Abstract

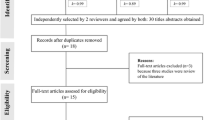

There are numerous functions for laser in modern implant dentistry including surface treatment, surface coating, and implant manufacturing. As laser application may potentially improve osseointegration of dental implants, we systematically reviewed the literature for in vitro biological responses to laser-modified or processed titanium dental implants. The literature was searched in PubMed, ISI Web, and Scopus, using keywords “titanium dental implants,” “laser,” “biocompatibility,” and their synonyms. After screening the 136 references obtained, 28 articles met the inclusion criteria. We found that Nd:YAG laser was the most commonly used lasers in the treatment or processing of titanium dental implants. Most of the experiments used cell attachment and cell proliferation to investigate bioresponses of the implants. The most commonly used cells in these assays were osteoblast-like cells. Only one study was conducted in stem cells. These in vitro studies reported higher biocompatibility in laser-modified titanium implants. It seems that laser radiation plays a vital role in cell response to dental implants; however, it is necessary to accomplish more studies using different laser types and parameters on various cells to offer a more conclusive result.

Similar content being viewed by others

References

Sakaguchi RL, Powers JM (2013) Craig’s restorative dental materials, 13th edn. Mosby: Elsevier, USA

Anusavice KJ, Shen C, Rawls HR (2012) Phillip’s science of dental materials, 12th edn. Saunders, St. Louis

Kasemo B (1983) Biocompatibility of titanium implants: surface science aspects. J Prosthet Dent 49(6):832–837

Saini M, Singh Y, Arora P, Arora V, Jain K (2015) Implant biomaterials: a comprehensive review. World J Clin Cases 3(1):52–57

Branemark P, Adell R, Breine U, Hansson B, Lindström J, Ohlsson A (1969) Intra-osseous anchorage of dental prostheses. I. Experimental studies. Scand J Plast Reconstr Surg 3(2):81–100

Anil S, Alghamdi H, Jansen J, Anand P (2011) Dental implant surface enhancement and osseointegration. In: Turkyilmaz I (ed) Implant dentistry—a rapidly evolving practice. InTech, Croatia, pp 83–108

Wall I, Donos N, Carlqvist K, Jones F, Brett P (2009) Modified titanium surfaces promote accelerated osteogenic differentiation of mesenchymal stromal cells in vitro. Bone 45(1):17–26

Raines AL, Olivares-Navarrete R, Wieland M, Cochran DL, Schwartz Z, Boyan BD (2010) Regulation of angiogenesis during osseo integration by titanium surface microstructure and energy. Biomaterials 31(18):4909–4917

Buser D, Janner SF, Wittneben JG, Bragger U, Ramseier CA, Salvi GE (2012) 10-year survival and success rates of 511 titanium implants with a sandblasted and acid-etched surface: a retrospective study in 303 partially edentulous patients. Clin Implant Dent Relat Res 14(6):839–851

Dohan Ehrenfest DM, Coelho PG, Kang BS, Sul YT, Albrektsson T (2010) Classification of osseointegrated implant surfaces: materials, chemistry and topography. Trends Biotechnol 28(4):198–206

Novaes AB Jr, de Souza SL, de Barros RR, Pereira KK, Iezzi G, Piattelli A (2010) Influence of implant surfaces on osseointegration. Braz Dent J 21(6):471–481

Ulerich JP, Ionescu LC, Chen J, Soboyejo WO, Arnold CB, editors. Modifications of Ti-6Al-4V surfaces by direct-write laser machining of linear grooves. Lasers and Applications in Science and Engineering; 2007: International Society for Optics and Photonics.

Deppe H, Horch HH (2007) Laser applications in oral surgery and implant dentistry. Lasers Med Sci 22:217–221

Brunette DM (1988) The effects of implant surface topography on the behavior of cells. Int J Oral Maxillofac Implants 3(4):231–246

Mariscal-Munoz E, Costa CA, Tavares HS et al (2016) Osteoblast differentiation is enhanced by a nano-to-micro hybrid titanium surface created by Yb:YAG laser irradiation. Clin Oral Investig 20(3):503–511

Hara T, Matsuoka K, Matsuzaka K, Yoshinari M, Inoue T (2012) Effect of surface roughness of titanium dental implant placed under periosteum on gene expression of bone morphogenic markers in rat. Bull Tokyo Dent Coll 53(2):45–50

Velasco-Ortega E, Jos A, Camean AM, Pato-Mourelo J, Segura-Egea JJ (2010) In vitro evaluation of cytotoxicity and genotoxicity of a commercial titanium alloy for dental implantology. Mutat Res 702(1):17–23

Le Guehennec L, Lopez-Heredia MA, Enkel B, Weiss P, Amouriq Y, Layrolle P (2008) Osteoblastic cell behaviour on different titanium implant surfaces. Acta Biomater 4(3):535–543

