Abstract

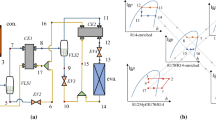

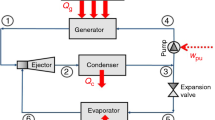

In the present study, an ejector refrigeration cycle with a flash chamber (FC) and a booster compressor is proposed to produce a 300-kW refrigeration effect for evaporator temperature varying between − 10 and 0 °C. R600a and R1234yf are considered as the working fluids. Readily available geothermal water at 95 °C is considered as the heat source. Thermodynamic and economic analyses are conducted by comparing with a vapour compression refrigeration cycle (VCRC) with a FC. It is observed that there exist optimum combinations of booster compressor pressure ratio and flash pressure ratio corresponding to the maximum mechanical COP and minimum levelized cooling cost (LCC). Both the proposed ejector refrigeration cycle and the VCRC yield better economic performance with R600a. For zero-carbon pricing and the specified range of evaporator temperature, the achievable LCC reduction with the R600a-based proposed cycle varies between 11.99 and 13.98%. The corresponding range of the achievable LCC reduction is 15.02–26.20% for a carbon price of $ 75/ton of CO2. If the geothermal water flow rate is restricted to 15 kg/s, the achievable range of LCC reductions for an R600a-based system will be 7.48–10.40% if the carbon pricing is ignored. For a reasonable carbon price, the proposed geothermal heat-driven cycle with each considered working fluid yields a much lower LCC compared to that of the conventional cycle as the annual carbon foot print of the presented cycle is much lower.

Graphical abstract

Similar content being viewed by others

Data availability

Enquiries about data availability should be directed to the authors.

Abbreviations

- \({\text{AOH}}\) :

-

Annual operating hours (h/annum)

- BCPR:

-

Booster compressor pressure ratio (dimensionless)

- \(C_{{\text{P}}}^{0}\) :

-

Basic purchase cost of equipment ($)

- \(C_{{{\text{BM}}}}\) :

-

Bare module cost ($)

- \(COP_{{\text{M}}}\) :

-

Mechanical COP (dimensionless)

- \({\text{CRF}}\) :

-

Capital recovery factor (dimensionless)

- EF:

-

Emission factor (ton of CO2/kWh)

- FPR:

-

Flash pressure ratio (dimensionless)

- \({\text{EP}}\) :

-

Electricity price ($/kWh)

- \(h\) :

-

Enthalpy (kJ/kg or J/kg)

- \({\text{LCC}}\) :

-

Levelized cooling cost ($/kWh)

- \(\dot{m}\) :

-

Refrigerant mass flow rate (kg/s)

- \(\dot{m}_{{{\text{GW}}}}\) :

-

Geothermal water mass flow rate (kg/s)

- \({\text{MF}}\) :

-

Maintenance factor (dimensionless)

- N :

-

Nozzle

- P :

-

Pressure (MPa)

- \(\dot{Q}_{{{\text{RE}}}}\) :

-

Cooling effect (kW)

- \(s\) :

-

Entropy (kJ/kg K)

- T :

-

Temperature (K)

- t :

-

Temperature (oC)

- \(U\) :

-

Overall heat transfer coefficient (W/m2 K)

- \(u\) :

-

Velocity (m/s)

- \(\dot{W}\) :

-

Input power (kW)

- \(x\) :

-

Vapour quality (dimensionless)

- \(\eta\) :

-

Efficiency

- \(\mu\) :

-

Entrainment ratio (dimensionless)

- BC:

-

Booster compressor

- Con:

-

Condenser

- D:

-

Diffuser

- EV:

-

Evaporator

- FC:

-

Flash chamber

- GW:

-

Geothermal water

- HPC:

-

High-pressure compressor

- HRU:

-

Heat recovery unit

- i:

-

Inlet

- M:

-

Mixing

- o:

-

Exit

- 1–11, 8/ :

-

State points

- BC:

-

Booster compressor

- COP:

-

Coefficient of performance

- FC:

-

Flash chamber

- ERC:

-

Ejector refrigeration cycle

References

Ahmad M, Akram W, Ahmad N, Tasneem MA, Rafiq M, Latif Z (2002) Assessment of reservoir temperatures of thermal springs of the northern areas of Pakistan by chemical and isotope geo thermometry. Geothermics 31:613–631

Besagni G, Mereu R, Leo GD, Inzoli F (2015) A study of working fluids for heat driven ejector refrigeration using lumped parameter models. Int J Refrig 58:154–171

Besagni G, Cristiani N, Croci L, Guédon GR, Inzoli F (2021) Multi-scale evaluation of ejector performances: the influence of refrigerants and ejector design. Appl Therm Eng 186:116502

Chen G, Ierin V, Volovyk O, Shestopalov K (2019) Thermodynamic analysis of ejector cooling cycles with heat-driven feed pumping devices. Energy 186:115892

Cheng Y, Wang M, Yu J (2021) Thermodynamic analysis of a novel solar-driven booster-assisted ejector refrigeration cycle. Sol Energy 218:85–94

