Abstract

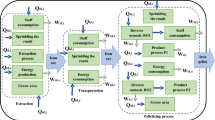

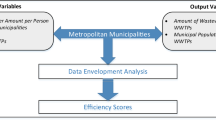

This article proposes an integrated framework for enterprise sustainability assessment by integrating enterprise input–output modeling with water pinch analysis. Firstly, material metabolism of an enterprise is investigated to establish a baseline; then, potential for resource conservation and waste minimization is evaluated. The environmental performance and economic feasibility of modifications are then assessed based on identification of key processes. Thus, the framework provides a method to connect material metabolism analysis of enterprises with the implementation of specific actions for resource conservation and waste minimization. The case of the water utilization system at Wangpo coal mine in China is used to illustrate the framework developed. Two process integration scenarios, involving direct reuse/recycle and regeneration, are presented. The corresponding revised input–output models for each scenario are illustrated.

Similar content being viewed by others

Abbreviations

- SR i :

-

Water source i

- SK j :

-

Water sink j

- F SRi,SKj :

-

Flowrate from SR i to SK j

- F SRi :

-

Flowrate of water source i

- F SKj :

-

Flowrate of water sink j

- F C,k :

-

Cumulative flowrate at concentration level k

- Σ i F SRi :

-

Total flowrate of water source i

- Σ j F SKj :

-

Total flowrate of water source i

- Σ i F SRi − Σ j F SKj :

-

Net flowrate at concentration level k

- C SRi :

-

Impurity concentration of water source i

- C SKj :

-

Impurity concentration limit of water sink j

- C k :

-

Concentration level k of cascade table

- Δm k :

-

Impurity load in each concentration interval k

- Cum.Δm k :

-

Cumulative impurity load at concentration level k

References

Agrawal R, Sikdar SK (2012) Energy, environment and sustainability challenges and opportunities for chemical engineers. Curr Opin Chem Eng 1(3):201–203

Albino V, Dietzenbacher E, Kühtz S (2003) Analysing materials and energy flows in an industrial district using an enterprise input–output model. Econ Syst Res 15(4):457–480

Albino V, Nicolò MD, Garavelli AC, Petruzzelli AM, Yazan DM (2007) Rural development and agro-energy supply chain. An application of enterprise input–output modelling supported by GIS. In: 16th International input–output conference, Istanbul, Turkey

Aviso KB, Tan RR, Culaba AB, Cruz JB (2011) Fuzzy input–output model for optimizing eco-industrial supply chains under water footprint constraints. J Clean Prod 19(2–3):187–196

Bandyopadhyay S (2011) Design and optimization of isolated energy systems through pinch analysis. Asia-Pac J Chem Eng 6(3):518–526

Bandyopadhyay S, Sahu GC, Foo DCY, Tan RR (2010) Segregated targeting for multiple resource networks using decomposition algorithm. AIChE J 5(32):1235–1248

Chew IML, Foo DCY, Ng DKS, Tan RR (2010a) Flowrate targeting algorithm for interplant resource conservation network. Part 1 unassisted integration scheme. Ind Eng Chem Res 49(14):6439–6455

Chew IML, Foo DCY, Tan RR (2010b) Flowrate targeting algorithm for interplant resource conservation network. Part 2: assisted integration scheme. Ind Eng Chem Res 49(14):6456–6468

Dai T (2010) Two quantitative indices for the planning and evaluation of eco-industrial parks. Resour Conserv Recycl 54(7):442–448

Diamante JAR, Tan RR, Foo DCY, Ng DKS, Aviso KB, Bandyopadhyay S (2013) A graphical approach for pinch-based source–sink matching and sensitivity analysis in carbon capture and storage systems. Ind Eng Chem Res 52(22):7211–7222

El-Halwagi MM (1997) Pollution prevention through process integration: systematic design tools. Academic Press, San Diego

El-Halwagi MM, Manousiouthakis V (1989) Synthesis of mass exchange networks. AIChE J 35(8):1233–1244

Ewing BR, Hawkins TR, Wiedmann TO, Galli A, Ertug Ercin A, Weinzettel J et al (2012) Integrating ecological and water footprint accounting in a multi-regional input–output framework. Ecol Indic 23:1–8

Finn JT (1976) Measures of ecosystem structure and function derived from analysis of flows. J Theor Biol 56(2):363–380

Foo DCY (2012) Process integration for resource conservation. CRC Press, Boca Raton

Foo DCY, Tan RR, Ng DKS (2008) Carbon and footprint-constrained energy planning using cascade analysis technique. Energy 33(10):1480–1488

Geldermann J, Treitz M, Rentz O (2006) Integrated technique assessment based on the pinch analysis approach for the design of production networks. Eur J Oper Res 171(3):1020–1032

Hendrickson CT, Lave LB, Matthews HS (2006) Environmental life cycle assessment of goods and services: an input–output approach. RFF Press, Washington, DC

Isard W, Vietorisz T (1955) Industrial complex analysis and regional development. Pap Reg Sci 1(1):227–247

Jia X, Li Z, Wang F, Foo DY, Qian Y (2015) A new graphical representation of water footprint pinch analysis for chemical processes. Clean Technol Environ Policy. doi:10.1007/s10098-015-0921-1

Kazantzi V, El-Halwagi MM (2005) Targeting material reuse via property integration. Chem Eng Prog 101(8):28–37

Klemeš JJ (2013) Handbook of Process Integration (PI): minimisation of energy and water use, waste and emissions. Woodhead Publishing, Cambridge

Klemeš JJ, Kravanja Z (2013) Forty years of heat integration: pinch analysis (PA) and mathematical programming (MP). Curr Opin Chem Eng 2(4):461–474