Parthasarathy J, Starly B, Raman S, Christensen A (2010) Mechanical evaluation of porous titanium (Ti6Al4V) structures with electron beam melting (EBM). J Mech Behav Biomed Mater 3(3):249–259

Sumner DR, Galante JO (1992) Determinants of stress shielding: design versus materials versus interface. Clin Orthop Relat Res 274:202–212

Traini T, Mangano C, Sammons RL, Mangano F, Macchi A, Piattelli A (2008) Direct laser metal sintering as a new approach to fabrication of an isoelastic functionally graded material for manufacture of porous titanium dental implants. Dent Mater 24(11):1525–1533

Mangano C, De Rosa A, Desiderio V et al (2010) The osteoblastic differentiation of dental pulp stem cells and bone formation on different titanium surface textures. Biomaterials 31(13):3543–3551

Groessner-Schreiber B, Neubert A, Muller WD, Hopp M, Griepentrog M, Lange KP. Fibroblast growth on surface-modified dental implants: an in vitro study. J Biomed Mater Res A 15:64(4):591–9.

Schwarz F, Rothamel D, Sculean A, Georg T, Scherbaum W, Becker J (2003) Effects of an Er:YAG laser and the vector ultrasonic system on the biocompatibility of titanium implants in cultures of human osteoblast-like cells. Clin Oral Implants Res 14:784–792

Hao L, Lawrence J, Chian KS (2005) Osteoblast cell adhesion on a laser modified zirconia based bioceramic. J Mater Sci Mater Med 16(8):719–726

Lawrence J, Hao L, Chew HR (2006) On the correlation between Nd:YAG laser-induced wettability characteristics modification and osteoblast cell bioactivity on a titanium alloy. Surf Coat Tech 200(18–19):5581–5589

Ayobian-Markazi N, Karimi M, Safar-Hajhosseini A (2013) Effects of Er: YAG laser irradiation on wettability, surface roughness, and biocompatibility of SLA titanium surfaces: an in vitro study. Lasers Med Sci 30(2):561–566

Heinrich A, Dengler K, Koerner T, Haczek C, Deppe H, Stritzker B (2008) Laser-modified titanium implants for improved cell adhesion. Lasers Med Sci 23(1):55–58

Erdogan M, Oktem B, Kalaycioglu H et al (2011) Texturing of titanium (Ti6Al4V) medical implant surfaces with MHz-repetition-rate femtosecond and picosecond Yb-doped fiber lasers. Opt Express 19(11):10986–10996

Paz MD, Alava JI, Goikoetxea L et al (2011) Biological response of laser macrostructured and oxidized titanium alloy: an in vitro and in vivo study. J Appl Biomater Biomech 9(3):214–222

Ayobian-Markazi N, Fourootan T, Zahmatkesh A (2012) An in vitro evaluation of the responses of human osteoblast-like SaOs-2 cells to SLA titanium surfaces irradiated by erbium:yttrium-aluminum-garnet (Er:YAG) lasers. Lasers Med Sci 29(1):47–53

Györgyey Á, Ungvári K, Kecskeméti G et al (2013) Attachment and proliferation of human osteoblast-like cells (MG-63) on laser-ablated titanium implant material. Mater Sci Eng C Mater Biol Appl 33(7):4251–4259

Chikarakara E, Fitzpatrick P, Moore E et al (2015) In vitro fibroblast and pre-osteoblastic cellular responses on laser surface modified Ti-6Al-4V. Biomed Mater 10(1):015007

Vignesh, Nayar S, Bhuminathan, Mahadevan, Santhosh S (2015) Comparative evaluation of the three different surface treatments—conventional, laser and Nano technology methods in enhancing the surface characteristics of commercially pure titanium discs and their effects on cell adhesion: an in vitro study. J Pharm Bioallied Sci 7(Suppl 1):587–591

Mukherjee S, Dhara S, Saha P (2015) Enhancing the biocompatibility of Ti6Al4V implants by laser surface microtexturing: an in vitro study. Int J Adv Manufac Tech 76(1):5–15

Hsiao W-T, Chang H-C, Nanci A, Durand R (2016) Surface microtexturing of Ti–6Al–4V using an ultraviolet laser system. Mater Des 90:891–895

Lusquinos F, De Carlos A, Pou J et al (2003) Calcium phosphate coatings obtained by Nd:YAG laser cladding: physicochemical and biologic properties. J Biomed Mater Res A 64(4):630–637

Seydlova M, Teuberova Z, Dostalova T et al (2006) Biological properties of titanium implants covered with hydroxyapatite and zirconia layers by pulsed laser: in vitro study. J Appl Phys 99(1):014905