CPLC (2017) Report of the high-level commission on carbon prices, May 29, 2017. https://static1.squarespace.com/static/54ff9c5ce4b0a53decccfb4c/t/59b7f26b3c91f1bb0de2e41a/1505227373770/CarbonPricing_EnglishSummary.pdf. Accessed 30 June 2021

Dagdas A (2007) Performance analysis and optimization of double-flash geothermal power plants. J Energy Res Technol 129:125–133

Diaz AR, Kaya E, Zarrouk SL (2016) Reinjection in geothermal fields—a worldwide review update. Renew Sustain Energy Rev 53:105–162

Gao Y, Gao X, Zhang X (2017) The 2 °C global temperature target and the evolution of the long-term goal of addressing climate change—from the united nations framework convention on climate change to the Paris agreement. Engineering 3:272–278

Guo T, Wang HX, Zhang SJ (2010) Comparative analysis of CO2-based transcritical Rankine cycle and HFC245fa-based subcritical organic Rankine cycle using low temperature geothermal source. Sci China Technol Sci 53:1638–1646

Halfaou MW, Tahar K, Ammar BB (2014) Performance analysis of a two stage vapour compression refrigeration cycle offering two cold temperatures. In: 5th international renewable energy congress; 25–27 March, Tunisia

Huang BJ, Chang JM, Wang CP, Petrenko VA (1999) A 1-D analysis of ejector performance. Int J Refrig 22:354–364

Incropera FP, Dewitt DP (2002) Fundamentals of heat and mass transfer, 5th edn. Wiley, New York

Kasperski S, Gil B (2014) Performance estimation of ejector cycles using heavier hydrocarbon refrigerants. Appl Therm Eng 71:197–203

Kenan H, Neumen EP, Lustwerk F (1950) An investigation of ejector design by analysis and experiment. J Appl Mech Trans ASME 72:299–309

Kordlar MA, Mahmoudi SMS (2017) Exergoeconomic analysis and optimization of a novelcogeneration system producing power and refrigeration. Energy Convers Manag 134:208–220

Lee HY, Park SH, Kim KH (2016) Comparative analysis of thermodynamic performance and optimization of organic flash cycle (OFC) and organic Rankine cycle (ORC). Appl Therm Eng 100:680–690

Li T, Xu Y, Wang J, Kong X, Zhu Z (2018) Poly-generation energy system driven by associated geothermal water for oilfield in high water cut stage: a theoretical study. Geothermics 76:242–252

Li T, Liu Q, Xu Y, Dong Z, Meng N, Jia Y, Qin H (2021) Techno-economic performance of multi-generation energy system driven by associated mixture of oil and geothermal water for oilfield in high water cut. Geothermics 89:101991

Liu F, Groll EA (2013) Study of ejector efficiencies in refrigeration cycles. Appl Therm Eng 52:360–370

Liu X, Zhang Y, Shen J (2017) System performance optimization of ORC-based geo-plant with R245fa under different geothermal water inlet temperatures. Geothermics 66:134–142

Liu X, Falcone G, Alimonti C (2018) A systematic study of harnessing low-temperature geothermal energy from oil and gas reservoirs. Energy 142:346–355

Mansuriya K, Patel VK, Desai NB, Vora NM (2021) A performance evaluation of the ejector refrigeration system based on thermo-economic criteria through multi-objective approach. Clean Technol Environ Policy 23:1087–1103

Martínez EH, Carlos MP, Solís JI, Avalos MM (2020) Thermodynamic simulation and mathematical model for single and double flash cycles of Cerro Prieto geothermal power plant. Geothermics 83:101713

Mazzelli M, Milazzo A (2015) Performance analysis of a supersonic ejector cycle working with R245fa. Int J Refrig 49:79–92

Meihong YU, Hongxia Z, Xinli W, Jitian H, Yanhua L (2022) Investigation on the performance of the pump-free double heat source ejector refrigeration system with R1234yf. J Therm Sci. https://doi.org/10.1007/s11630-020-1386-z

Mondal S, De S (2015) Transcritical CO2 power cycle—effects of regenerative heating using turbine bleed gas at intermediate pressure. Energy 87:95–103

Mondal S, De S (2017) Ejector based organic flash combined power and refrigeration cycle (EBOFCP&RC)—a scheme for low grade waste heat recovery. Energy 134:638–648

Mondal S, De S (2020) Performance assessment of a low-grade heat driven dual ejector vapour compression refrigeration cycle. Appl Therm Eng 179:115782

Mondal S, Alam S, De S (2018) Performance assessment of a low grade waste heat driven organic flash cycle (OFC) with ejector. Energy 163:849–862

Nebot-Andrés L, Sanchez D, Calleja-Anta D, Cabello R, Llopis R (2021) Experimental determination of the optimum intermediate and gas-cooler pressures of a commercial transcritical CO2 refrigeration plant with parallel compression. Appl Therm Eng 189:116671

PetrenkoVO VOS (2011) Theoretical study and design of a low-grade heat-driven pilot ejector refrigeration machine operating with butane and isobutane and intended for cooling of gas transported in a gas-main pipeline. Int J Refrig 34:1699–1706

