Abstract

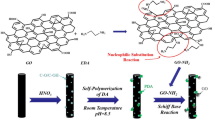

In order to enhance the interfacial adhesion of carbon fiber (CF) and polymer matrix, a multiscale gradient modulus intermediate layer with rigid-flexible (GO-PA) hierarchical structure was designed and fabricated between CFs and matrix by a facile and businesslike strategy. The polarity, roughness and wettability of CFs surface as well as the thickness of intermediate layer in composite have been significantly increased after rigid-flexible hierarchical structure was constructed. The IFSS, ILSS, compression and impact toughness manifested that the hierarchical structure could bring about a fantastic improvement (76.8%, 46.4%, 40.7% and 37.8%) for the interfacial and mechanical properties than other previous reports. Consequently, the establishment of CF surface with gradient modulus rigid-flexible hierarchical structure via regulation of nanoparticles and polymer array would open a new, viable and promising route to obtaining high-performance composites.

Similar content being viewed by others

References

Gu, S. L.; Liu, H. H.; Cao, H.; Mercier, C.; Li, Y. J. Investigations on the interactions between Li-TFSI and glass fibers in the ternary PP/GF/Li-TFSI composites. Chinese J. Polym. Sci. 2018, 36, 113–118.

Zheng, N.; Huang, Y. D.; Sun, W.; Du, X.; Liu, H. In-situ pull-off of ZnO nanowire from carbon fiber and improvement of interlaminar toughness of hierarchical ZnO nanowire/carbon fiber hydrid composite laminates. Carbon 2016, 110, 69–78.

Zhao, Q.; Liu, R.; Jiao, Q.; Zhu, T.; Wang, J. Simultaneous improvement of interfacial strength and toughness between carbon fiber and epoxy by introducing amino functionalized ZrO2 on fiber surface. Mater. Design 2018, 149, 15–24.

Huang, S.; Wu, G.; Chen, C.; Yu, Y. Electrophoretic deposition and thermal annealing of a graphene oxide thin film on carbon fiber surfaces. Carbon 2013, 52, 613–616.

Liu, L.; Jia, C.; He, J.; Zhao, F.; Fan, D.; Xing, L.; Wang, M.; Wang, F.; Jiang, Z.; Huang, Y. Interfacial characterization, control and modification of carbon fiber reinforced polymer composites. Compos. Sci. Technol. 2015, 121, 56–72.

Shi, L.; Song, G.; Li, P.; Li, X.; Huang, Y.; Ma, L. Enhancing interfacial performance of epoxy resin composites via in-situ nucleophilic addition polymerization modification of carbon fibers with hyperbranched polyimidazole. Compos. Sci. Technol. 2021, 201, 108522.

Zheng, Y. W.; Wang, X. Y.; Wu, G. S. Chemical modification of carbon fiber with diethylenetriaminepentaacetic acid/halloysite nanotube as a multifunctional interfacial reinforcement for silicone resin composites. Polym. Adv. Technol. 2020, 31, 527–535.

Ma, L.; Zhu, Y.; Wang, M.; Yang, X.; Song, G.; Huang, Y. Enhancing interfacial strength of epoxy resin composites via evolving hyperbranched amino-terminated POSS on carbon fiber surface. Compos. Sci. Technol. 2019, 170, 148–156.

Yang, X. L.; Li, K.; Xu, M. Z.; Liu, X. B. Designing a phthalonitrile/benzoxazine blend for the advanced GFRP composite material. Chinese J. Polym. Sci. 2018, 36, 106–112.

Borooj, M. B.; Shoushtari, A. M.; Haji, A.; Sabet, E. N. Optimization of plasma treatment variables for the improvement of carbon fibres/epoxy composite performance by response surface methodology. Compos. Sci. Technol. 2016, 128, 215–221.

Peng, Q.; Li, Y.; He, X.; Lv, H.; Hu, P.; Shang, Y.; Wang, C.; Wang, R.; Sritharan, T.; Du, S. Interfacial enhancement of carbon fiber composites by poly(amido amine) functionalization. Compos. Sci. Technol. 2013, 74, 37–42.

Zheng, W.; Chen, L.; Wang, X. Y.; Wu, G. S. Modification of renewable cardanol onto carbon fiber for the improved interfacial properties of advanced polymer composites. Polymers 2020, 12, 45.

Zhang, X.; Fan, X.; Yan, C.; Li, H.; Zhu, Y.; Li, X.; Yu, L. Interfacial microstructure and properties of carbon fiber composites modified with graphene oxide. ACS Appl. Mater. Interfaces 2012, 4, 1543–1552.

Qiu, B.; Sun, T.; Li, M.; Chen, Y.; Zhou, S.; Liang, M.; Zou, H. High micromechanical interlocking graphene oxide/carboxymethyl cellulose composite architectures for enhancing the interface adhesion between carbon fiber and epoxy. Compos. A: Appl. Sci. Manuf. 2020, 139, 106092.

Feng, P.; Ma, L.; Wu, G.; Li, X.; Zhao, M.; Shi, L.; Wang M.; Wang, X.; Song, G. Establishment of multistage gradient modulus intermediate layer between fiber and matrix via designing double “rigid-flexible” structure to improve interfacial and mechanical properties of carbon fiber/resin composites. Compos. Sci. Technol. 2020, 200, 108336.

Li, Y.; Jiang, B.; Huang, Y. Constructing nanosheet-like MOF on the carbon fiber surfaces for improving the interfacial properties of carbo fiber/epoxy composites. Appl. Surf. Sci. 2020, 514, 145870.

