Abstract

In recent years, the industrialization of construction has been promoted to achieve sustainable development within the construction industry; accordingly, prefabrication technology has been utilized substantially. Due to enormous carbon emission reduction pressure, the carbon-reducing potential of prefabrication has attracted widespread interest. To deepen the current understanding of the carbon emission performance of prefabrication, this study investigates the differences in CO2 emissions between the prefabricated and conventional construction methods and the effect of the prefabrication rate on building carbon emissions. A quantitative model is established based on life-cycle assessment (LCA) to calculate the cradle-to-site CO2 emissions of the two construction methods. The LCA model is then parameterized to simulate the cradle-to-site CO2 emissions at varying prefabrication rates. The simulation is conducted based on three scenarios, i.e., some slabs and staircases are prefabricated, all transverse members are prefabricated, and all components are prefabricated. Two sample buildings in China, where housing industrialization has developed rapidly, are used for a preliminary examination. The results show that the conventional building produces 185.13 kgCO2/m2, whereas the prefabricated building produces 151.84 kgCO2/m2, which is approximately 18% lower than the former value. Additionally, the CO2 emissions do not necessarily decrease with an increase in the prefabrication rate. The building with some prefabricated slabs and staircases produces the least CO2 emissions, and the building with the highest prefabrication rate still produces less CO2 emissions than the conventional building. Moreover, as the prefabrication rate increases, the carbon emissions during the construction cycle present a shift towards manufacturing and transportation. Therefore, adopting prefabrication technology contributes to significant environmental benefits for reducing CO2 emissions; the optimal prefabrication rate can be chosen according to the demand. Carbon reduction in manufacturing and transportation should be a new focus.

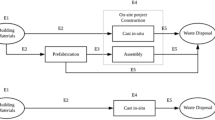

Graphic abstract

Similar content being viewed by others

References

Atmaca A, Atmaca N (2015) Life cycle energy (LCEA) and carbon dioxide emissions (LCCO2A) assessment of two residential buildings in Gaziantep, turkey. Energy Build 102:417–431. https://doi.org/10.1016/j.enbuild.2015.06.008

Bullard CW, Penner PS, Pilati DA (1978) Net energy analysis: handbook for combining process and input-output analysis. Resour Energy 1(3):267–313. https://doi.org/10.1016/0165-0572(78)90008-7

Cao X, Li X, Zhu Y, Zhang Z (2015) A comparative study of environmental performance between prefabricated and traditional residential buildings in China. J Clean Prod 109:131–143. https://doi.org/10.1016/j.jclepro.2015.04.120

Carvalho MDG, Bonifacio M, Dechamps P (2011) Building a low carbon society. Energy 36(4):1842–1847. https://doi.org/10.1016/j.energy.2010.09.030

Cheng FF (2013) The research of housing industrialization promoting mechanism. J Anhui Inst Archit Ind 21(3):61–66. https://doi.org/10.3969/j.issn.1006-4540.2013.03.016

Chou JS, Yeh KC (2015) Life cycle carbon dioxide emissions simulation and environmental cost analysis for building construction. J Clean Prod 101:137–147. https://doi.org/10.1016/j.jclepro.2015.04.001

Crowther P (1999) Design for disassembly to recover embodied energy. In: The 16th international conference on passive and low energy architecture

Dong YH, Ng ST (2015) A life cycle assessment model for evaluating the environmental impacts of building construction in Hong Kong. Build Environ 89:183–191. https://doi.org/10.1016/j.buildenv.2015.02.020

Dong YH, Ng ST, Kwan AHK, Wu SK (2015) Substituting local data for overseas life cycle inventories-a case study of concrete products in Hong Kong. J Clean Prod 87(1):414–422. https://doi.org/10.1016/j.jclepro.2014.10.005

Du Q, Wu M, Xu YD, Lu XR, Bai LB, Yu M (2018a) Club convergence and spatial distribution dynamics of carbon intensity in China’s construction industry. Nat Hazards. https://doi.org/10.1007/s11069-018-3400-2

Du Q, Xu YD, Wu M, Sun Q, Bai LB, Yu M (2018b) A network analysis of indirect carbon emission flows among different industries in China. Environ Sci Pollut Res 25(24):24469–24487. https://doi.org/10.1007/s11356-018-2533-x

