Abstract

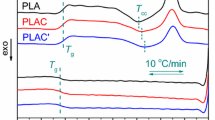

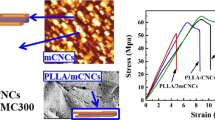

Incorporating the surface-grafted cellulose nanocrystals (CNCs) with enantiomeric polylactide (PLLA or PDLA) is an effective and sustainable way to modify PLLA, but their difference in promoting matrix crystallization is still unrevealed. In this study, the CNCs with identical content and length of PLLA and PDLA (CNC-g-L and CNC-g-D) were prepared and blended with PLLA. The rheological properties of PLLA/CNC-g-D are greatly improved, indicating that the stereocomplexation can significantly improve the interfacial strength as compared with the conventional van der Waals force in PLLA/CNC-g-L. Surprisingly, the matrix crystallizes at a higher rate in PLLA/CNC-g-L than PLLA/CNC-g-D. PLLA/CNC-g-L15 reaches its half crystallinity in 8.26 min while a longer period of 13.41 min is required for PLLA/CNC-g-D15. POM observation reveals that the superior crystallization behavior in PLLA/CNC-g-L is originated from its higher nucleation efficiency and faster growth rate. The formation of low content of sc-PLA at the interface can restrict the diffusion of PLLA but contribute less to generate crystalline nuclei, which synergistically leads to the retarded crystallization kinetics in PLLA/CNC-g-D. Revealing the mechanism of different interfacial enantiomeric grafting on the melt rheology and crystallization of PLLA is of great significance for the development of high-performance polylactide materials.

Similar content being viewed by others

References

Drumright, R. E.; Gruber, P. R.; Henton, D. E. Polylactic acid technology. Adv. Mater. 2000, 12, 1841–1846.

Wang, L.; Lee, R. E.; Wang, G.; Chu, R. K. M.; Zhao, J.; Park, C. B. Use of stereocomplex crystallites for fully-biobased microcellular low-density poly(lactic acid) foams for green packaging. Chem. Eng. J. 2017, 327, 1151–1162.

Nofar, M.; Ameli, A.; Park, C. B. Development of polylactide bead foams with double crystal melting peaks. Polymer 2015, 69, 83–94.

Nagarajan, V.; Mohanty, A. K.; Misra, M. Perspective on polylactic acid (PLA) based sustainable materials for durable applications: Focus on toughness and heat resistance. ACS Sustain. Chem. Eng. 2016, 4, 2899–2916.

Wang, Q. J.; Zhang, J.; Wang, X. H.; Wang, Z. G. Significant enhancement of notched Izod impact strength of PLA-based blends through encapsulating PA11 particles of low amounts by EGMA elastomer. Appl. Surf. Sci. 2020, 526, 146657.

Bai, J.; Fang, H.; Zhang, Y.; Wang, Z. Studies on crystallization kinetics of bimodal long chain branched polylactides. CrystEngComm 2014, 16, 2452–2461.

Li, C.; Luo, S.; Wang, J.; Wu, H.; Guo, S.; Zhang, X. Conformational regulation and crystalline manipulation of PLLA through a self-assembly nucleator. Biomacromolecules 2017, 18, 1440–1448.

Cheng, L.; Hu, C.; Li, J.; Huang, S.; Jiang, S. Stereocomplex-affected crystallization behaviour of PDLA in PDLA/PLDLA blends. CrystEngComm 2019, 21, 329–338.

Wang, B.; Wen, T.; Zhang, X.; Tercjak, A.; Dong, X.; Müller, A. J.; Wang, D.; Cavallo, D. Nucleation of poly(lactide) on the surface of different fibers. Macromolecules 2019, 52, 6274–6284.

Gong, X.; Pan, L.; Tang, C. Y.; Chen, L.; Li, C.; Wu, C.; Law, W. C.; Wang, X.; Tsui, C. P.; Xie, X. Investigating the crystallization behavior of poly(lactic acid) using CdSe/ZnS quantum dots as heterogeneous nucleating agents. Compos. Part B: Eng. 2016, 91, 103–110.

