Abstract

Thermochemical conversion is a promising technology to generate producer gas (PG) from different types of agroforestry biomass residues. To use an existing open-core biomass gasifier for different feedstocks available in a agroforestry region, its viability must be studied systematically. Cocoa pod husk (CPH) is one of the promising agricultural wastes, widely available in tropical farmlands of hilly regions. In this study, a commercial 115 kWth biomass gasifier is used in both numerical and experimental methods to find the potential of CPH as a feedstock. The moisture of CPH is varied from 5 to 25%, and the performance of gasifier is investigated for ER between 0.20 and 0.40. The results show that compositions of CO, H2 and CH4 in PG are 20–24%, 12.0–16.5% and 2.0–3.2%, respectively, for the tested conditions. The best equivalence ratio and moisture content are identified as 0.25 and 5%, respectively. The calorific value, conversion efficiency and cold gas efficiency are found as 6.13 MJ/Nm3, 82% and 68%, respectively. The predicted performance parameters and temperature distribution are compared with experimental values and literature. Thus, CPH is identified as a promising feedstock for an open-core gasifier.

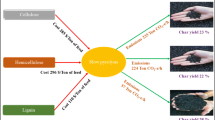

Graphic abstract

Similar content being viewed by others

Abbreviations

- A r :

-

Arrhenius rate (s−1)

- CCE:

-

Carbon conversion efficiency (%)

- CFD:

-

Computational fluid dynamics

- CG:

-

Constituent gases

- CGE:

-

Cold gas efficiency (%)

- CPH:

-

Coco Pod Husk

- CV:

-

Calorific Value (MJ Nm−3)

- CZ:

-

Combustion zone

- E a :

-

Activation energy (J k mol−1)

- ER:

-

Equivalence ratio

- PG:

-

Producer gas

- PZ:

-

Pyrolysis zone

- RMS:

-

Root mean square

- RZ:

-

Reduction zone

- \(C_{x\varepsilon }\) :

-

Model constants

- \(D_{i,m}\) :

-

Mass diffusion coefficient for species ‘i’ in the mixture (m2 s−1)

- \(\vec{F}\) :

-

Body forces (Nm−3)

- \(\vec{g}\) :

-

Acceleration due to gravity (ms−2)

- \(G_{b}\) :

-

Buoyancy turbulence kinetic energy (m2 s2)

- \(G_{{\text{k}}}\) :

-

Gradient turbulence kinetic energy (m2 s2)

- \(\overrightarrow {{J_{i} }}\) :

-

Diffusion flux of species i

- P :

-

Static pressure (Pa)

- \(R_{{i{\text{r}}}}\) :

-

Homogeneous reaction rate of species i (kg m−3 s−1)

- \({\text{R}}_{{{\text{i}},{\text{r}}}}\) :

-

Homogeneous reaction rate (kg m−3 s−1)

- \(S_{h}\) :

-

Source term (Wm−1)

- \(S_{k} ,S_{e}\) :

-

User-defined source terms

- S m :

-

MASS added to the phase (kg)

- \(\vec{v}\) :

-

Velocity (ms−1)

- Y i :

-

Mass fraction of the species i (%)

- Y m :

-

Overall dissipation turbulence rate

- \({\uprho }\) :

-

Density (kg m−3)

- \({\upmu }\) :

-

Dynamic viscosity (kg m−1 s−1)

- \({\upvarepsilon }\) :

-

Turbulent dissipation rate (m2 s−3)

- k :

-

Turbulent kinetic energy (m2 s2)

- \({\upsigma }_{{\text{k}}}\) :

-

Turbulent Prandtl number

- \({\uplambda }_{{{\text{eff}}}}\) :

-

Effective conductivity

References

Afoakwa EO, Paterson A, Fowler M (2007) Factors influencing rheological and textural qualities in chocolate–a review. Trends Food Sci Technol 18:290–298. https://doi.org/10.1016/j.tifs.2007.02.002

Andrew S, John MK, Lawrence JS, James S, Shaoping S (2010) CFD simulation of entrained- flow coal gasification: coal particle density/size fraction effects. Powder Technol 203:98–108. https://doi.org/10.1016/j.powtec.2010.03.029

Atnaw SM, Sulaiman SA, Yusup S (2014) Influence of fuel moisture content and reactor temperature on the calorific value of syngas resulted from gasification of oil palm fronds. The Sci World J 14:1–9. https://doi.org/10.1155/2014/121908