Faludi J, Lepech MD, Loisos G (2012) Using life cycle assessment methods to guide architectural decision-making for sustainable prefabricated modular buildings. J Green Build Summer 7(3):151–170. https://doi.org/10.3992/jgb.7.3.151

Hong J, Shen GQ, Mao C, Li Z, Li K (2016) Life-cycle energy analysis of prefabricated building components: an input–output-based hybrid model. J Clean Prod 112:2198–2207. https://doi.org/10.1016/j.jclepro.2015.10.030

Intergovernmental Panel on Climate Change (IPCC) (2007) IPCC fourth assessment report: climate change 2007 (AR4), Working Group I: The Physical Science Basis

Jaillon L, Poon CS, Chiang YH (2009) Quantifying the waste reduction potential of using prefabrication in building construction in Hong Kong. Waste Manag 29(1):309–320. https://doi.org/10.1016/j.wasman.2008.02.015

Ji Y, Li K, Liu G, Shrestha A, Jing J (2018) Comparing greenhouse gas emissions of precast in situ and conventional construction methods. J Clean Prod 173:124–134. https://doi.org/10.1016/j.jclepro.2016.07.143

Joshi S (1999) Product environmental life-cycle assessment using input-output techniques. J Ind Ecol 3(2–3):95–120. https://doi.org/10.1162/108819899569449

Kamali M, Hewage K (2016) Life cycle performance of modular buildings: a critical review. Renew Sustain Energy Rev 62:1171–1183. https://doi.org/10.1016/j.rser.2016.05.031

Lu W, Yuan H (2013) Investigating waste reduction potential in the upstream processes of offshore prefabrication construction. Renew Sustain Energy Rev 28(8):804–811. https://doi.org/10.1016/j.rser.2013.08.048

Mao C, Shen Q, Shen L, Tang L (2013) Comparative study of greenhouse gas emissions between off-site prefabrication and conventional construction methods: two case studies of residential projects. Energy Build 66(5):165–176. https://doi.org/10.1016/j.enbuild.2013.07.033

Moncaster AM, Symons KE (2013) A method and tool for ‘cradle to grave’ embodied carbon and energy impacts of UK buildings in compliance with the new TC350 standards. Energy Build 66(11):514–523. https://doi.org/10.1016/j.enbuild.2013.07.046

Ng T.K., & Kwok S.M. (2013) Carbon emission estimation-A design verification tool for new public housing developments in Hong Kong. in HKU-HKHA International Conference 2013, Hong Kong

Pons O, Wadel G (2011) Environmental impacts of prefabricated school buildings in Catalonia. Habitat Int 35(4):553–563. https://doi.org/10.1016/j.habitatint.2011.03.005

Salzer C, Wallbaum H, Ostermeyer Y, Kono J (2017) Environmental performance of social housing in emerging economies: life cycle assessment of conventional and alternative construction methods in the Philippines. Int J Life Cycle Assess 22:1785. https://doi.org/10.1007/s11367-017-1362-3

Sarat Chandra T, Maneesh Kumar M, Mukherji S, Chauhan VS, Sarada R, Mudliar SN (2018) Comparative life cycle assessment of microalgae-mediated CO2 capture in open raceway pond and airlift photobioreactor system. Clean Technol Environ Policy 20(10):2357–2364. https://doi.org/10.1007/s10098-018-1612-5

SETAC-Europe (1993) Life Cycle Assessment and conceptually related programs summary (Report of the SETAC-Europe Working Group). SETAC-Europe, Brussels

Suh S, Lenzen M, Treloar GJ, Hondo H, Horvath A, Huppes G et al (2004) System boundary selection in life-cycle inventories using hybrid approaches. Environ Sci Technol 38(3):657–664. https://doi.org/10.1021/es0263745

Švajlenka J, Kozlovská M (2016) Transport costs of prefab wood and brick construction-comparative study. Czasopismo Techniczne, Budownictwo Zeszyt 1(6):123–129. https://doi.org/10.4467/2353737XCT.16.070.5419