Sun, X.; Xue, B.; Yang, S. D.; Huo, K. W.; Liao, X. Y.; Li, X. J.; Xie, L.; Qin, S. H.; Zheng, Q. Structural conversion of PLLA/ZnO composites facilitated by interfacial crystallization to potential application in oil-water separation. Appl. Surf. Sci. 2020, 517, 146135.

Kulinski, Z.; Piorkowska, E. Crystallization, structure and properties of plasticized poly(L-lactide). Polymer 2005, 46, 10290–10300.

Okamoto, K.; Ichikawa, T.; Yokohara, T.; Yamaguchi, M. Miscibility, mechanical and thermal properties of poly(lactic acid)/polyesterdiol blends. Eur. Polym. J. 2009, 45, 2304–2312.

Dufresne, A. Cellulose nanomaterial reinforced polymer nanocomposites. Curr. Opin. Colloid. In. 2017, 29, 1–8.

Huang, S.; Zhou, L.; Li, M. C.; Wu, Q.; Zhou, D. Cellulose nanocrystals (CNCs) from corn stalk: activation energy analysis, Materials 2017, 80.

Qiu, Y.; Lv, Q.; Wu, D.; Xie, W.; Peng, S.; Lan, R.; Xie, H. Cyclic tensile properties of the polylactide nanocomposite foams containing cellulose nanocrystals. Cellulose 2018, 25, 1795–1807.

Tan, K.; Heo, S.; Foo, M.; Chew, I. M.; Yoo, C. An insight into nanocellulose as soft condensed matter: challenge and future prospective toward environmental sustainability. Sci. Total. Environ. 2019, 650, 1309–1326.

Matouk, Z.; Torriss, B.; Rincon, R.; Dorris, A.; Beck, S.; Berry, R. M.; Chaker, M. Functionalization of cellulose nanocrystal films using non-thermal atmospheric-Pressure plasmas. Appl. Surf. Sci. 2020, 511, 145566.

Zhou, L.; He, H.; Li, M.; Huang, S.; Mei, C.; Wu, Q. Enhancing mechanical properties of poly(lactic acid) through its in-situ crosslinking with maleic anhydride-modified cellulose nanocrystals from cottonseed hulls. Ind. Crop. Prod. 2018, 112, 449–459.

Yin, Y.; Lucia, L. A.; Pal, L.; Jiang, X.; Hubbe, M. A. Lipase-catalyzed laurate esterification of cellulose nanocrystals and their use as reinforcement in PLA composites. Cellulose 2020, 27, 6263–6273.

Shojaeiarani, J.; Bajwa, D. S.; Hartman, K. Esterified cellulose nanocrystals as reinforcement in poly(lactic acid) nanocomposites. Cellulose 2019, 26, 2349–2362.

Vatansever, E.; Arslan, D.; Nofar, M. Polylactide cellulose-based nanocomposites. Int. J. Biol. Macromol. 2019, 137, 912–938.

Bondeson, D.; Oksman, K. Dispersion and characteristics of surfactant modified cellulose whiskers nanocomposites. Compos. Interfaces 2012, 14, 617–630.

Kim, J.; Montero, G.; Habibi, Y.; Hinestroza, J. P.; Genzer, J.; Argyropoulos, D. S.; Rojas, O. J. Dispersion of cellulose crystallites by nonionic surfactants in a hydrophobic polymer matrix. Polym. Eng. Sci. 2009, 49, 2054–2061.

Larsson, E.; Sanchez, C. C.; Porsch, C.; Karabulut, E.; Wågberg, L.; Carlmark, A. Thermo-responsive nanofibrillated cellulose by polyelectrolyte adsorption. Eur. Polym. J. 2013, 49, 2689–2696.

Martins, N. C. T.; Freire, C. S. R.; Pinto, R. J. B.; Fernandes, S. C. M.; Pascoal, Neto C.; Silvestre, A. J. D.; Causio, J.; Baldi, G.; Sadocco, P.; Trindade, T. Electrostatic assembly of Ag nanoparticles onto nanofibrillated cellulose for antibacterial paper products. Cellulose 2012, 19, 1425–1436.

Moon, R. J.; Martini, A.; Nairn, J.; Simonsen, J.; Youngblood, J. Cellulose nanomaterials review: structure, properties and nanocomposites. Chem. Soc. Rev. 2011, 40, 3941–3994.

