Abstract

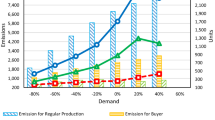

Unlike previous research, this study develops an integrated inventory model for controllable lead time with defective items, errors in inspection, and variable lead time considering sustainability. The research investigates the effect of controlling lead time and capital investment in the setup cost. We assume that the buyer receives a lot size that may contain some defective items with a known defective probability. The buyer’s inspector conducts a 100% quality inspection and may incorrectly classify a non-defective item as a defective item (type one (I) error) or incorrectly classify a defective item as a non-defective item (type two (II) error). The mathematical inventory model considering carbon emission cost is developed, and the solution procedure is designed using the heuristic algorithm to derive the optimal or near optimal solution. Finally, numerical examples and sensitivity analysis are given to illustrate the results. The results show that the defective rate, and type I type II inspection errors, have a significant impact on the shipment lot. This leads to the changes in the total cost, lead time, and the carbon emissions. Our study provides cost savings of 4.39% and carbon emission savings of 28.44%.

Graphic abstract

Similar content being viewed by others

References

Eroglu A, Ozdemir G (2007) An economic order quantity model with defective items and shortages. Int J Prod Econ 106(2):544–549

Fallahi A, Azimi-Dastgerdi M, Mokhtari H (2021) A sustainable production-inventory model joint with preventive maintenance and multiple shipments for imperfect quality items. Sci Iran. https://doi.org/10.24200/SCI.2021.55927.4475 (in press)

Goyal SK, Cárdenas-Barrón LE (2002) Note on: economic production quantity model for items with imperfect quality—a practical approach. Int J Prod Econ 77(1):85–87

Goyal SK, Huang CK, Chen KC (2003) A simple integrated production policy of an imperfect item for vendor and buyer. Prod Plan Control 14(7):596–602

Heydari J, Govindan K, Jafari A (2017) Reverse and closed loop supply chain coordination by considering government role. Transp Res Part D Transp Environ 52:379–398

Hsu JT, Hsu LF (2012) An integrated single-vendor single-buyer production-inventory model for items with imperfect quality and inspection errors. Int J Ind Eng Comput 3:703–720

Jauhari WA (2016) Integrated vendor–buyer model with defective items, inspection error and stochastic demand. Int J Math Oper Res 8(3):342–359

Jauhari WA (2018) A collaborative inventory model for vendor–buyer system with stochastic demand, defective items and carbon emission cost. Int J Logist Syst Manag 29(2):241–269

Jauhari WA, Widianto IP, Rosyidi CN (2017) A supply chain inventory model for vendor–buyer system with defective items and imperfect inspection process. Int J Math Oper Res 11(4):450–469

Khan M, Jaber MY, Bonney M (2011) An economic order quantity (EOQ) for items with imperfect quality and inspection errors. Int J Prod Econ 133(1):113–118

Khan M, Hussain M, Saber H (2017) A vendor–buyer supply chain model with stochastic lead times and screening errors. Int J Oper Res. https://doi.org/10.1504/IJOR.2017.10003467

Konstantaras I, Goyal SK, Papachristos S (2007) Economic ordering policy for an item with imperfect quality subject to the in-house inspection. Int J Syst Sci 38(6):473–482

Liao CJ, Shyu CH (1991) An analytical determination of lead time with normal demand. Int J Oper Prod Manag 11(9):72–78

Maddah B, Jaber MY (2008) Economic order quantity for items with imperfect quality: revisited. Int J Prod Econ 112(2):808–815

Öztürk H (2021) Modelling economic order quantities, considering buy and repair options for defective items, and allowing for shortages and inspection errors. J Oper Res Soc China 65:1–39

Papachristos S, Konstantaras I (2006) Economic ordering quantity models for items with imperfect quality. Int J Prod Econ 100(1):148–154

Saga RS, Jauhari WA, Laksono PW, Dwicahyani AR (2019) Investigating carbon emissions in a production-inventory model under imperfect production, inspection errors and service-level constraint. Int J Logist Syst Manag 34(1):29–55

Salameh MK, Jaber MY (2000) Economic production quantity model for items with imperfect quality. Int J Prod Econ 64(1):59–64

Tiwari S, Daryanto Y, Wee HM (2018a) Sustainable inventory management with deteriorating and imperfect quality items considering carbon emission. J Clean Prod 192:281–292

Tiwari S, Sana SS, Sarkar S (2018b) Joint economic lot sizing model with stochastic demand and controllable lead-time by reducing ordering cost and setup cost. Revista De La Real Academia De Ciencias Exactas Físicas y Naturales Serie A Matemáticas 112(4):1075–1099

Tiwari S, Kazemi N, Modak NM, Cárdenas-Barrón LE, Sarkar S (2020) The effect of human errors on an integrated stochastic supply chain model with setup cost reduction and backorder price discount. Int J Prod Econ 226:107643

Wang CH (2005) Integrated production and product inspection policy for a deteriorating production system. Int J Prod Econ 95(1):123–134

Wangsa I (2017) Greenhouse gas penalty and incentive policies for a joint economic lot size model with industrial and transport emissions. Int J Ind Eng Comput 8(4):453–480

Wangsa ID, Wee HM (2019) A vendor–buyer inventory model for defective items with errors in inspection, stochastic lead time and freight cost. Inf Syst Oper Res 57(4):597–622

Wee HM, Yu J, Chen MC (2007) Optimal inventory model for items with imperfect quality and shortage backordering. Omega 35(1):7–11

Zhu G (2021) Optimal pricing and ordering policy for defective items under temporary price reduction with inspection errors and price sensitive demand. J Ind Manag Optim. https://doi.org/10.3934/jimo.2021060

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Competing interests

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Rizky, N., Wangsa, I.D., Jauhari, W.A. et al. Managing a sustainable integrated inventory model for imperfect production process with type one and type two errors. Clean Techn Environ Policy 23, 2697–2712 (2021). https://doi.org/10.1007/s10098-021-02194-w

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10098-021-02194-w