Abstract

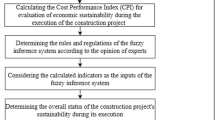

Lean and Green seeks to increase added value and reduce waste generation, while also improving environmental sustainability performance in production activities. However, no studies were found exploring the potential results by combining Lean and Green with eco-efficiency assessments in the construction sector. Therefore, this paper aimed at proposing and testing a Lean and Green approach in three steps. Step 1 was based on the Value Stream Mapping application to calculate the Value Added of construction activities; step 2 focused on the Life Cycle Assessment of evaluated construction activities, and step 3 performed an eco-efficiency assessment of construction sites to guide decision-makers on selecting more lean and sustainable construction materials and strategies. A case study was developed for a 300 m2-house construction considering two build options (reinforced concrete frame vs. light steel frame). The results affirm that light steel framing showed a value added 43% higher than the reinforced concrete in step 1, whilst having 8% less global warming potential impacts in step 2. Step 3 concluded that light steel framing was 1.38 times more eco-efficient than the concrete structure. The proposed approach can be suitable for any building system evaluation in terms of construction technologies, materials, and/or production strategies and investigations towards more sustainable production.

Graphic abstract

Similar content being viewed by others

References

Abreu MF, Alves AC, Moreira F (2017) Lean–Green models for eco-efficient and sustainable production. Energy 137:843–853. https://doi.org/10.1016/j.energy.2017.04.016

Almeida ELG, Picchi FA (2018) Relação entre construção enxuta e sustentabilidade. Ambiente Construído 18:91–109. https://doi.org/10.1590/s1678-86212018000100211

Alves A, Moreira F, Abreu F, Colombo C (2016) Sustainability, Lean and eco-efficiency symbioses. Multiple helix ecosystems for sustainable competitiveness. In: Peris-Ortiz M, Ferreira J, Farinha L, Fernandes N (eds) Innovation, technology, and knowledge management, pp 91–112. https://doi.org/10.1007/978-3-319-29677-7_7

Babalola O, Ibem EO, Ezema IC (2019) Implementation of Lean practices in the construction industry: a systematic review. Bulid Environ 148:34–43. https://doi.org/10.1016/j.buildenv.2018.10.051

Banawi A, Bilec MM (2014) A framework to improve construction processes: integrating lean, green and six sigma. Int J Constr Manag 14:45–55. https://doi.org/10.1080/15623599.2013.875266

Bento RC (2016) Análise do desempenho ambiental de estruturas de concreto armado: uso da avaliação do ciclo de vida (ACV) no processo decisório do dimensionamento. Doctoral dissertation, University of São Paulo, São Paulo, Brazil. https://doi.org/10.11606/T.102.2017.tde-23012017-101051

Bergmiller GG, Mccright PR (2009) Are Lean and Green programs synergistic? In: Proceedings of industrial engineering research annual conference. http://citeseerx.ist.psu.edu/viewdoc/download?doi=10.1.1.617.7894&rep=rep1&type=pdf. Accessed 21 August 2020

BSI - British Standards Institution (2011) EN 15978:2011: Sustainability of construction works: assessment of environmental performance buildings—Calculation method, England

Cabeza LF, Rincón L, Vilariño V, Pérez G, Castell A (2014) Life cycle assessment (LCA) and life cycle energy analysis (LCEA) of buildings and the building sector: a review. Renew Sustain Energy Rev 29:394–416. https://doi.org/10.1016/j.rser.2013.08.037

Carvajal-Arango D, Bahamón-Jaramillo S, Aristizábal-Monsalve S, Vásquez-Hernández A, Botero LFB (2019) Relationships between lean and sustainable construction: positive impacts of lean practices over sustainability during construction phase. J Clea Prod 234:1322–1337. https://doi.org/10.1016/j.jclepro.2019.05.216

Carvalho ACV, Granja AD, Silva VG (2017) A systematic literature review on integrative lean and sustainability synergies over a building’s lifecycle. Sustainability (Switzerland) 9:1156. https://doi.org/10.3390/su9071156

Cheung WM, Leong JT, Vichare P (2017) Incorporating lean thinking and life cycle assessment to reduce environmental impacts of plastic injection moulded products. J Clean Prod 167:759–775. https://doi.org/10.1016/j.jclepro.2017.08.208

