Abstract

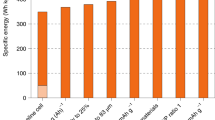

Lithium metal and silicon nanowires, with higher specific capacity than graphite, are the most promising alternative advanced anode materials for use in next-generation batteries. By comparing three batteries designed, respectively, with a lithium metal anode, a silicon nanowire anode, and a graphite anode, the authors strive to analyse the life cycle of different negative electrodes with different specific capacities and compare their cradle-to-gate environmental impacts. This paper finds that a higher specific capacity of the negative material causes lower environmental impact of the same battery. The battery with a lithium metal anode has a lower environmental impact than the battery with a graphite anode. Surprisingly, although the silicon nanowire anode has a higher specific energy than graphite, the production of a battery with silicon nanowires causes a higher environmental impact than the production of a battery with graphite. In fact, the high specific energy of silicon nanowires can decrease the environmental impact of a battery with silicon nanowires, but silicon nanowire preparation causes extremely high emissions. Therefore, batteries with lithium metal anodes are the most environmentally friendly lithium-ion batteries. Batteries with lithium metal anodes could be the next generation of environmentally friendly batteries for electric vehicles.

Similar content being viewed by others

Abbreviations

- 1,4-DB:

-

1,4-Dichlorobenzene

- BMS:

-

Battery management systems

- C:

-

Graphite

- C-A:

-

Graphite anode

- CO2 :

-

Carbon dioxide

- DoD:

-

Depth of discharge

- EVs:

-

Electric vehicles

- FDP:

-

Fossil depletion potential

- Fe:

-

Iron

- FEP:

-

Freshwater and marine eutrophication

- FU:

-

Functional unit

- GWP:

-

Global warming potential

- HTP:

-

Human toxicity potential

- kg eq:

-

Kilograms equivalents

- LCA:

-

Life cycle assessment

- LFP:

-

LiFePO4

- LFP-Li:

-

Battery with LiFePO4 cathode and lithium metal anode

- Li:

-

Lithium metal

- Li-A:

-

Lithium metal anode

- LIBs:

-

Lithium-ion batteries

- Li–O2 :

-

Lithium–air battery cells

- Li–S:

-

Lithium–sulphur battery

- LNCM:

-

0.5Li2MnO3·0.5LiNi0.44Co0.25Mn0.31O2

- MDP:

-

Metal depletion potential

- MEP:

-

Marine eutrophication potential

- N:

-

Nitrogen

- N/P ratio:

-

Capacity ratio of the negative electrode to the positive electrode

- NCM:

-

Lithium nickel cobalt manganese oxide, LiNi1/3Mn1/3Co1/3O2

- NCM-C:

-

Lithium-ion battery pack with NCM cathode and graphite anode

- NCM-Li:

-

Lithium-ion battery pack with NCM cathode and lithium metal anode

- NCM-SiNWs:

-

Lithium-ion battery pack with NCM cathode and silicon nanowire anode

- P:

-

Phosphor

- PM10:

-

Particulate matter less than 10 μm in diameter

- PMF:

-

Particulate matter formation

- SiNWs:

-

Silicon nanowires

- SiNW-A:

-

Silicon nanowire anode

- SO2 :

-

Sulphur dioxide

- TAP:

-

Terrestrial acidification potential

References

Andre D, Hain H, Lamp P, Maglia F, Stiaszny B (2017) Future high-energy density anode materials from an automotive application perspective. J Mater Chem A 5:17174–17198. https://doi.org/10.1039/c7ta03108d

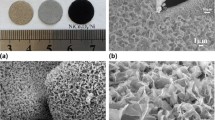

Chan CK, Peng H, Liu G, McIlwrath K, Zhang XF, Huggins RA, Cui Y (2008) High-performance lithium battery anodes using silicon nanowires. Nat Nanotechnol 3:31–35. https://doi.org/10.1038/nnano.2007.411

Cho S, Jang HY, Jung I, Liu LC, Park S (2017) Synthesis of embossing Si nanomesh and its application as an anode for lithium ion batteries. J Power Sources 362:270–277. https://doi.org/10.1016/j.jpowsour.2017.07.048