Augustine MA, Sekhar SJ (2019) Improvement in the calorific value of producer gas from rice husk with addition of spent tea waste as secondary fuel. Energy Fuels 33:12492–12498. https://doi.org/10.1021/acs.energyfuels.9b03052

Awais M, Li W, Munir A, Omar MM, Ajmal M (2020) Experimental investigation of downdraft biomass gasifier fed by sugarcane bagasse and coconut shells. Biomass Convers Biorefin. https://doi.org/10.1007/s13399-020-00690-5

Bhavanam A, Sastry RC (2011) Biomass gasification processes in downd raft fixed bed reactors: a review. Int J Chem Eng Appl 2:425–433

Brammer JG, Bridgwater AV (2002) The influence of feedstock drying on the performance and economics of a biomass gasifier–engine CHP system. Biomass Bioenergy 22:271–281. https://doi.org/10.1016/S0961-9534(02)00003-X

Beg MS, Ahmad S, Jan K, Bashir K (2017) Status, supply chain and processing of cocoa-a review. Trends Food Sci Technol 66:108–116. https://doi.org/10.1016/j.tifs.2017.06.007

Chun YN, Song HG (2019) Microwave-enhanced gasification of sewage sludge waste. Environ Eng Res 24:591–599. https://doi.org/10.4491/eer.2018.324

Dahunsi SO, Osueke CO, Olayanju TMA, Lawal AI (2019) Co-digestion of Theobroma cacao (Cocoa) pod husk and poultry manure for energy generation: effects of pretreatment methods. Bioresour Technol 283:229–241. https://doi.org/10.1016/j.biortech.2019.03.093

Directorate of Cashewnut & Cocoa Development (DCCD) (2018). https://dccd.gov.in/Content.aspx?mid=1072&tid=1

Fletcher DF, Haynes BS, Christo FC, Joseph SD (2000) A CFD based combustion model of an entrained flow biomass gasifier. Appl Math Model 24:165–182. https://doi.org/10.1016/S0307-904X(99)00025-6

Gao N, Li A (2008) Modeling and simulation of combined pyrolysis and reduction zone for a downdraft biomass gasifier. Energy Convers Manag 49:3483–3490. https://doi.org/10.1016/j.enconman.2008.08.002

Gerun L, Paraschiv M, Vijeu R, Bellettre J, Tazerout M, Gøbel B, Henriksen U (2008) Numerical investigation of the partial oxidation in a two-stage downdraft gasifier. Fuel 87:1383–1393. https://doi.org/10.1016/j.fuel.2007.07.009

Guangul FM, Sulaiman SA, Ramli A (2014) Study of the effects of operating factors on the resulting producer gas of oil palm fronds gasification with a single throat downdraft gasifier. Renew Energ 72:271–283. https://doi.org/10.1016/j.renene.2014.07.022

Holman JP (2000) Experimental methods for engineers, 7th edn. McGraw Hill Publishers, New York

Huchon V, Pinta F, Commandré JM, Van De Steene L (2020) How electrical engine power load and feedstock moisture content affect the performance of a fixed bed gasification genset. Energy 197:117144. https://doi.org/10.1016/j.energy.2020.117144

Jain AK, Goss JR (2000) Determination of reactor scaling factors for throatless rice husk gasifier. Biomass Bioenergy 18:249–256. https://doi.org/10.1016/S0961-9534(99)00083-5

Jayah TH, Aye L, Fuller RJ, Stewart DF (2003) Computer simulation of a downdraft wood gasifier for tea drying. Biomass Bioenergy 25:459–469. https://doi.org/10.1016/S0961-9534(03)00037-0

Keche AJ, Gaddale APR, Tated RG (2015) Simulation of biomass gasification in downdraft gasifier for different biomass fuels using ASPEN PLUS. Clean Technol Environ Policy 17:465–473. https://doi.org/10.1007/s10098-014-0804-x

Kim MH, Jeong IT, Park SB, Kim JW (2019) Analysis of environmental impact of activated carbon production from wood waste. Environ Eng Res 24:117–126. https://doi.org/10.4491/eer.2018.104

Kumar SS, Pitchandi K, Natarajan E (2008) Modeling and simulation of down draft wood gasifier. J Appl Sci 8:271–279. https://doi.org/10.3923/jas.2008.271.279

