Abstract

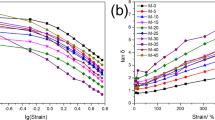

The aging behaviors and mechanism of fluoroelastomer (FKM) under lubricating oil (FKM-O) and air (FKM-A, as a comparison) at elevated temperatures were studied from both physical and chemical viewpoints. The obvious changes of mechanical and swelling performances indicate that the coupling effect of lubricating oil and temperature causes more serious deterioration of FKM-O compared to that of FKM-A. Meanwhile, much stronger temperature dependence of both bulk properties and micro-structures for FKM-O is found. Three-stage physical diffusion process is defined in FKM-O due to the competition between oil diffusion and elastic retraction of network. FTIR results reveal that the dehydrofluorination reaction causes the fracture of C-F bonds and produces a large number of C-C bonds in the backbone. The coupling effect of oil medium and high temperature could accelerate the scission of C-C bonds and generate a series of fragments with different molecular sizes. The TGA results, crosslinking density Ve, and glass transition temperature Tg derived from different measurements coherently demonstrate the network destruction in the initial stage and the simultaneous reconstruction occurring at the final stage. The newly formed local network induced by reconstruction cannot compensate the break of the original rubber network and thus only provides lower tensile strength and thermal stability.

Similar content being viewed by others

References

Ameduri, B.; Boutevin, B.; Kostov, G. Fluoroelastomers: synthesis, properties and applications. Prog. Polym. Sci.2001, 26, 105–187.

Li, D. H.; Liao, M. Y. Dehydrofluorination mechanism, structure and thermal stability of pure fluoroelastomer (poly(VDF-ter-HFP-ter-TFE) terpolymer) in alkaline environment. J. Fluorine. Chem. 2017, 201, 55–67.

Wang, Y.; Bai, Y. P. The functionalization of fluoroelastomers: approaches, properties and applications. RSC Adv. 2016, 6, 53730–53748.

Moore, A. L. Fluoroelastomers handbook. Norwish, William Andrew Publishing, 2006.

Mofidi, M.; Kassfeldt, E.; Prakash, B. Tribological behaviour of an elastomer aged in different oils. Tri. Int.2008, 41, 860–866.

Lou, W. T.; Zhang, W. F.; Jin, T. Z.; Liu, X. R.; Dai, W. Synergistic effects of multiple environmental factors on degradation of hydrogenated nitrile rubber seals. Polymers2018, 10, 897.

Xia, L. C.; Wang, M.; Wu, H.; Guo, S. Y. Effects of cure system and filler on chemical aging behavior of fluoroelastomer in simulated proton exchange membrane fuel cell environment. Int. J. Hydrogen. Energy2016, 41, 2887–2895.

Maiti, M.; Mitra, S.; Bhowmick, A. K. Effect of nanoclays on high and low temperature degradation of fluoroelastomers. Polym. Degrad. Stab.2008, 93, 188–200.

Choi, S. S.; Jose, J.; Lyu, M. Y.; Huh, Y. I.; Cho, B. H.; Nah, C. Influence of filler and cure systems on thermal aging resistance of natural rubber vulcanizates under strained condition. J. Appl. Polym. Sci.2010, 118, 3074–3081.

Mitra, S.; Ghanbari-Siahkali, A.; Kingshott, P.; Almdal, K.; Rehmeier, H. K.; Christensen, A. G. Chemical degradation of fluoroelastomer in an alkaline environment. Polym. Degrad. Stab.2003, 83, 195–206.

Mitra, S.; Ghanbari-Siahkali, A.; Kingshott, P.; Hvilsted, S.; Almdal, K. Chemical degradation of an uncrosslinked pure fluororubber in an alkaline environment. J. Polym. Sci., Part A: Polym. Chem.2004, 42, 6216–6229.

Akhlaghi, S.; Pourrahimi, A. M.; Sjostedt, C.; Bellander, M.; Hedenqvist, M. S.; Gedde, U. W. Degradation of fluoroelastomers in rapeseed biodiesel at different oxygen concentrations. Polym. Degrad. Stab.2017, 136, 10–19.

Akhlaghi, S.; Gedde, U. W.; Hedenqvist, M. S.; Conde Brana, M. T.; Bellander, M. Deterioration of automotive rubbers in liquid biofuels: a review. Renew. Sustain. Energy Rev.2015, 43, 1238–1248.

Sugama, T. Surface analyses of fluoroelastomer bearings exposed to geothermal environments. Mater. Lett.2001, 50, 66–72.

