Abstract

To meet the processing requirements of resin transfer moulding (RTM) technology, reactive diluent containing m-phenylene moiety was synthesized to physically mixed with phenylethynyl terminated cooligoimides with well-designed molecular weights of 1500–2500 g/mol derived from 4,4′-(hexafluoroisopropylidene)diphthalic anhydride (6FDA), 3,4′-oxydianiline (3,4′-ODA) and m-phenylenediamine (m-PDA). This blend shows low minimum melting viscosity (<1 Pa·s) and enlarged processing temperature window (260–361 °C). FPI-R-1 stays below 1 Pa·s for 2 h at 270 °C. The relationship between the molecular weight of the blend and its melting stability was first explored. Blending oligoimides with lower molecular weights exhibit better melting stability. Upon curing at 380 °C for 2 h, the thermosetting polyimide resin demonstrates superior heat resistance (Tg=420–426 °C).

Similar content being viewed by others

References

Smith, J. G.; Connell, J. W.; Hergenrother, P. M. The effect of phenylethynyl terminated imide oligomer molecular weight on the properties of composites. J. Compos Mater. 2000, 34, 614–628.

Mangalgiri, P. D. Polymer-matrix composites for high-temperature applications. Def. Sci. J. 2005, 55, 175–193.

Connell, J. W.; Smith, J. G.; Hergenrother, P. M. Oligomers and polymers containing phenylethynyl groups. J. Macromol. Sci.: Polym. Rev. 2000, 40, 207–230.

Chuang, K. C.; Bowles, K. J.; Papadopoulos, D.; Hardy-Green, D.; McCorkle, L. A high Tg PMR polyimide composites (DMBZ-15). J. Adv. Mater. 2001, 33, 33–38.

Serafini, T. T. Delvigs, P.; Lightsey, G. R. Thermally stable polyimides from solutions of monomeric reactants. J. Appl. Polym. Sci. 1972, 16, 905–915.

Vannucci, R. D.; Cifani, D. The 700 F Properties of Autoclave Cured PMR-2, NASA-TM-100923 1988.

Wang, Z. H.; Fang, G. Q.; He, J. J.; Yang, H. X.; Yang, S. Y. Semi-aromatic thermosetting polyimide resins containing alicyclic units for achieving low melt viscosity and low dielectric constant. React. Funct. Polym. 2020, 146, 104411.

Cho, D.; Drzal, L. T. Phenylethynyl-terminated polyimide, exfoliated graphite nanoplatelets, and the composites: an overview. Carbon Lett. 2016, 19, 1–11.

Liaw, D. J.; Wang, K. L.; Huang, Y. C.; Lee, K. R.; Lai, J. Y.; Ha, C. S. Advanced polyimide materials: syntheses, physical properties and applications. Prog. Polym. Sci. 2012, 37, 907–974.

Yu, P.; Wang, Y.; Yu, J. R.; Zhu, J.; Hu, Z. M. Synthesis and characterization of phenylethynyl-terminated polyimide oligomers derived from 2,3,3′,4′-diphenyl ether tetracarboxylic acid dianhydride and 3,4’-oxydianiline. Chinese J. Polym. Sci. 2016, 34, 122–134.

Simone, C. D.; Scola, D. A. Modification of PETI-5K imide oligomers: effect on viscosity. High Perform. Polym. 2003, 15, 473–501.

Cho, D.; Drzal, L. T. Characterization, properties, and processing of LaRC PETI-5 as a high-temperature sizing material. II. Thermal characterization. J. Appl. Polym. Sci. 2000, 75, 1278–1287.

Ogasawara, T.; Ishida, Y.; Yokota, R.; Watanabe, T.; Aoi, T.; Goto, J. Processing and properties of carbon fiber/triple-A polyimide composites fabricated from imide oligomer dry prepreg. Compos. Pt. A-Appl. Sci. Manuf. 2007, 38, 1296–1303.

Yokota, R.; Yamamoto, S.; Yano, S.; Sawaguchi, T.; Hasegawa, M.; Yamaguchi, H.; Ozawa, H.; Sato, R. Molecular design of heat resistant polyimides having excellent processability and high glass transition temperature. High Perform. Polym. 2016, 13, S61–S72.

Ogasawara, T.; Ishikawa, T.; Yokota, R.; Ozawa, H.; Taguchi, M.; Sato, R.; Shigenari, Y.; Miyagawa, K. Processing and properties of carbon fiber reinforced triple-A polyimide (Tri-A PI) matrix composites. Adv. Compos. Mater. 2002, 11, 277–286.

Cho, D.; Drzal, L. T. Characterization, properties, and processing of LaRC™ PETI-5 as a high-temperature sizing material. I. FTIR studies on imidization and phenylethynyl end-group reaction behavior. J. Appl. Polym. Sci. 2000, 76, 190–200.