Kumar A, Kumar N, Baredar P, Shukla A (2015) A review on biomass energy resources, potential, conversion and policy in India. Renew Sust Energ Rev 45:530–539. https://doi.org/10.1016/j.rser.2015.02.007

Kumar U, Paul MC (2020) Sensitivity analysis of homogeneous reactions for thermochemical conversion of biomass in a downdraft gasifier. Renew Energ 151:332–341. https://doi.org/10.1016/j.renene.2019.11.025

Lee SW, Kim SB, Lee KW, Choi CS (1999) Catalytic gasification of rice straw at low temperature. Environ Eng Res 4:293–300

Magnussen BF, Hjertager BH (1976) On mathematical models of turbulent combustion with emphasis on soot formation and combustion. In: 16th international symposium on combustion, Combustion Institute, Pittsburgh.

Mashayak SY (2009) CFD modeling of plasma thermal reactor for waste treatment. Mechanical Engineering, Purdue University, West Lafayette, Indiana, Master of Science

Masmoudi MA, Halouani K, Sahraoui M (2017) Comprehensive experimental investigation and numerical modeling of the combined partial oxidation-gasification zone in a pilot downdraft air blown gasifier. Energy Convers Manag 144:34–52. https://doi.org/10.1016/j.enconman.2017.04.040

Mathimani T, Baldinelli A, Rajendran K, Prabakar D, Matheswaran M, van Leeuwen RP, Pugazhendhi A (2019) Review on cultivation and thermochemical conversion of microalgae to fuels and chemicals: process evaluation and knowledge gaps. J Clean Prod 208:1053–1064. https://doi.org/10.1016/j.jclepro.2018.10.096

Murugan PC, Sekhar SJ (2017) Species-Transport CFD model for the gasification of rice husk (Oryza Sativa) using downdraft gasifier. Comput Electron Agric 139:33–40. https://doi.org/10.1016/j.compag.2017.05.004

Murugan PC, Sekhar SJ (2017) Numerical studies to predict the impact of air nozzle position and inclination on the performance of downdraft gratifier. J Appl Fluid Mech 10:947–955. https://doi.org/10.18869/acadpub.jafm.73.238.26446

Murugan PC, Joseph Sekhar S (2017) Numerical simulation of imbert biomass gasifier to select the feedstock available in remote areas. Environ Prog Sustain Energy 36:708–716. https://doi.org/10.1002/ep.12485

Nakod PR (2013) CFD modeling and validation of oxy-fired and air-fired entrained flow gasifiers. Int J Chem Phys Sci 2:28–40

Ngamsidhiphongsa N, Ponpesh P, Shotipruk A, Arpornwichanop A (2020) Analysis of the Imbert downdraft gasifier using a species-transport CFD model including tar-cracking reactions. Energy Convers Manag 213:112808. https://doi.org/10.1016/j.enconman.2020.112808

Nisamaneenate J, Atong D, Sornkade P, Sricharoenchaikul V (2015) Fuel gas production from peanut shell waste using a modular downdraft gasifier with the thermal integrated unit. Renew Energ 79:45–50. https://doi.org/10.1016/j.renene.2014.09.046

Nouni MR, Mullick SC, Kandpal TC (2008) Providing electricity access to remote areas in India: an approach towards identifying potential areas for decentralized electricity supply. Renew Sust Energ Rev 12:1187–1220. https://doi.org/10.1016/j.rser.2007.01.008

Oddoye EO, Agyente-Badu CK, Gyedu-Akoto E (2010) Cocoa and its by-products: Identification and utilization. Chocolate in health and nutrition 7:23–38. https://doi.org/10.1007/978-1-61779-803-0_3

Plis P, Wilk RK (2011) Theoretical and experimental investigation of biomass gasification process in a fixed bed gasifier. Energy 36:3838–3845. https://doi.org/10.1016/j.energy.2010.08.039

Pode R, Diouf B, Pode G (2015) Sustainable rural electrification using rice husk biomass energy: a case study of Cambodia. Renew Sust Energ Rev 44:530–542. https://doi.org/10.1016/j.rser.2015.01.018

Poveda-Giraldo JA, Cardona Alzate CA (2020) Biorefinery potential of Eucalyptus grandis to produce phenolic compounds and biogas. Can J For Res. https://doi.org/10.1139/cjfr-2020-0201

