Abstract

Hybrid vehicles are becoming more popular in Thailand. The battery that is used in hybrid vehicles is nickel metal hydride battery (Ni-MH). However, there is no management plan in dealing with Ni-MH batter wastes. It needs to be developed. This study applied material flow analysis (MFA) as a tool to trace nickel flow and stock in Ni-MH batteries supply chain in Thailand in order to analyze the current status of Ni-MH management and ways of improving circular economy. The authors calculated Material Circularity Indicator for a product (MCIp) and used it as an indicator of circular economy. In 2018, a total of 3414 tons of nickel in the used Ni-MH batteries were sent to Japan for recycling from Thailand. Because the efficiency of recycling was 95%, only 3243 tons of nickel were obtained in this process and sent to a battery pack manufacturing factory. The total quantity of batteries that was repacked was equivalent to 1921 tons of nickel a year. The domestic MCIp is 0.424, and the transboundary MCIp of nickel in NI-MH batteries in Thailand is 0.971, suggesting that even though looking at the global view, it has good circular system but for domestic view, Thailand is still far away from fully circularity. It would be better if Thailand had its recycling factory and did not have to ship materials to Japan for recycling. The shipment is costly and contributes to the greenhouse effect.

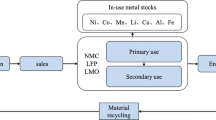

Graphical abstract

Similar content being viewed by others

Abbreviations

- \({y}_{t}\) :

-

Actual value from the serial data at the time

- \({\beta }_{0}\) :

-

Constant value of the information at the time

- \({\beta }_{1}\) :

-

Value that the article has changed when time changes 1 unit of time

- \({\widehat{y}}_{t}\) :

-

Estimated value at time

- \(n\) :

-

Number of data collected

- \(\overline{{y }_{t}}\) :

-

Average value of data collected

- R 2 :

-

Coefficient of determination

- \({MCI}_{P}\) :

-

Material Circularity Indicator of a product

- \(LFI\) :

-

Linear Flow Index

- \(V\) :

-

Virgin material (ton/year)

- \(M\) :

-

Mass of the finished product (ton/year)

- \({F}_{R}\) :

-

Fraction of feedstock derived from recycled sources

- \({F}_{U}\) :

-

Fraction of feedstock derived from reused sources

- \(W\) :

-

Overall amount of unrecoverable waste (ton/year)

- \({W}_{0}\) :

-

Amount of waste going to landfill or energy recovery (ton/year)

- \({C}_{R}\) :

-

Fraction of the mass of the product being collected for recycling at the end of its use phase

- \({C}_{U}\) :

-

Fraction of mass of the product going into component reused

- \({W}_{F}\) :

-

Quantity of waste generated to produce any recycled content used as feedstock (ton/year)

- \({E}_{F}\) :

-

Efficiency of the recycling process used to produce the recycled feedstock

- \({W}_{C}\) :

-

Quantity of waste generated in the recycling process (ton/year)

- \({E}_{C}\) :

-

Efficiency of the recycling process used for recycling the product at the end of its use phase

- \(F(X)\) :

-

Utility factor

- \(X\) :

-

Utility X

- \(L\) :

-

Life time of product (year)

- \({L}_{av}\) :

-

Industrial average life time of product (year)

References

Babarinde B, Akinlabi S, Madyira D, Ekundayo F, Adedeji P (2020) Dataset and ANN model prediction of performance of graphene nanolubricant with R600a in domestic refrigerator system. Data Brief 32:106098. https://doi.org/10.1016/j.dib.2020.106098

Brunner P, Rechberger H (2016) Handbook of material flow analysis: for environmental, resource, and waste engineers. CRC Press, Boca Raton

Calter P, Calter M (2011) Technical mathematics, 6th edn. Wiley

Cencic O, Rechberger H (2008) Material flow analysis with Software STAN. J Environ Eng Manage 18:3–7

Chang T, You S, Yu B, Yao K (2009) A material flow of lithium batteries in Taiwan. J Hazard Mater 163:910–915. https://doi.org/10.1016/j.jhazmat.2008.07.043

Department of Land Transport Thailand (2018) https://web.dlt.go.th/statistics/. Accessed 18 Febuary 2021

Desjardins J, Capitalist V (2017) Electric cars are going to mean a lot of demand for nickel. https://www.businessinsider.com/electric-car-batteries-are-going-to-drive-a-lot-of-demand-for-nickel-2017-10. Accessed 7 January 2021

Ekermo V (2009) Recycling opportunities for Li-ion batteries from hybrid electric vehicles. Chalmers University of Technology, Sweden, Department of Chemistry and Biological Engineering

Ellen Macarthur Foundation (2015) Circularity indicators an approach to measuring circularity methodology. https://www.ellenmacarthurfoundation.org/assets/downloads/insight/Circularity-Indicators_Methodology_May2015.pdf. Accessed 5 March 2021

Fetcenko M, Ovshinsky S, Reichman B, Young K, Fierro C, Koch J, Zallen A, Mays W, Ouchi T (2007) Recent advances in NiMH battery technology. J Power Sources 165:544–551. https://doi.org/10.1016/j.jpowsour.2006.10.036

Islam M, Huda N (2019) Material flow analysis (MFA) as a strategic tool in E-waste management: applications, trends and future directions. J Environ Manage 244:344–361. https://doi.org/10.1016/j.jenvman.2019.05.062