Feng, P.; Song, G.; Li, X.; Xu, H.; Xu, L.; Zhu, X.; Huang, Y.; Ma, L. Effects of different “rigid-flexible” structures of carbon fibers surface on the interfacial microstructure and mechanical properties of carbon fiber/epoxy resin composites. J. Colloid. Interf. Sci. 2021, 583, 13–23.

Li, Y.; Peng, Q.; He, X.; Hu, P.; Lv, H. Synthesis and characterization of a new hierarchical reinforcement by chemically grafting graphene oxide onto carbon fibers. J. Mater. Chem. 2012, 22, 18748–18752.

Ma, Y.; Yan, C.; Xu, H.; Liu, D.; Liu, J. Enhanced interfacial properties of carbon fiber reinforced polyamide 6 composites by grafting graphene oxide onto fiber surface. Appl. Surf. Sci. 2018, 452, 286–298.

Wu, G.; Chen, L.; Liu, L.; Huang, Y. Multiscale carbon fiber-graphene oxide reinforcements for silicone resin composites with simultaneously enhanced interfacial strength and antihydrothermal aging behaviors. Polym. Compos. 2018, 39, 3509–3518.

Wen, Z.; Qian, X.; Zhang, Y.; Wang, X.; Wang, W.; Song, S. Electrochemical polymerization of carbon fibers and its effect on the interfacial properties of carbon reinforced epoxy resin composites. Compos. A: Appl. Sci. Manuf. 2019, 119, 21–29.

Jia, J.; Kan, C. M.; Lin, X.; Shen, X.; Kim, J. K. Effects of processing and material parameters on synthesis of monolayer ultralarge graphene oxide sheets. Carbon 2014, 77, 244–254.

Chen, H.; Cai, Q. Y.; Wu, J.; Xia, X. H.; Liu, H. B.; Luo, Z. J. Interfacial enhancement of carbon fiber/nylon 12 composites by grafting nylon 6 to the surface of carbon fiber. Appl. Surf. Sci. 2018, 441, 538–545.

Reis, V. L.; Opelt, C. V.; Cândido, G. M.; Rezende, M. C.; Donadon, M. V. Effect of fiber orientation on the compressive response of plain weave carbon fiber/epoxy composites submitted to high strain rates. Compos. Struct. 2018, 203, 952–959.

Ma, L.; Meng, L.; Wu, G.; Wang, Y.; Zhao, M.; Zhang, C.; Huang, Y. Effects of bonding types of carbon fibers with branched polyethyleneimine on the interfacial microstructure and mechanical properties of carbon fiber/epoxy resin composites. Compos. Sci. Technol. 2015, 117, 289–297.

Wang, C.; Chen, L.; Li, J.; Sun, S.; Ma, L.; Wu, G.; Zhao, F.; Jiang, B.; Huang, Y. Enhancing the interfacial strength of carbon fiber reinforced epoxy composites by green grafting of poly(oxypropylene) diamines. Compos. A: Appl. Sci. Manuf. 2017, 99, 58–64.

Zhao, Z.; Teng, K.; Li, N.; Li, X.; Xu, Z.; Chen, L.; Niu, J.; Fu, H.; Zhao, L.; Liu, Y. Mechanical, thermal and interfacial performances of carbon fiber reinforced composites flavored by carbon nanotube in matrix/interface. Compos. Struct. 2017, 159, 761–772.

Yuan, X.; Zhu, B.; Cai, X.; Qiao, K.; Zhao, S.; Zhang, M.; Yu, J. Microconfiguration controlled interfacial adhesion by grafting graphene oxide onto carbon fibers. Compos. A: Appl. Sci. Manuf. 2018, 111, 83–93.

Ma, L.; Zhu, Y.; Feng, P.; Song, G.; Huang, Y.; Liu, H.; Zhang, J.; Fan, J.; Hou, H.; Guo, Z. Reinforcing carbon fiber epoxy composites with triazine derivatives functionalized graphene oxide modified sizing agent. Compos. Part B Eng. 2019, 176, 107078.

Xu, P.; Yu, Y.; Liu, D.; He, M.; Li, G.; Yang, X. Enhanced interfacial and mechanical properties of high-modulus carbon fiber composites: establishing modulus intermediate layer between fiber and matrix based on tailored-modulus epoxy. Compos. Sci. Technol. 2018, 163, 26–33.

Acknowledgments

This work was financially supported by the National Natural Science Foundation of China (Nos. 51803102 and 51903129), Natural Science Foundation of Shandong Province (Nos. 201807070028 and 201808220020) and the Source Innovation Project of Qingdao (No. 19-6-2-75-cg), Industry and Education Cooperation Program of The Ministry of Education (Nos. 201802201002, 201901078008 and 201802230009) and Opening Project of Shanxi Province Key Laboratory of Functional Nanocomposites, North University of China (No. NFCM202001).

Author information

Authors and Affiliations

Corresponding authors

Rights and permissions

About this article

Cite this article

Feng, PF., Song, GJ., Zhang, WJ. et al. Interfacial Improvement of Carbon Fiber/Epoxy Composites by Incorporating Superior and Versatile Multiscale Gradient Modulus Intermediate Layer with Rigid-flexible Hierarchical Structure. Chin J Polym Sci 39, 896–905 (2021). https://doi.org/10.1007/s10118-021-2549-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10118-021-2549-4