Fang, X.; Rogers, D. F.; Scola, D. A.; Stevens, M. P. A study of the thermal cure of a phenylethynyl-terminated imide model compound and a phenylethynyl-terminated imide oligomer (PETI-5). J. Polym. Sci., Part A: Polym. Chem. 1998, 36, 461–470.

Li, Y.; Morgan, R. J. Thermal cure of phenylethynyl-terminated AFR-PEPA-4 imide oligomer and a model compound. J. Appl. Polym. Sci. 2006, 101, 4446–4453.

Fang, X.; Xie, X. Q.; Simone, C. D.; Stevens, M. P.; Scola, D. A. A solid-state 13C NMR study of the cure of 13C-labeled phenylethynyl end-capped polyimides. Macromolecules. 2000, 33, 1671–1681.

Zhang, Y.; Jain, A.; Grunenfelder, L. K.; Miyauchi, M.; Nutt, S. Process development for phenylethynyl-terminated PMDA-type asymmetric polyimide composites. High Perform. Polym. 2017, 30, 731–741.

Cho, D.; Choi, Y.; Drzal, L. T. Simultaneous monitoring of the imidization and cure reactions of LaRC PETI-5 sized on a braided glass fabric substrate by dynamic mechanical analysis. Polymer 2001, 42, 4611–4618.

Hong, W.; Yuan, L.; Ma, Y.; Cui, C.; Zhang, H.; Yang, S. Y.; Sun, W. H. Resin transfer moldable fluorinated phenylethynyl-terminated imide oligomers with high Tg: structure-melt stability relationship. Polymers 2021, 13, 903–925.

Su, C. N.; Ji, M.; Fan, L.; Yang, S. Y. Phenyl-endcapped oligoimides with low melt viscosities and high Tgs: effects of the molecular weights. High Perform. Polym. 2011, 23, 352–361.

Fu, X.; Zhang, C.; Liang, R.; Wang, B.; Fielding, J. C. High temperature vacuum assisted resin transfer molding of phenylethynyl terminated imide composites. Polym. Compos. 2010, 32, 52–58.

Kejian, W.; Ogasawara, T.; Ishida, Y. Optimization of liquid molding cycle for a phenylethynyl terminated polyimide composite. J. Reinf. Plast. Compos. 2005, 25, 361–377.

Smith, J. J. G.; Connell, J. W.; Hergenrother, P. M.; Criss, J. M. Resin teansfer moldable phenylethynyl containing imide oligomers. J. Compos. Mater. 2002, 36, 2255–2265.

Connell, J. W.; Smith, J. G.; Hergenrother, Jr., P. M.; Criss, J. M. High temperature transfer molding resins: status of PETI-298 and PETI-330. NASA Langley Research Center; Hampton, VA, United States, 2003.

Smith, J. G.; Connell, J. W.; Hergenrother, P. M.; Ford, L. A.; Criss, J. M. Transfer molding imide resins based on 2,3,3′,4′- biphenyltetracarboxylic dianhydride. Macromol. Symp. 2003, 199, 401–418.

Connell, J. W.; Smith, J. G.; Hergenrother, Jr. P. M.; Criss, J. M.; High temperature transfer molding resins: preliminary composite properties of PETI-375. NASA Langley Research Center, Hampton, VA, United States, 2004.

Meng, X.; Zheng, Y.; Yan, J.; Li, Y.; Wang, Z.; Li, G. 2, 3, 3′, 4′-Oxydiphthalic dianhydride-based phenylethynyl-terminated imide oligomers for low-temperature resin transfer molding applications. High Perform. Polym. 2016, 28, 962–970.

Chuang, K. C.; Criss, J. M.; Mintz, E. A. Polyimides based on asymmetric dianhydrides (ii) (a-BPDA vs a-BTDA) for resin transfer molding (RTM). NASA Glenn Research Center; Cleveland, OH, United States Air Force Office of Scientific Research, Bolling AFB; Washington, DC, United States 2010.

Miyauchi, M.; Ishida, Y.; Ogasawara, T.; Yokota, R. Novel phenylethynyl-terminated PMDA-type polyimides based on KAPTON backbone structures derived from 2-phenyl-4,4′- diaminodiphenyl ether. Polym. J. 2012, 44, 959–965.

Wang, W.; Chen, G.; Fang, X. 1,4-Bis(2,3-dicarboxylphenoxy)benzene dianhydride-based phenylethynyl terminated thermoset oligoimides for resin transfer molding applications. J. Appl. Polym. Sci. 2019, 136, 47967.

Connell, J. W.; Smith, J. G.; Hergenrother, P. M.; Rommel, M. L. Neat resin, adhesive and composite properties of reactive additive/PETI-5 Blends. High Perform. Polym. 2000, 12, 323–333.