Djatna T, Prasetyo D (2019) Integration of sustainable value stream mapping (sus. VSM) and life-cycle assessment (LCA) to improve sustainability performance. Int J Adv Sci Eng Inf Technol 9:1343–1997. https://doi.org/10.18517/ijaseit.9.4.9302

Dües CM, Tan KH, Lim M (2013) Green as the new Lean: how to use Lean practices as a catalyst to greening your supply chain. J Clean Prod 40:93–100. https://doi.org/10.1016/j.jclepro.2011.12.023

Estrada-González IE, Taboada-Gonzalez PA, Guerrero-García-Rojas H, Marquez-Benavides L (2020) Decreasing the environmental impact in an egg-producing farm through the application of LCA and lean tools. Appl Sci 10(4): 1352. https://doi.org/10.3390/app10041352

Evangelista PA, Kiperstok A, Torres EA, Gonçalves JP (2018) Environmental performance analysis of residential buildings in Brazil using life cycle assessment (LCA). Constr Build Mater 169:748–761. https://doi.org/10.1016/j.conbuildmat.2018.02.045

Florida R (1996) Lean and Green: the move to environmentally conscious manufacturing. Calif Manag Rev 39:80–105. https://doi.org/10.2307/41165877

Gámez-García DC, Saldaña-Márquez H, Gómez-Soberón JM, Corral-Higuera R, Arredondo-Rea SP (2019) Life cycle assessment of residential streets from the perspective of favoring the human scale and reducing motorized traffic flow from cradle to handover approach. Sustain Cities Soc 44:332–342. https://doi.org/10.1016/j.scs.2018.10.018

Garza-Reyes JA (2015) Lean and Green—a systematic review of the state-of-the-art literature. J Clean Prod 102:18–29. https://doi.org/10.1016/j.jclepro.2015.04.064

Garza-Reyes JA, Kumar V, Chaikittisilp S, Tan KH (2018) The effect of lean methods and tools on the environmental performance of manufacturing organizations. Int J Prod Econ 200:170–180. https://doi.org/10.1016/j.ijpe.2018.03.030

Grohmann MZ (1998) Redução do desperdício na construção civil: levantamento das medidas utilizadas pelas empresas de Santa Maria. In: XVIII Encontro Nacional de Engenharia de Produção

Haes HAU (1993) Applications of life cycle assessment: expectations, drawbacks and perspectives. J Clean Prod 1:131–137. https://doi.org/10.1016/0959-6526(93)90002-S

Huang A (2017) A framework and metrics for sustainable manufacturing performance evaluation at the production line, plant and enterprise levels. Doctoral Theses. Engineering College, University of Kentucky. http://uknowledge.uky.edu/me_etds/97

ISO (2006a) ISO 14040: Environmental management—life cycle assessment—principles and framework. Switzerland, Geneva

ISO (2006b) ISO14044: Environmental management—life cycle assessment—requirements and guidelines. Switzerland, Geneva

ISO (2012) ISO14045: Environmental Management—eco-efficiency assessment of product systems—principles, requirements and guidelines. Switzerland, Geneva

King AA, Lenox MJ (2001) Lean and green? An empirical examination of the relationship between lean production and environmental performance. J Prod Oper Manag 10:244–256. https://doi.org/10.1111/j.1937-5956.2001.tb00373.x

Leksic I, Stefanic N, Veza I (2020) The impact of using different lean manufacturing tools on waste reduction. Adv Prod Eng Manag. https://doi.org/10.14743/apem2020.1.351

Leme Júnior RDN, Nunes AO, Costa LBM, Silva DAL (2018) Creating value with less impact: lean, green and eco-efficiency in a metalworking industry towards a cleaner production. J Clean Prod 196:517–534. https://doi.org/10.1016/j.jclepro.2018.06.064

Litos L, Borzillo F, Patsavellas J, Cockhead D, Salonitis K (2017) Management tool design for eco-efficiency improvements in manufacturing - a case study. Proc CIRP 60:500–505. https://doi.org/10.1016/j.procir.2017.02.001

Mattos AD (2006) Como preparar orçamentos de obras: dicas para orçamentistas, estudos de caso, exemplos. Editora Pini, São Paulo

Oliveira JA, Silva DAL, Ganga GMD, Godinho Filho M, Ferreira AA, Esposto K, Ometto AR (2019) Cleaner production practices, motivators and performance in the Brazilian industrial companies. J Clean Prod 231(10):359–369. https://doi.org/10.1016/j.jclepro.2019.05.013