Habibi, Y. Key advances in the chemical modification of nanocelluloses. Chem. Soc. Rev. 2014, 43, 1519–1542.

Fotie, G.; Gazzotti, S.; Ortenzi, M. A.; Piergiovanni, L. Implementation of high gas barrier laminated films based on cellulose nanocrystals for food flexible packaging. Appl. Sci. 2020, 10, 3201.

Andresen, M.; Johansson, L. S.; Tanem, B. S.; Stenius, P. Properties and characterization of hydrophobized microfibrillated cellulose. Cellulose 2006, 13, 665–677.

Kloser, E.; Gray, D. G. Surface grafting of cellulose nanocrystals with poly(ethylene oxide) in aqueous media. Langmuir 2010, 26, 13450–13456.

Goffin, A. L.; Raquez, J. M.; Duquesne, E.; Siqueira, G.; Habibi, Y.; Dufresne, A.; Dubois, P. From interfacial ring-opening polymerization to melt processing of cellulose nanowhisker-filled polylactide-based nanocomposites. Biomacromolecules 2011, 12, 2456–2465.

Lizundia, E.; Fortunati, E.; Dominici, F.; Vilas, J. L.; Leon, L. M.; Armentano, I.; Torre, L.; Kenny, J. M. PLLA-grafted cellulose nanocrystals: Role of the CNC content and grafting on the PLA bionanocomposite film properties. Carbohydr. Polym. 2016, 142, 105–113.

de Paula, E. L.; Roig, F.; Mas, A.; Habas, J. P.; Mano, V.; Pereira, F. V.; Robin, J. J. Effect of surface-grafted cellulose nanocrystals on the thermal and mechanical properties of PLLA based nanocomposites. Eur. Polym. J. 2016, 84, 173–187.

Habibi, Y.; Aouadi, S.; Raquez, J. M.; Dubois, P. Effects of interfacial stereocomplexation in cellulose nanocrystal-filled polylactide nanocomposites. Cellulose 2013, 20, 2877–2885.

Gupta, A.; Katiyar, V. Cellulose functionalized high molecular weight stereocomplex polylactic acid biocomposite films with improved gas barrier, thermomechanical properties. ACS Sustain. Chem. Eng. 2017, 5, 6835–6844.

Wu, H.; Nagarajan, S.; Zhou, L.; Duan, Y.; Zhang, J. Synthesis and characterization of cellulose nanocrystal-graft-poly(D-lactide) and its nanocomposite with poly(L-lactide). Polymer 2016, 103, 365–375.

Wang, H.; Yu, J.; Fang, H.; Wei, H.; Wang, X.; Ding, Y. Largely improved mechanical properties of a biodegradable polyurethane elastomer via polylactide stereocomplexation. Polymer 2018, 137, 1–12.

Xie, Q.; Wang, S.; Chen, X.; Zhou, Y.; Fang, H.; Li, X.; Cheng, S.; Ding, Y. Thermal stability and crystallization behavior of cellulose nanocrystals and their poly(L-lactide) nanocomposites: effects of surface ionic group and poly(D-lactide) grafting. Cellulose 2018, 25, 6847–6862.

Fang, H.; Chen, X.; Wang, S.; Cheng, S.; Ding, Y. Enhanced mechanical and oxygen barrier performance in biodegradable polyurethanes by incorporating cellulose nanocrystals with interfacial polylactide stereocomplexation. Cellulose 2019, 26, 9751–9764.

Garlotta, D. A literature review of poly(lactic acid). J. Polym. Environ. 2001, 9, 63–84.

Chen, X.; Han, L.; Zhang, T.; Zhang, J. Influence of crystal polymorphism on crystallinity calculation of poly(L-lactic acid) by infrared spectroscopy. Vib. Spectrosc. 2014, 70, 1–5.

Ma, P.; Jiang, L.; Xu, P.; Dong, W.; Chen, M.; Lemstra, P. J. Rapid stereocomplexation between enantiomeric comb-shaped cellulose-g-poly(L-lactide) nanohybrids and poly(D-lactide) from the melt. Biomacromolecules 2015, 16, 3723–3729.

Saeidlou, S.; Huneault, M. A.; Li, H.; Park, C. B. Poly(lactic acid) crystallization. Prog. Polym. Sci. 2012, 37, 1657–1677.