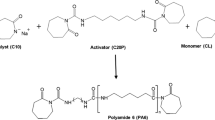

Liu, H. B.; Simone, C. D.; Scola, D. A. Synthesis and characterization of phenylethynyl-end-capped cooligomides from fluorinated dianhydrides 4,4′-(hexafluoroisopropylidene)dipthalic anhydride and 4,4′-(2,2,2- trifluoro-1-phenylethylidene)dipthalic anhydride and para- and meta-phenylene diamines and cooligomide blends with phenylethynyl-end-capped reactive diluents. J. Polym. Sci., Part A: Polym. Chem. 2003, 41, 2630–2649.

Liu, H.; Simone, C. D.; Katiyar, P. S.; Scola, D. A. Adhesive properties of low-viscosity phenylethynyl (PE) end-capped co-oligomides and co-oligomide blends. Int. J. Adhes. Adhes. 2005, 25, 219–226.

Rao, X.; Dang, G.; Zhou, H.; Yang, W.; Cui, G.; Chen, C.; Yokota, R. Design and synthesis of a tribranched phenylethynyl-terminated aryl ether compound and its use as a reactive diluent for PETI-5. J. Polym. Sci., Part A: Polym. Chem. 2007, 45, 4844–4854.

Yu, P.; Wang, Y.; Yu, J.; Zhu, J.; Hu, Z. Development of novel cardo-containing phenylethynyl-terminated polyimide with high thermal properties. Polym. Adv. Technol. 2017, 28, 222–232.

Yue, J.; Li, Y.; Zhao, Y.; Xiang, D.; Dai, Y. Thermal degradation behavior of carborane-containing phenylethynyl terminated imide systems. Polym. Degrad. Stabil. 2016, 129, 286–295.

Wu, Y.; Yang, J.; Chen, G. Synthesis and characterization of a carborane-containing monofunctional imide monomer as a modifier for imide oligomer. High Perform. Polym. 2017, 30, 812–820.

Zhou, D.; Yuan, L.; Hong, W.; Zhang, H.; Hu, A.; Yang, S. Molecular design of interpenetrating fluorinated polyimide network with enhanced high performance for heat-resistant matrix. Polymer 2019, 173, 66–79.

Liu, Y.; Mo, S.; He, M.; Zhai, L.; Xu, C.; Fan, L. Phenylethynyl-terminated oligoimides based on bis(p-aminophenoxy)dimethyl silane: effect of siloxane structure on processability and thermal stability. High Perform. Polym. 2018, 31, 651–661.

Rao, X.; Zhou, H; Dang, G.; Chen, C.; Wu, Z. New kinds of phenylethynyl-terminated polyimide oligomers with low viscosity and good hydrolytic stability. Polymer 2006, 47, 6091–6098.

Srinivas, S.; Caputo, F. E.; Graham, M.; Gardner, S.; Davis, R. M.; McGrath, J. E.; Wilkes, G. L. Semicrystalline polyimides based on controlled molecular weight phthalimide end-capped 1,3-bis(4-aminophenoxy)benzene and 3,3′,4,4′-biphenyltetracarboxylic dianhydride: synthesis, crystallization, melting, and thermal stability. Macromolecules 1997, 30, 1012–1022.

Ratta, V.; Ayambem, A.; McGrath, J. E.; Wilkes, G. L. Crystallization and multiple melting behavior of a new semicrystalline polyimide based on 1,3-bis(4-aminophenoxy)benzene (TPER) and 3,3′,4,4′-biphenonetetracarboxylic dianhydride (BTDA). Polymer 2001, 42, 6173–6186.

Wu, X.; Yang, X.; Yu, R.; Zhao, X. J.; Zhang, Y.; Huang, W. Highly crosslinked and uniform thermoset epoxy microspheres: preparation and toughening study. Polymer 2018, 143, 145–154.

Zheng, S.; Mi, Y. Miscibility and intermolecular specific interactions in blends of poly(hydroxyether of bisphenol A) and poly(4-vinyl pyridine). Polymer 2003, 44, 1067–1074.

Gupta, R. K., in Polymer and Composite Rheology, second edition, Marcel Dekker Inc. New York 2000, p. 58.

Zhuang, Y.; Seong, J. G.; Do, Y. S.; Jo, H. J.; Lee, M. J.; Wang, G.; Guiver, M. D.; Lee, Y. M. Effect of isomerism on molecular packing and gas transport properties of poly(benzoxazole-co-imide)s. Macromolecules 2014, 47, 7947–7957.

Santiago-García, J. L.; Álvarez, C.; Sánchez, F.; de la Campa, J. G. Gas transport properties of new aromatic polyimides based on 3,8-diphenylpyrene-1,2,6,7-tetracarboxylic dianhydride. J. Membr. Sci. 2015, 476, 442–448.