Pridasawas W, Lundqvist P (2007) A year-round dynamic simulation of a solar-driven ejector refrigeration system with iso-butane as a refrigerant. Int J Refrig 30:840–850

Rashed M, Huzayyin O, Kassem MA, Kaseb S (2020) A novel thermodynamic design model of a new HFO refrigerant single phase vapor jet cooling system. Int J Refrig 110:153–167

Riaz F, Lee PS, Chou SK (2020) Thermal modelling and optimization of low-grade waste heat driven ejector refrigeration system incorporating a direct ejector model. Appl Therm Eng 167:114710

Rostamzadeh H, EbadollahiM GH, Shokri A (2019) Comparative study of two novel micro-CCHP systems based on organic Rankinecycle and Kalina cycle. Energy Convers Manag 183:210–229

Sahana C, De S, Mondal S (2021) Integration of CO2 power and refrigeration cycles with a desalination unit to recover geothermal heat in an oilfield. Appl Therm Eng 189:116744

Saleh B, AlyA A, Alsehli M, Elfasakhany A, Bassuoni MM (2020) Performance analysis and working fluid selection for single and two stages vapor compression refrigeration cycles. Processes 8(9):1017

Seyitoglu AA, Kilicarslan A (2018) Investigation of the component exergy efficiencies of a two stage vapour compression cycle. Int J Exergy 27(1):43–61

Sheykhlou H, Jafarmadar S (2016) Analysis of a combined power and ejector-refrigeration cycle based on solar energy. Iran J Sci Technol Trans Mech Eng 40:57–67

Taleghani ST, Sorin M, Gaboury S (2021) Thermo-economic analysis of heat-driven ejector system for cooling smelting process exhaust gas. Energy 220:119661

Thongtip T, Aphornratana S (2018) Development and performance of a heat driven R141b ejector air conditioner: application in hot climate country. Energy 160:556–572

Turton R, Bailie RC, Whiting WB, Shaeiwitz JA (2009) Analysis, synthesis and design of chemical processes. Prentice Hall, New Jersey

US Energy Information Administration (2021) How much carbon dioxide is produced per kilowatt-hour of U.S. electricity generation? https://www.eia.gov/tools/faqs/faq.php?id=74&t=11. Accessed 08 July 2021

Wang M, Wang J, Zhao Z, Zhao P, Dai Y (2013) Thermodynamic analysis and optimization of a solar-driven regenerative organic Rankine cycle (ORC) based on flat-plate solar collectors. Appl Therm Eng 50:816–825

Wang F, Li DY, Zhou Y (2015) Theoretical research on the performance of the transcritical ejector refrigeration cycle with various refrigerants. Appl Therm Eng 91:363–369

WBREDA. http://www.wbreda.org/geo-thermal/. Accessed 03 Feb 2023

Wood SH, Kaewsomwang P, Singharajwarapan FS (2018) Geologic framework of the Fang Hot Springs area with emphasis on structure, hydrology, and geothermal development, Chiang Mai Province, northern Thailand. Geotherm Energy 6:3. https://doi.org/10.1186/s40517-017-0087-7

Xing M, Yan G, Yu J (2015) Performance evaluation of an ejector subcooled vapor-compression refrigeration cycle. Energy Convers Manag 92:431–436

Xuehui W, Yuying Y, Edward W, Xinyue H, Neng G (2021) Prospect evaluation of low-GWP refrigerants R1233zd(E) and R1336mzz(Z) used in solar-driven ejector-vapor compression hybrid refrigeration system. J Therm Sci 30:1572–1580. https://doi.org/10.1007/s11630-020-1297-z

Yan G, Bai T, Yu J (2016) Energy and exergy efficiency analysis of solar driven ejector–compressor heat pump cycle. Sol Energy 125:243–255

Yang M-H (2016) Optimizations of the waste heat recovery system for a large marine diesel engine based on transcritical Rankine cycle. Energy 113:1109–1124

Yu J, Ren Y, Chen H, Li Y (2007) Applying mechanical subcooling to ejector refrigeration cycle for improving the coefficient of performance. Energy Convers Manag 48:1193–1199

Zheng Z, Cao J (2020) Thermodynamic and feasibility analysis of air conditioning waste heat recovery via power generation cycles. Energy Rep 6:3490

Funding

The authors have not disclosed any funding.

Author information

Authors and Affiliations

Contributions

Chitta Sahana helped in preparation, creation and/or presentation of the published work, specifically writing the initial draft Sudipta De helped in oversight and leadership responsibility for the research activity planning and execution, including mentorship external to the core team Subha Mondal helped in ideas, formulation or evolution of overarching research goals and aims; development or design of methodology and creation of models

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Sahana, C., De, S. & Mondal, S. Techno-economic assessment of low-grade geothermal heat-driven ejector refrigeration cycle with a flash chamber and a booster compressor. Clean Techn Environ Policy 26, 1089–1106 (2024). https://doi.org/10.1007/s10098-023-02662-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10098-023-02662-5