Prasad L, Kumar SBLV (2015) Thermal degradation and gasification characteristics of Tung Shells as an open top downdraft wood gasifier feedstock. Clean Technol Environ Policy 17:1699–1706. https://doi.org/10.1007/s10098-014-0891-8

Prasertcharoensuk P, Hernandez DA, Bull SJ, Phan AN (2018) Optimization of a throat downdraft gasifier for hydrogen production. Biomass Bioenergy 116:216–226. https://doi.org/10.1016/j.biombioe.2018.06.019

Pugazhendhi A, Alagumalai A, Mathimani T, Atabani AE (2020) Optimization, kinetic and thermodynamic studies on sustainable biodiesel production from waste cooking oil: an Indian perspective. Fuel 273:117725. https://doi.org/10.1016/j.fuel.2020.117725

Puig-Arnavat M, Bruno JC, Coronas A (2010) Review and analysis of biomass gasification models. Renew Sust Energ Rev 14:2841–2851. https://doi.org/10.1016/J.RSER.2010.07.030

Ravi IS, Anders B, Mikk H (2013) CFD modeling to study fluidized bed combustion and gasification. Appl Therm Eng 52:585–614. https://doi.org/10.1016/j.applthermaleng.2012.12.017

Serrano C, Monedero E, Lapuerta M, Portero H (2011) Effect of moisture content, particle size and pine addition on quality parameters of barley straw pellets. Fuel Process Technol 92:699–706. https://doi.org/10.1016/j.fuproc.2010.11.031

Sheth PN, Babu BV (2009) Experimental studies on producer gas generation from wood waste in a downdraft biomass gasifier. Bioresour Technol 100:3127–3133. https://doi.org/10.1016/j.biortech.2009.01.024

Sikarwar VS, Zhao M, Clough P, Yao J, Zhong X, Memon MZ, Shah N, Anthony EJ, Fennell PS (2006) An overview of advances in biomass gasification. Energy Environ Sci 9:2939–2977. https://doi.org/10.1039/C6EE00935B

Singh RN, Jena U, Patel JB, Sharma AM (2006) Feasibility study of cashew nut shells as an open core gasifier Feedstock. Renew Energ 31:481–487. https://doi.org/10.1016/j.renene.2005.04.010

Singh VC, Sekhar SJ (2016) Performance studies on a downdraft biomass gasifier with blends of coconut shell and rubber seed shell as feedstock. Appl Therm Eng 97:22–27. https://doi.org/10.1016/j.applthermaleng.2015.09.099

Sulaiman SA, Karim MF, Nazmi M, Moni Z, Atnaw SM (2013) On gasification of different tropical plant-based biomass materials. Asian J Sci Res 6:245–253. https://doi.org/10.3923/ajsr.2013.245.253

Susastriawan AA, Saptoadi H, Purnomo, (2018) Design and experimental study of pilot scale throat-less downdraft gasifier fed by rice husk and wood sawdust. Int J Sustain Energy 37:873–885. https://doi.org/10.1080/14786451.2017.1383992

Tun MM, Juchelková D (2019) Estimation of greenhouse gas emissions: an alternative approach to waste management for reducing the environmental impacts in Myanmar. Environ Eng Res 24:618–629. https://doi.org/10.4491/eer.2018.364

Venkatesh G, Reddy PR, Kotari S (2017) Generation of producer gas using coconut shells and sugar cane bagasse in updraft gasifier. Mater Today 4:9203–9209. https://doi.org/10.1016/j.matpr.2017.07.278

Vriesmann LC, Amboni RDMC, Petkowicz CLO (2011) Cacao pod husks (Theobroma cacao L.): Composition and hot-water-soluble pectins. Ind Crops Prod 34:1173–1181. https://doi.org/10.1016/j.indcrop.2011.04.004

Vyas DK, Singh RN (2007) Feasibility study of Jatropha seed husk as an open core gasifier feedstock. Renew Energ 32:512–517. https://doi.org/10.1016/j.renene.2006.06.006

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Gunasekaran, A.P., Chockalingam, M.P., Padmavathy, S.R. et al. Numerical and experimental investigation on the thermochemical gasification potential of Cocoa pod husk (Theobroma Cacoa) in an open-core gasifier. Clean Techn Environ Policy 23, 1603–1615 (2021). https://doi.org/10.1007/s10098-021-02051-w

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10098-021-02051-w