Švajlenka J, Kozlovská M (2018) Houses based on wood as an ecological and sustainable housing alternative—case study. Sustainability 10(5):1502. https://doi.org/10.3390/su10051502

Švajlenka J, Kozlovská M, Pošiváková T (2018) Analysis of selected building constructions used in industrial construction in terms of sustainability benefits. Sustainability 10(12):4394. https://doi.org/10.3390/su10124394

Tam VWY, Tam CM, Zeng SX, Ng WCY (2007) Towards adoption of prefabrication in construction. Build Environ 42(10):3642–3654. https://doi.org/10.1016/j.buildenv.2006.10.003

Treloar GJ (1997) Extracting embodied energy paths from input–output tables: towards an input–output-based hybrid energy analysis method. Econ Syst Res 9(4):375–391. https://doi.org/10.1080/09535319700000032

Tumminia G, Guarino F, Longo S, Ferraro M, Cellura M, Antonucci V (2018) Life cycle energy performances and environmental impacts of a prefabricated building module. Renew Sustain Energy Rev 92:272–283. https://doi.org/10.1016/j.rser.2018.04.059

UNEP (2009) Buildings and climate change-summary for decision-makers. UNEP DTIE, Sustainable Consumption and Production Branch, 15 Rue de Milan, 75441 Paris CEDEX 09, France

Wang Y (2016) Whole life cycle carbon emissions research of industrialized precast construction. Doctoral dissertation, Southeast University, Nanjing

Wang JJ, Zhao W, Wang SL (2014) Study on calculation methods of carbon emissions of buildings during the construction. Build Sci 30(2):8–12. https://doi.org/10.13614/j.cnki.11-1962/tu.2014.02.002

Wang J, Zhao JD, Hu ZY (2016) Review and thinking on development of building industrialization in China. China Civ Eng J 43(5):1–8. https://doi.org/10.15951/j.tmgcxb.2016.05.001

Ye, B, Lu Q, Li J, Chang K (2011) Coal power GHG emission intensity model and its application. J Harb Univ Sci Technol 16(5):125–130. https://doi.org/10.15938/j.jhust.2011.05.014

Ye HW (2016) Thinking and countermeasure of new type construction industrialization. J Eng Manag 30(2):1–6. https://doi.org/10.13991/j.cnki.jem.2016.02.001

Yin SC (2012) Study of life-cycle carbon emissions in buildings. Doctoral dissertation, Harbin Institute of Technology, Heilongjiang

Zhang T (2013) Research on CO2 emission accounting model and evaluating system of low-carbon residential building based on LCA. Doctoral dissertation, Anhui University of Technology, Anhui

Zhang X, Wang F (2015) Life-cycle assessment and control measures for carbon emissions of typical buildings in china. Build Environ 86:89–97. https://doi.org/10.1016/j.buildenv.2015.01.003

Zhang X, Wang F (2016a) Hybrid input-output analysis for life-cycle energy consumption and carbon emissions of china’s building sector. Build Environ 104:188–197. https://doi.org/10.1016/j.buildenv.2016.05.018

Zhang Z, Wang B (2016b) Research on the life-cycle CO2 emission of China’s construction sector. Energy Build 112:244–255. https://doi.org/10.1016/j.enbuild.2015.12.026

Zhang X, Shen L, Zhang L (2013) Life cycle assessment of the air emissions during building construction process: a case study in Hong Kong. Renew Sustain Energy Rev 17(1):160–169. https://doi.org/10.1016/j.rser.2012.09.024

Zhang X, Skitmore M, Peng Y (2014) Exploring the challenges to industrialized residential building in China. Habitat Int 41(41):176–184. https://doi.org/10.1016/j.habitatint.2013.08.005

Acknowledgements

This work was supported by the National Social Science Foundation of China (No. 16CJY028). The authors also would like to thank Zhongtian Construction Group Co., Ltd. and Shaanxi Construction Engineering New Building Materials Co., Ltd.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Du, Q., Bao, T., Li, Y. et al. Impact of prefabrication technology on the cradle-to-site CO2 emissions of residential buildings. Clean Techn Environ Policy 21, 1499–1514 (2019). https://doi.org/10.1007/s10098-019-01723-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10098-019-01723-y