Deng YL, Li JY, Li TH, Gao XF, Yuan C (2017) Life cycle assessment of lithium sulphur battery for electric vehicles. J Power Sources 343:284–295. https://doi.org/10.1016/j.jpowsour.2017.01.036

Dunn JB, Gaines L, M. B, Sullivan J, Wang M (2014) Material and energy flows in the materials production, assembly, and end-of-life stages of the automotive lithium-ion battery life cycle. Argonne National Laboratory. https://greet.es.anl.gov/publication-lib-lca. Accessed on 5 Oct 2017

Dunn JB, Gaines L, Kelly JC, James C, Gallagher KG (2015) The significance of Li-ion batteries in electric vehicle life-cycle energy and emissions and recycling’s role in its reduction. Energy Environ Sci 8:158–168. https://doi.org/10.1039/c4ee03029j

Ecoinvent 3.3. http://www.ecoinvent.org/database. Accessed on 10 Sept 2017

Ellingsen LAW, Majeau-Bettez G, Singh B, Srivastava AK, Valoen LO, Stromman AH (2014) Life cycle assessment of a lithium-ion battery vehicle pack. J Ind Ecol 18:113–124. https://doi.org/10.1111/jiec.12072

Ellingsen LAW, Majeau-Bettez G, Stromman AH (2015) The significance of Li-ion batteries in electric vehicle life-cycle energy and emissions and recycling’s role in its reduction in energy and environmental science. J Ind Ecol 19:518–519. https://doi.org/10.1111/jiec.12309

Huijbregts MAJ et al (2017) ReCiPe2016: a harmonised life cycle impact assessment method at midpoint and endpoint level. Int J Life Cycle Assess 22:138–147. https://doi.org/10.1007/s11367-016-1246-y

ISO 14040 (2006) Environmental management—life cycle assessment—principles and framework. International Organization of Standardization, Geneva

Kang KS et al (2014) Effect of additives on electrochemical performance of lithium nickel cobalt manganese oxide at high temperature. J Power Sources 253:48–54. https://doi.org/10.1016/j.jpowsour.2013.12.024

Kushnir D, Sanden BA (2011) Multi-level energy analysis of emerging technologies: a case study in new materials for lithium ion batteries. J Clean Prod 19:1405–1416. https://doi.org/10.1016/j.jclepro.2011.05.006

Lastoskie CM, Dai Q (2015) Comparative life cycle assessment of laminated and vacuum vapour-deposited thin film solid-state batteries. J Clean Prod 91:158–169. https://doi.org/10.1016/j.jclepro.2014.12.003

Li BB, Gao XF, Li JY, Yuan C (2014) Life cycle environmental impact of high-capacity lithium ion battery with silicon nanowires anode for electric vehicles. Environ Sci Technol 48:3047–3055. https://doi.org/10.1021/es4037786

Li NW, Yin YX, Yang CP, Guo YG (2016) An artificial solid electrolyte interphase layer for stable lithium metal anodes. Adv Mater 28:1853–1858. https://doi.org/10.1002/adma.201504526

Liu S, Xiong L, He C (2014) Long cycle life lithium ion battery with lithium nickel cobalt manganese oxide (NCM) cathode. J Power Sources 261:285–291. https://doi.org/10.1016/j.jpowsour.2014.03.083

Majeau-Bettez G, Hawkins TR, Stromman AH (2011) Life cycle environmental assessment of lithium-ion and nickel metal hydride batteries for plug-in hybrid and battery electric vehicles. Environ Sci Technol 45:5454. https://doi.org/10.1021/es2015082

Manthiram A (2017) An outlook on lithium ion battery technology. ACS Central Sci 3:1063–1069. https://doi.org/10.1021/acscentsci.7b00288

Martha R, Nagaraja HS (2017) Effect of current density and electrochemical cycling on physical properties of silicon nanowires as anode for lithium ion battery. Mater Charact 129:24–30. https://doi.org/10.1016/j.matchar.2017.04.001