Kaewtapee C, Khetchaturat C, Bunchasak C (2011) Comparison of growth models between artificial neural netwoks and nonlinear regression analysis in Cherry Valley ducks. J Appl Poultry Res 20:421–428. https://doi.org/10.3382/japr.2010-00223

Kahn D (2015) Attacking Problems in Logarithms and Exponential Functions. Dover Publications, New York

Kurzweil P, Garche J (2017). Overview of batteries for future automobiles, pp 27–96. https://doi.org/10.1016/B978-0-444-63700-0.00002-7

LME (2018) LME Nikel. https://www.lme.com/en-GB/Metals/Non-ferrous/Nickel#tabIndex=0. Accessed 14 January 2021

Mahmud P, Huda N, Farjana S, Lang C (2019) Comparative life cycle environmental impact analysis of Lithium-Ion (LiIo) and Nickel-Methal Hydride (NiMH) Batteries. Batteries 5:22. https://doi.org/10.3390/batteries5010022

Matheys J, Timmermans JM, Van Mierlo J, Meyer S, Van den Bossche P (2009) Comparison of the environmental impact of five electric vehicle battery technologies using LCA. Int J Sustain Manufact 1:318–329. https://doi.org/10.1504/IJSM.2009.023977

Mehri M (2012) Development of artificial neural network models based on experimental data of response surface methodology to establish the nutritional requirements of digestible lysine, methionine, and threonine in broiler chicks. Poult Sci 91:3280–3285. https://doi.org/10.3382/ps.2012-02411

Milie A, Henchir J (2011) Innovative Battery Technology for Modern Hybrid Electric Vehicles, Eleventh Annual Freshman Conference. March 3, 2011. Swanson School of Engineering. University of Pittsburgh

Natalia L, Franco DP, Lois B (2016) Lithium ion battery value chain and related opportunities for Europe. Euro Commission's Sci Knowledge Service. https://doi.org/10.2760/6060

Prajapati K, Sagar R, Patel R (2014) Hybrid vehicle: a study on technology. Int J Eng Res Technol 3:1076–1082

Radhakrishna Rao C, Toutenburg H (1995) Linear models least squares and alternatives. Springer, New York

Richa K, Babbitt C, Gaustad G (2017) Eco-efficiency analysis of a lithium-ion battery waste hierarchy inspired by circular economy: LIB waste hierarchy inspired by circular economy. J Ind Ecol 2:715–730. https://doi.org/10.1111/jiec.12607

Roskill (2017). Lithium-ion batteries: Market development and the impact on raw materials. https://roskill.com/news/lithium-ion-batteries-market-development-impact-raw-materials/. Accessed 21 March 2021

Sequeira C, Pedro M (2008) Battery storage. Ciência Tecnologia Dos Materiais 20(3–4):21–30

Somvanshi S, Kumari M (2020) Comparative analysis of different vegetation indices with respect to atmospheric particulate pollution using sentinel data. Applied Computing and Geosciences 7:100032. https://doi.org/10.1016/j.acags.2020.100032

Suriyanon W, Jakrawatana N, Suriyanon N (2020) Material flow analysis of lead in lead acid batteries supply chain toward circular economy. Thai Environ Eng J 34:55–62

Taenvat M (2015) Power regression as an example of the third law of hotels in Paris: Planets. J Astrophys Aerospace Technol 3:2

Thailand Automotive Institute (2019) Active battery management business study report. Thailand. Accessed 6 Febuary 2021

Toyota PR database (2019) Toyota celebrates 10 years of success in hybrid vehicles in Thailand. https://www.toyota.co.th/prdatabase/detail/yjYX074v. Accessed 30 January 2021

UBS (2017) UBS Evidence Lab Electric Car Teardown – Disruption Ahead?, Q-Series Global Research. https://neo.ubs.com/shared/d1wkuDlEbYPjF/. Accessed 26 Febuary 2021

Urraca R, Gracia-Amillo A, Koubli E, Huld T, Trentmann J, Riihela A, Lindfors A, Palmer D, Gottschalg R, Torres F (2017) Extensive validation of CM SAF surface radiation products over Europe. Remote Sens Environ 199:171–186. https://doi.org/10.1016/j.rse.2017.07.013

Wang S, Li R, Evans A, Li F (2019) Electric vehicle load disaggregation based on limited activation matching pursuits. Energy Procedia 158:2611–2616. https://doi.org/10.1016/j.egypro.2019.02.011

Wei B (1998) Exponential Family Nonlinear Models. Springer, Heidelberg

Young K (2018) Research in nickel/metal hydride batteries 2017. Batteries 4:9. https://doi.org/10.3390/batteries4010009

Acknowledgements

We acknowledge all the support of The Department of Environmental Engineering, Faculty of Engineering Chaingmai University and Department of Environmental Engineering, Faculty of Engineering, Ratchamangkala University Technology Lanna. We are grateful to Mr John Tucker, MA in Language Testing, University of Lancaster, for kind help in the English correction.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Suriyanon, W., Jakrawatana, N. & Suriyanon, N. Material flow of nickel in nickel metal hydride batteries waste and possible circularity improvement in Thailand. Clean Techn Environ Policy 24, 887–899 (2022). https://doi.org/10.1007/s10098-021-02229-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10098-021-02229-2