Lin, C. W.; Chien, C. H.; Tan, J. Z.; Chao, Y. J.; van Zee, J. W. Chemical degradation of five elastomeric seal materials in a simulated and an accelerated PEM fuel cell environment. J. Power Sources2011, 196, 1955–1966.

Sugama, T.; Pyatina, T.; Redline, E.; McElhanon, J.; Blankenship, D. Degradation of different elastomeric polymers in simulated geothermal environments at 300 °C. Polym. Degrad. Stab. 2015, 120, 328–339.

Heidarian, J. Aging of carbon nanotube-filled fluoroelastomer in oil-based drilling fluid. Polimery2018, 63, 191–212.

Liu, X.; Zhao, J. H.; Yang, R.; Iervolino, R.; Barbera, S. Effect of lubricating oil on thermal aging of nitrile rubber. Polym. Degrad. Stab.2018, 151, 136–143.

Liu, X.; Zhao, J. H.; Liu, Y.; Yang, R. Volatile components changes during thermal aging of nitrile rubber by flash evaporation of Py-GC/MS. J. Anal. Appl. Pyrolysis.2015, 113, 193–201.

Yu, Z. H.; Herndon, S. C.; Ziemba, L. D.; Timko, M. T.; Liscinsky, D. S.; Anderson, B. E.; Miake-Lye, R. C. Identification of lubrication oil in the particulate matter emissions from engine exhaust of inservice commercial aircraft. Environ. Sci. Technol.2012, 46, 9630–9637.

Schmiegel, W. W.; Logothetis, A. L. Curing of vinylidene fluoride based fluoroelastomers. ACS Symp. Ser.1984, 260, 159–182.

Rooj, S.; Das, A.; Heinrich, G. Tube-like natural halloysite/fluoroe-lastomer nanocomposites with simultaneous enhanced mechanical, dynamic mechanical and thermal properties. Eur. Polym. J.2011, 47, 1746–1755.

Haroonabadi, L.; Dashti, A.; Najipour, M. Investigation of the effect of thermal aging on rapid gas decompression (RGD) resistance of nitrile rubber. Polym. Test.2018, 67, 37–45.

Niu, Y. H.; Liang, W. B.; Zhang, Y. L.; Chen, X. L.; Lai, S. Y.; Li, G. X.; Wang, D. J. Crosslinking kinetics of polyethylene with small amount of peroxide and its influence on the subsequent crystallization behaviors. Chinese J. Polym. Sci.2016, 34, 1117–1128.

Banik, I.; Bhowmick, A. K.; Raghavan, S. V.; Majali, A. B.; Tikku, V. K. Thermal degradation studies of electron beam cured terpolymeric fluorocarbon rubber. Polym. Degrad. Stab.1999, 63, 413–421.

Kader, M. A.; Bhowmick, A. K. Thermal ageing, degradation and swelling of acrylate rubber, fluororubber and their blends containing polyfunctional acrylates. Polym. Degrad. Stab. 2003, 79, 283–295.

Luo, Y. F.; Zou, J.; Li, J.; Zou, H. W.; Liang, M. Effect of crosslinking agent on properties and morphology of water-blown semirigid polyurethane foam. J. Appl. Polym. Sci.2018, 135, 46753.

Kadlcak, J.; Kuritka, I.; Tunnicliffe, L. B.; Cermak, R. Rapid Payne effect test—a novel method for study of strain-softening behavior of rubbers filled with various carbon blacks. J. Appl. Polym. Sci.2015, 132, 41976.

Barjasteh, E.; Kar, N.; Nutt, S. R. Effect of filler on thermal aging of composites for next-generation power lines. Compos. Part. A-Appl. S.2011, 42, 1873–1882.

Bandzierz, K.; Reuvekamp, L.; Dryzek, J.; Dierkes, W.; Blume, A.; Bielinski, D. Influence of network structure on glass transition temperature of elastomers. Materials2016, 9, 607.

Acknowledgments

This work was financially supported by the Joint Foundation from Ministry of Education and Advanced Research of Equipment (No. 6141A02022201), the National Natural Science Foundation of China (Nos. U19A2096 and 51721091), and Department of Science and Technology of Sichuan Province (No. 2019YFH0027).

Author information

Authors and Affiliations

Corresponding authors

Electronic Supplementary Information

Rights and permissions

About this article

Cite this article

Wang, QL., Pei, JK., Li, G. et al. Accelerated Aging Behaviors and Mechanism of Fluoroelastomer in Lubricating Oil Medium. Chin J Polym Sci 38, 853–866 (2020). https://doi.org/10.1007/s10118-020-2410-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10118-020-2410-1