free energy of polymers. J. Appl. Polym. Sci. 1969, 13, 1741–1747.

Vatansever, E.; Arslan, D.; Nofar, M. Polylactide cellulose-based nanocomposites. Int. J. Biol. Macromol. 2019, 137, 912–938.

Chen, G.; Chen, N.; Wang, Q. Preparation of poly(vinyl alcohol)/ionic liquid composites with improved processability and electrical conductivity for fused deposition modeling. Mater. Design. 2018, 157, 273–283.

Heshmati, V.; Kamal, M. R.; Favis, B. D. Cellulose nanocrystal in poly(lactic acid)/polyamide11 blends: preparation, morphology and co-continuity. Eur. Polym. J. 2018, 98, 11–20.

Ou-Yang, Q.; Guo, B.; Xu, J. Preparation and characterization of poly (butylene succinate)/polylactide blends for fused deposition modeling 3D printing. ACS Omega 2018, 3, 14309–14317.

Wickramasinghe, S.; Do, T.; Tran, P. FDM-based 3D printing of polymer and associated composite: a review on mechanical properties, defects and treatments. Polymers 2020, 12, 1529.

Ertan, R.; Durgun, I. Experimental investigation of FDM process for improvement of mechanical properties and production cost. Rapid Prototyping J. 2014, 20, 228–235.

Jiang, Y.; Leng, J.; Zhang, J. A high-efficiency way to improve the shape memory property of 4D-printed polyurethane/polylactide composite by forming in situ microfibers during extrusion-based additive manufacturing. Addit. Manuf. 2021, 38, 101718.

Zhang, X; Wang, J. Controllable interfacial adhesion behaviors of polymer-on-polymer surfaces during fused deposition modeling 3D printing process. Chem. Phys. Lett. 2020, 739, 136959.

Zhang, X.; Fan, W.; Liu, T. Fused deposition modeling 3D printing of polyamide-based composites and its applications. Compos. Commun. 2020, 21, 100413.

Doddamani, M. Dynamic mechanical analysis of 3D printed ecofriendly lightweight composite. Compos. Commun. 2020, 19, 177–181.

Mishra, P.; Senthil, P.; Adarsh, S.; Anoop, M. An investigation to study the combined effect of different infill pattern and infill density on the impact strength of 3D printed polylactic acid parts. Compos. Commun. 2021, 24, 100605.

Dave, H.; Patadiya, N.; Prajapati, A.; Rajpurohi, S. Effect of infill pattern and infill density at varying part orientation on tensile properties of fused deposition modelling printed poly-lactic acid part. J. Mechan. Eng. Sci. 2021, DOI: https://doi.org/10.1177/0954406219856383.

Qattawi, A.; Alrawi, B.; Guzman, A. Experimental optimization of fused deposition modelling processing parameters: a design-for-manufacturing approach. Procedia Manuf. 2017, 10, 791–803.

Acknowledgments

The authors acknowledge the financial support from the National Natural Science Foundation of China (Nos. 21774068, 51503782) and Key Research and Development Program of Shaanxi Province of China (No. 2021GY-236).

Author information

Authors and Affiliations

Corresponding author

Additional information

Notes

The authors declare no competing financial interest.

Electronic Supplementary Information

Rights and permissions

About this article

Cite this article

Wu, X., Liu, YX., Wu, HP. et al. Cellulose Nanocrystals-mediated Phase Morphology of PLLA/TPU Blends for 3D Printing. Chin J Polym Sci 40, 299–309 (2022). https://doi.org/10.1007/s10118-022-2665-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10118-022-2665-9