Borek, J.; Osoba, W. The influence of the plasticization on free volume in polyvinyl chloride. J. Radioanal. Nucl. Chem. 1996, 211, 61–67.

Larocca, N. M.; Pessan, L. A. Effect of antiplasticisation on the volumetric, gas sorption and transport properties of polyetherimide. J. Membr. Sci. 2003, 218, 69–92.

Sharma, S. K.; Prakash, J.; Bahadur, J.; Sahu, M.; Mazumder, S.; Pujari, P. K. Free volume and lamellar structure of poly vinyl alcohol-nanosized BaTiO3 composite: positron annihilation and small angle X-ray scattering study. Eur. Polym. J. 2016, 84, 100–110.

Hrma, P. Arrhenius model for high-temperature glass-viscosity with a constant pre-exponential factor. J. Non-Cryst. Solids 2008, 354, 1962–1968.

Acierno, D.; Brancaccio, A.; Curto, D.; La Mantia, F. P.; Valenza, A. Molecular weight dependency of rheological characteristics of linear low density polyethylene. J. Rheol. 1985, 29, 323–334.

Mendelson, R. A. Melt viscosity behavior of some engineering thermoplastics. Polym. Eng. Sci. 1983, 23, 79–85.

Macho, E.; Alegría, A.; Colmenero, J. Determining viscosity temperature behavior of four amorphous thermoplastics using a parallel plate technique. Polym. Eng. Sci. 1987, 27, 810–815.

Yang, Y.; Fan, L.; Qu, X.; Ji, M.; Yang, S. Fluorinated phenylethynyl-terminated imide oligomers with reduced melt viscosity and enhanced melt stability. Polymer. 2011, 52, 138–148.

Liu, C.; Qu, C.; Wang, C.; Cao, D.; Wang, D.; Xiao, W.; Feng, H.; Liu, P.; Bai, X. Non-isothermal curing kinetics, chemorheological behaviour, and IR spectral study of two trifunctional phenylethynyl-terminated imide oligomers compared with the corresponding bifunctional structure. Prog. React. Kinet. Mech. 2019, 41, 1–13.

Zhang, D.; Wang, R.; Farhan, S.; Cai, Y.; Liu, J. Chemorheological behaviors of TDE-85 toughened by low viscosity liquid epoxy for RTM process. Polym. Test. 2018, 70, 310–319.

Roller, M. B. Characterization of the time-temperature-viscosity behavior of curing B-staged epoxy resin. Polym. Eng. Sci. 1975, 15, 406–414.

Stieghorst, J.; Doll, T. Rheological behavior of PDMS silicone rubber for 3D printing of medical implants. Addit. Manuf. 2018, 24, 217–223.

Bullions, T. A.; McGrath, J. E.; Loos, A. C. Development of a two-stage, dual-Arrhenius rheology model for a high-performance phenylethynyl-terminated poly(etherimide). Polym. Eng. Sci. 2002, 42, 2182–2192.

Teresa Rodríguez-Hernández, M.; Angulo-Sánchez, J. L.; Pérez-Chantaco, A. Determination of the molecular characteristics of commercial polyethylenes with different architectures and the relation with the melt flow index. J. Appl. Polym. Sci. 2007, 104, 1572–1578.

Kemblowski, Z.; Torzecki, J. Determination of the weight-average molecular-weight of polyamide-6 on the basis of melt viscosity. Rheol. Acta. 1983, 22, 186–196.

Lyu, M. Y.; Lee, J. S.; Pae, Y. Study of mechanical and rheological behaviors of linear and branched polycarbonates blends. J. Appl. Polym. Sci. 2001, 80, 1814–1824.

Langston, J. A.; Colby, R. H.; Chung, T. C. M.; Shimizu, F.; Suzuki, T.; Aoki, M. Synthesis and characterization of long chain branched isotactic polypropylene via metallocene catalyst and T-teagent. Macromolecules 2007, 40, 2712–2720.

Laius, L. A.; Dergacheva, Y. N.; Bessonov, M. I.; Koton, M. M. The nature of the higher thermal stability of rigid polyimides. Polymer Science U.S.S.R. 1984, 26, 1094–1102.

Acknowledgments

This work was financially supported by the National Natural Science Foundation of China (No. 51803222) and Science and Technology Service Network Initiative, Chinese Academy of Sciences.

Author information

Authors and Affiliations

Corresponding authors

Additional information

Notes

The authors declare no competing financial interest.

Electronic Supplementary Information

Rights and permissions

About this article

Cite this article

Hong, WJ., Yuan, LL., Zhang, HY. et al. Phenylethynyl-terminated Imide Oligomers Modified by Reactive Diluent for Resin Transfer Molding Application. Chin J Polym Sci 40, 107–120 (2022). https://doi.org/10.1007/s10118-021-2636-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10118-021-2636-6