Ying, Z.; Wu, D.; Wang, Z.; Xie, W.; Qiu, Y.; Wei, X. Rheological and mechanical properties of polylactide nanocomposites reinforced with the cellulose nanofibers with various surface treatments. Cellulose 2018, 25, 3955–3971.

Arias, A.; Heuzey, M.-C.; Huneault, M. A.; Ausias, G.; Bendahou, A. Enhanced dispersion of cellulose nanocrystals in melt-processed polylactide-based nanocomposites. Cellulose 2015, 22, 483–498.

Besbes, I.; Alila, S.; Boufi, S. Nanofibrillated cellulose from TEMPO-oxidized eucalyptus fibres: effect of the carboxyl content. Carbohydr. Polym. 2011, 84, 975–983.

Muiruri, J. K.; Liu, S.; Teo, W. S.; Kong, J.; He, C. Highly biodegradable and tough polylactic acid-cellulose nanocrystal composite. ACS Sustain. Chem. Eng. 2017, 5, 3929–3937.

Liu, H.; Bai, D.; Bai, H.; Zhang, Q.; Fu, Q. Constructing stereocomplex structures at the interface for remarkably accelerating matrix crystallization and enhancing the mechanical properties of poly(L-lactide)/multi-walled carbon nanotube nanocomposites. J. Mater. Chem. A 2010, 3, 13835–13847.

Mano, J. O. F.; Wang, Y.; Viana, J. I. C.; Denchev, Z.; Oliveira, M. J. Cold crystallization of PLLA studied by simultaneous SAXS and WAXS. Macromol. Mater. Eng. 2004, 289, 910–915.

Xu, C.; Lv, Q.; Wu, D.; Wang, Z. Polylactide/cellulose nanocrystal composites: a comparative study on cold and melt crystallization. Cellulose 2017, 24, 2163–2175.

Liang, Y.; Xu, J.; Li, Y.; Zhong, G.; Wang, R.; Li, Z. Promoting interfacial transcrystallization in polylactide/ramie fiber composites by utilizing stereocomplex crystals. ACS Sustain. Chem. Eng. 2017, 5, 7128–7136.

Zhang, Y.; Xu, Z.; Wang, Z.; Ding, Y.; Wang, Z. Strong enhancements of nucleation and spherulitic growth rates through amplified interfacial effects for immiscible linear polymer/comb-like copolymer double-layer films. RSC Adv. 2014, 4, 20582–20591.

Zhang, Y..; Wang, Z. Increased spherulitic growth rates of semicrystalline polymer due to enhanced limited local chain segmental mobility at the interface of double-layer thin films. Chinese J. Polym. Sci. 2013, 31, 1276–1283.

Housmans, J. W.; Steenbakkers, R. J. A.; Roozemond, P. C.; Peters, G. W. M.; Meijer, H. E. H. Saturation of pointlike nuclei and the transition to oriented structures in flow-induced crystallization of isotactic polypropylene. Macromolecules 2009, 42, 5728–5740.

Fang, H.; Zhang, Y.; Bai, J.; Wang, Z. Shear-induced nucleation and morphological evolution for bimodal long chain branched polylactide. Macromolecules 2013, 46, 6555–6565.

Acknowledgments

This work was financially supported by the National Natural Science Foundation of China (Nos. 51503055 and 51673056) and the Fundamental Research Funds for the Central Universities (No. PA2020GDKC0009).

Author information

Authors and Affiliations

Corresponding authors

Additional information

Notes

The authors declare no competing financial interest.

Electronic Supplementary Information for

10118_2021_2635_MOESM1_ESM.pdf

Influence of Interfacial Enantiomeric Grafting on Melt Rheology and Crystallization of Polylactide/Cellulose Nanocrystals Composites

Rights and permissions

About this article

Cite this article

Fang, HG., Yang, KJ., Xie, QZ. et al. Influence of Interfacial Enantiomeric Grafting on Melt Rheology and Crystallization of Polylactide/Cellulose Nanocrystals Composites. Chin J Polym Sci 40, 93–106 (2022). https://doi.org/10.1007/s10118-021-2635-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10118-021-2635-7