Pampanelli AB, Found P, Bernardes AM (2014) A Lean & Green model for a production cell. J Clean Prod 85:19–30. https://doi.org/10.1016/j.jclepro.2013.06.014

Picchi FA (2003) Oportunidades da aplicação do Lean Thinking na construção. Ambiente Construído 3:7–23

Picchi FA (2000) Lean principles and the construction main flows. In: International Group for Lean Construction, Brighton

Rezaei F, Bulle C, Lesage P (2019) Integrating building information modeling and life cycle assessment in the early and detailed building design stages. Build Environ 153:158–167. https://doi.org/10.1016/j.buildenv.2019.01.034

Rezende MO, Silva DV, Moris VAS, Silva DAL (2021) Lean & Green and the life cycle stages of constructions: literature mapping and trend analysis. J Lean Syst 6(3):38–61

Rezende MO, Linhares TM, Moris VAS, Iritani D, Silva DAL (2019) Overview of the UNEP’s eco-innovation manual application from 2016–2018 in Brazilian companies. In: VIII International Conference on life cycle assessment in Latin America, Costa Rica

Riley D, Sanvido V, Horman M, Mclaughlin M (2005) Lean and Green: the role of design-build mechanical competencies in the design and construction of green buildings. In: Construction Research Congress, San Diego, California

Rosenbaum S, Toledo M, González V (2013) Improving environmental and production performance in construction projects using value-stream mapping: case study. J Construct Eng Manag 140(2):04013045. https://doi.org/10.1061/(ASCE)CO.1943-7862.0000793

Rosenbaum S, Toledo M, Gonzalez V (2008) Green-lean approach for assessing environmental and production waste in construction. In: International Group Lean Construction, Manchester, United Kingdom

Rother M, Shook J (2000) Learning to see: value stream mapping to create value and eliminate Muda. Lean Enterprise Institute Brookline

Saieg P, Sotelino ED, Nascimento D, Caiado RGG (2018) Interactions of building information modeling, Lean and Sustainability on the architectural, engineering and construction industry: a systematic review. J Clean Prod 174:788–806. https://doi.org/10.1016/j.jclepro.2017.11.030

Salvador R, Barros MV, Santos GET, Mierlo KG, Piekarski CM, Francisco AC (2021) Towards a green and fast production system: integrating life cycle assessment and value stream mapping for decision making. Environ Impact Assess Rev 87:106519. https://doi.org/10.1016/j.eiar.2020.106519

Samant S, Prakash (2020) Achieving lean and improving sustainability through value stream mapping for complex manufacturing. MS&E 748(1): 012022. https://doi.org/10.1088/1757-899X/748/1/012022

Vinodh S, Arvind KR, Somanaathan M (2011) Tools and techniques for enabling sustainability through lean initiatives. Clean Technol Environ Policy 13:469–479. https://doi.org/10.1007/s10098-010-0329-x

Vinodh S, Ruben RB, Asokan P (2015) Life cycle assessment integrated value stream mapping framework to ensure sustainable manufacturing: a case study. Clean Technol Environ Policy 18:279–295. https://doi.org/10.1007/s10098-015-1016-8

WBCSD—World Business Council for Sustainable Development (2000b) Measuring eco-efficiency: a guide to reporting company performance. Geneva

WBCSD—World Business Council for Sustainable Development (2000a) Eco-efficiency: creating more value with less impact. Geneva

Womack J, Jones D (1996) Lean thinking: banish waste and create wealth in your Corporation. Simon and Schuster, New York

Acknowledgements

This work was supported by the Conselho Nacional de Desenvolvimento Científico e Tecnológico (CNPq) under Grants 302722/2019-0 and 406017/2018-2.

Funding

Funding was provided by Conselho Nacional de Desenvolvimento Científico e Tecnológico (BR) (Grant Nos. 302722/2019-0, 406017/2018-2).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

de Oliveira Rezende, M., Saade, M.R.M., Nunes, A.O. et al. A Lean and Green approach for the eco-efficiency assessment on construction sites: description and case study. Clean Techn Environ Policy 24, 1535–1552 (2022). https://doi.org/10.1007/s10098-021-02265-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10098-021-02265-y