Matheys J, Timmermans JM, Van Mierlo J, Meyer S, Van den Bossche P (2009) Comparison of the environmental impact of five electric vehicle battery technologies using LCA. Int J Sust Manuf 1:318–329

OpenLCA. http://www.openlca.org/. Accessed on 11 Sept 2017

Peters J, Buchholz D, Passerini S, Weil M (2016) Life cycle assessment of sodium-ion batteries. Energy Environ Sci 9:1744–1751. https://doi.org/10.1039/c6ee00640j

Peters JF, Baumann M, Zimmermann B, Braun J, Weil M (2017) The environmental impact of Li-Ion batteries and the role of key parameters—a review. Renew Sustain Energy Rev 67:491–506. https://doi.org/10.1016/j.rser.2016.08.039

Wang D, Zhang W, Zheng W, Cui X, Rojo T, Zhang Q (2017) Towards high-safe lithium metal anodes: suppressing lithium dendrites via tuning surface energy. Adv Sci (Weinh) 4:1600168. https://doi.org/10.1002/advs.201600168

Wu JY, Liu P, Hu YS, Li H (2016) Calculation on energy densities of lithium ion batteries and metallic lithium ion batteries. Energy Storage Sci Technol 5:443–453

Ye H, Xin S, Yin YX, Li JY, Guo YG, Wan LJ (2017a) Stable Li plating/stripping electrochemistry realized by a hybrid Li reservoir in spherical carbon granules with 3D conducting skeletons. J Am Chem Soc 139:5916–5922. https://doi.org/10.1021/jacs.7b01763

Ye H et al (2017b) Synergism of Al-containing solid electrolyte interphase layer and Al-based colloidal particles for stable lithium anode. Nano Energy 36:411–417. https://doi.org/10.1016/j.nanoen.2017.04.056

Yu YJ, Chen B, Huang K, Wang X, Wang D (2014) Environmental impact assessment and end-of-life treatment policy analysis for Li-ion batteries and Ni–MH batteries. Int J Environ Res Pub He 11:3185–3198. https://doi.org/10.3390/ijerph110303185

Zackrisson M (2016) Life cycle assessment of long life lithium electrode for electric vehicle batteries http://ri.diva-portal.org/smash/get/diva2:1131667/FULLTEXT01.pdf. Accessed on 17 Oct 2017

Zackrisson M, Fransson K, Hildenbrand J, Lampic G, O’Dwyer C (2016) Life cycle assessment of lithium-air battery cells. J Clean Prod 135:299–311. https://doi.org/10.1016/j.jclepro.2016.06.104

Zhang CF, Yang P, Dai X, Xiong X, Zhan J, Zhang YL (2009) Synthesis of LiNi1/3Co1/3Mn1/3O2 cathode material via oxalate precursor. T Nonferrous Met Soc 19:635–641. https://doi.org/10.1016/S1003-6326(08)60325-8

Zhang R, Li NW, Cheng XB, Yin YX, Zhang Q, Guo YG (2017) Advanced micro/nanostructures for lithium metal anodes. Adv Sci (Weinh) 4:1600445. https://doi.org/10.1002/advs.201600445

Zuo TT, Wu XW, Yang CP, Yin YX, Ye H, Li NW, Guo YG (2017) Graphitized carbon fibers as multifunctional 3D current collectors for high areal capacity Li anodes. Adv Mater. https://doi.org/10.1002/adma.201700389

Acknowledgements

We are very grateful to Professor Xiaoming Ma for helpful discussions, to the editor and reviewers for their valuable comments, and to Qinhong Luo for his valuable help with plotting the data. We would like to thank James Ding and Lianyi Quan for helping the researchers to check grammar errors.

Author information

Authors and Affiliations

Corresponding author

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Wu, Z., Kong, D. Comparative life cycle assessment of lithium-ion batteries with lithium metal, silicon nanowire, and graphite anodes. Clean Techn Environ Policy 20, 1233–1244 (2018). https://doi.org/10.1007/s10098-018-1548-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10098-018-1548-9