Teuberova Z, Seydlova M, Dostalova T et al (2007) Biological and physical properties of pulsed-laser-deposited zirconia/hydroxyapatite on titanium: in vitro study. Laser Phys 17(1):45–49

Bose S, Roy M, Das K, Bandyopadhyay A (2009) Surface modification of titanium for load-bearing applications. J Mater Sci Mater Med 20(Suppl 1):S19–S24

Gao Y, Hu J, Guan TH, Wu J, Zhang CB, Gao B (2014) Physical properties and cellular responses to calcium phosphate coating produced by laser rapid forming on titanium. Lasers Med Sci 29(1):9–17

Oyane A, Matsuoka N, Koga K et al (2015) Laser-assisted biomimetic process for surface functionalization of titanium metal. Colloids Interface Sci Comm 4:5–9

Hollander DA, von Walter M, Wirtz T et al (2006) Structural, mechanical and in vitro characterization of individually structured Ti–6Al–4V produced by direct laser forming. Biomaterials 27(7):955–963

Xue W, Krishna BV, Bandyopadhyay A, Bose S (2007) Processing and biocompatibility evaluation of laser processed porous titanium. Acta Biomater 3(6):1007–1018

Mangano C, Raspanti M, Traini T, Piattelli A, Sammons R (2009) Stereo imaging and cytocompatibility of a model dental implant surface formed by direct laser fabrication. J Biomed Mater Res A 88(3):823–831

Shishkovskii IV, Morozov YG, Fokeev SV, Volova LT (2012) Laser synthesis and comparative testing of a three dimensional porous matrix of titanium and titanium nickelide as a repository for stem cells. Powder Metall Met Ceram 50(9):606–618

Cheng A, Humayun A, Cohen DJ, Boyan BD, Schwartz Z (2014) Additively manufactured 3D porous Ti-6Al-4V constructs mimic trabecular bone structure and regulate osteoblast proliferation, differentiation and local factor production in a porosity and surface roughness dependent manner. Biofabrication 6(4):045007

Bidan CM, Kommareddy KP, Rumpler M, Kollmannsberger P, Fratzl P, Dunlop JW (2013) Geometry as a factor for tissue growth: towards shape optimization of tissue engineering scaffolds. Adv Healthc Mater 2(1):186–194

Gaković B, Desai T, Trtica M, et al. Laser ablation of multi-layered targets with short laser pulses. 3rd international conference on the frontiers of Plasma Physics and Technology 2007.

Gaggl A, Schultes G, Muller WD, Karcher H (2000) Scanning electron microscopical analysis of laser-treated titanium implant surfaces—a comparative study. Biomaterials 21(10):1067–1073

Pachauri P, Bathala LR, Sangur R (2014) Techniques for dental implant nanosurface modifications. J Adv Prosthodont 6(6):498–504

Sjostrom T, Brydone AS, Meek RM, Dalby MJ, Su B, McNamara LE (2013) Titanium nanofeaturing for enhanced bioactivity of implanted orthopedic and dental devices. Nanomedicine (Lond) 8(1):89–104

Chen H, Sago A, West S, Farina J, Eckert J, Broadley M (2011) Biocompatibility of metal injection molded versus wrought ASTM F562 (MP35N) and ASTM F1537 (CCM) cobalt alloys. Biomed Mater Eng 21(1):1–7

Kumar G, Tison CK, Chatterjee K et al (2011) The determination of stem cell fate by 3D scaffold structures through the control of cell shape. Biomaterials 32(35):9188–9196

Poulon-Quintin A, Watanabe I, Watanabe E, Bertrand C (2012) Microstructure and mechanical properties of surface treated cast titanium with Nd:YAG laser. Dental Mater 28(9):945–951

Ciganovic J, Stasic J, Gakovic B et al (2012) Surface modification of the titanium implant using TEA CO2 laser pulses in controllable gas atmospheres—comparative study. Appl Surf Sci 258(7):2741–2748

Trtica M, Gakovic B, Batani D, Desai T, Panjan P, Radak B (2006) Surface modifications of a titanium implant by a picosecond Nd:YAG laser operating at 1064 and 532 nm. Appl Surf Sci 253(5):2551–2556

Ricci J, Charvet J, Frenkel S, et al. Bone response to laser microtextured surfaces. In: JE D, editor. Bone engineering. Toronto: Em2 Inc 2000. p. 1–11.

Vorobyev AY, Guo C, editors. Femtosecond laser surface structuring of biocompatible metals. Commercial and Biomedical Applications of Ultrafast Lasers IX; 2009: Proc. of SPIE.

Karacs A, Joob Fancsaly A, Divinyi T, Pető G, Kovách G (2003) Morphological and animal study of titanium dental implant surface induced by blasting and high intensity pulsed Nd-glass laser. Mater Sci Eng C Mater Biol Appl 23(3):431–435

Braga FJC, Marques RFC, Filho EA, Guastaldi AC (2007) Surface modification of Ti dental implants by Nd:YVO4 laser irradiation. Appl Surf Sci 253(23):9203–9208

Tabatabaei F, Torshabi M, Mojahedi Nasab M, Khosraviani K, Khojasteh A (2015) Effect of low-level diode laser on proliferation and osteogenic differentiation of dental pulp stem cells. Laser Phys 25(9):095602

Laoui T, Santos E, Osakada K et al (2006) Properties of titanium dental implant models made by laser processing. J Mech Eng Sci 220(c):857–863

Ready JF (1997) Industrial applications of lasers. Academic Press, San Diego

Fuchs E, Mandel K, Bouazza S, Rosin A, Weiss E, Willert-Porada M. Surface modification of porous titanium composites obtained by different processing methods. 17th Plansee Seminars 2009. p. 1–7.

Guo Z, Zhou L, Rong M, Zhu A, Geng H (2010) Bone response to a pure titanium implant surface modified by laser etching and microarc oxidation. Int J Oral Maxillofac Implants 25(1):130–136

Tavangar A, Tan B, Venkatakrishnan K (2011) Synthesis of bio-functionalized three-dimensional titania nanofibrous structures using femtosecond laser ablation. Acta Biomater 7(6):2726–2732

Bruschi M, Steinmüller-Nethl D, Goriwoda W, Rasse M (2015) Composition and modifications of dental implant surfaces. J Oral Implants 2015:14

Rajesh P, Muraleedharan CV, Komath M, Varma H (2011) Laser surface modification of titanium substrate for pulsed laser deposition of highly adherent hydroxyapatite. J Mater Sci Mater Med 22(7):1671–1679

Filho EA, Fraga AF, Bini RA, Guastaldi AC (2011) Bioactive coating on titanium implants modified by Nd:YVO4 laser. Appl Surf Sci 257(10):4575–4580

Symietz C, Lehmann E, Gildenhaar R, Koter R, Berger G, Krüger J (2011) Fixation of bioactive calcium alkali phosphate on Ti6Al4V implant material with femtosecond laser pulses. Appl Surf Sci 257(12):5208–5212

Murr LE, Quinones SA, Gaytan SM et al (2009) Microstructure and mechanical behavior of Ti-6Al-4V produced by rapid-layer manufacturing, for biomedical applications. J Mech Behav Biomed Mater 2(1):20–32

Chen J, Zhang Z, Chen X, Zhang C, Zhang G, Xu Z (2014) Design and manufacture of customized dental implants by using reverse engineering and selective laser melting technology. J Prosthet Dent 112(5):1088–95.e1

Liu J, Han G, Pan S, Ge Y, Feng H, Shen Z (2015) Biomineralization stimulated peri-titanium implants prepared by selective laser melting. J Mater 1(3):253–261

Lin WS, Starr TL, Harris BT, Zandinejad A, Morton D (2013) Additive manufacturing technology (direct metal laser sintering) as a novel approach to fabricate functionally graded titanium implants: preliminary investigation of fabrication parameters. Int J Oral Maxillofac Implants 28(6):1490–1495

Osakada K, Shiomi M (2006) Flexible manufacturing of metallic products by selective laser melting of powder. Int J Mach Tool Manu 46(11):1188–1193

Mizutani M, Honda R, Yuda A, Komotori J, Ohmori H (2013) Effects of nanosecond laser fabrication on bioactivity of pure titanium. Procedia CIRP 5:242–246

Han G, Shen Z (2015) Microscopic view of osseointegration and functional mechanisms of implant surfaces. Mater Sci Eng C Mater Biol Appl 56:380–385

Mangano C, Piattelli A, d’Avila S et al (2010) Early human bone response to laser metal sintering surface topography: a histologic report. J oral implantol 36(2):91–96

Witek L, Marin C, Granato R et al (2012) Characterization and in vivo evaluation of laser sintered dental endosseous implants in dogs. Biomed Mater Res Part B Appl Biomater 100(6):1566–1573

Bandyopadhyay A, Espana F, Balla VK, Bose S, Ohgami Y, Davies NM (2010) Influence of porosity on mechanical properties and in vivo response of Ti6Al4V implants. Acta Biomater 6(4):1640–1648

Acknowledgments

This study was supported by a grant from Iran National Science Foundation (Project no. 95819948).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that there is no conflict of interest.

Rights and permissions

About this article

Cite this article

Hindy, A., Farahmand, F. & Tabatabaei, F.s. In vitro biological outcome of laser application for modification or processing of titanium dental implants. Lasers Med Sci 32, 1197–1206 (2017). https://doi.org/10.1007/s10103-017-2217-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10103-017-2217-7