Kuan KC, Foo DY, Tan RR, Kumaresan S, Aziz RA (2007) Streamlined life cycle assessment of residue utilization options in Tongkat Ali (Eurycoma longifolia) water extract manufacturing process. Clean Technol Environ Policy 9(3):225–234

Kuhtz S, Zhou C, Albino V, Yazan DM (2010) Energy use in two Italian and Chinese tile manufacturers: a comparison using an enterprise input–output model. Energy 35(1):364–374

Lenzen M, Lundie S (2012) Constructing enterprise input–output tables—a case study of New Zealand dairy products. J Econ Struct 1(1):1–15

Liang S, Zhang T (2013) Investigating reasons for differences in the results of environmental, physical, and hybrid input–output models. J Ind Ecol 17(3):432–439

Liang S, Jia X, Zhang T (2011a) Three-dimensional hybrid enterprise input–output model for material metabolism analysis: a case study of coal mines in China. Clean Technol Environ Policy 13(1):71–85

Liang S, Shi L, Zhang T (2011b) Achieving dewaterization in industrial parks: a case study of the Yixing Economic Development Zone. J Ind Ecol 15(4):597–613

Liang S, Zhang T, Jia X (2012a) Clustering economic sectors in China on a life cycle basis to achieve environmental sustainability. Front Environ Sci Eng 7(1):97–108

Liang S, Zhang T, Xu Y (2012b) Comparisons of four categories of waste recycling in China’s paper industry based on physical input–output life-cycle assessment model. Waste Manag 32(3):603–612

Lin X, Polenske KR (1998) Input–output modeling of production processes for business management. Struct Change Econ Dyn 9(2):205–226

Linnhoff B, Hindmarsh E (1983) The pinch design method for heat exchanger networks. Chem Eng Sci 38(5):745–763

Ludwig J, Treitz M, Rentz O, Geldermann J (2009) Production planning by pinch analysis for biomass use in dynamic and seasonal markets. Int J Prod Res 47(8):2079–2090

Manan ZA, Tan YL, Foo DCY (2004) Targeting the minimum water flow rate using water cascade analysis technique. AIChE J 50(12):3169–3183

MEPPRC (2008) Cleaner production standard—Coal mining and processing industry. HJ446-2008. Ministry of Environmental Protection of the People’s Republic of China (in Chinese)

Ng DKS, Foo DCY, Tan RR, Tan YL (2007) Ultimate flowrate targeting with regeneration placement. Chem Eng Res Des 85(9):1253–1267

Ou X, Yan X, Zhang X (2011) Life-cycle energy consumption and greenhouse gas emissions for electricity generation and supply in China. Appl Energy 88(1):289–297

Piluso C, Huang Y, Lou HH (2008) Ecological input–output analysis-based sustainability analysis of industrial systems. Ind Eng Chem Res 47(6):1955–1966

Prakash R, Shenoy UV (2005) Targeting and design of water networks for fixed flowrate and fixed contaminant load operations. Chem Eng Sci 60(1):255–268

Shafiee S, Topal E (2010) A long-term view of worldwide fossil fuel prices. Appl Energy 87(3):988–1000

Singhvi A, Shenoy UV (2002) Aggregate planning in supply chains by pinch analysis. Chem Eng Res Des 80(6):597–605

Tan RR, Foo DCY (2007) Pinch analysis approach to carbon-constrained energy sector planning. Energy 32(8):1422–1429

Tan RR, Foo DCY, Aviso KB, Ng DKS (2009) The use of graphical pinch analysis for visualizing water footprint constraints in biofuel production. Appl Energy 86(5):605–609

Tan RR, Aviso KB, Barilea IU, Culaba AB, Cruz JB (2012a) A fuzzy multi-regional input–output optimization model for biomass production and trade under resource and footprint constraints. Appl Energy 90(1):154–160

Tan RR, Lam HL, Kasivisvanathan H, Ng DKS, Foo DCY, Kamal M et al (2012b) An algebraic approach to identifying bottlenecks in linear process models of multifunctional energy systems. Theor Found Chem Eng 46(6):642–650

Varbanov PS (2014) Energy and water interactions: implications for industry. Curr Opin Chem Eng 5:15–21

Varbanov PS, Seferlis P (2014) Process innovation through Integration approaches at multiple scales: a perspective. Clean Technol Environ Policy 16(7):1229–1234

Wan Alwi SR, Mohammad Rozali NE, Abdul-Manan Z, Klemeš JJ (2012) A process integration targeting method for hybrid power systems. Energy 44(1):6–10

Wan Alwi SR, Tin OS, Rozali NEM, Manan ZA, Klemeš JJ (2013) New graphical tools for process changes via load shifting for hybrid power systems based on Power Pinch Analysis. Clean Technol Environ Policy 15(3):459–472

Wang YP, Smith R (1994) Wastewater minimisation. Chem Eng Sci 49(7):981–1006

Wu G, Liu L-C, Han Z-Y, Wei Y-M (2012) Climate protection and China’s energy security: win–win or tradeoff. Appl Energy 97:157–163

Yazan DM, Garavelli AC, Petruzzelli AM, Albino V (2011) The effect of spatial variables on the economic and environmental performance of bioenergy production chains. Int J Prod Econ 131(1):224–233

Zhang X, Hu H, Zhang R, Deng S (2014) Interactions between China’s economy, energy and the air emissions and their policy implications. Renew Sustain Energy Rev 38:624–638

Zhelev TK (2005) On the integrated management of industrial resources incorporating finances. J Clean Prod 13(5):469–474

Acknowledgments

We thank anonymous reviewers for their constructive comments. This article is financially supported by the National Natural Science Foundation of China (Nos. 21136003 and 41101570). Data and technical assistance from the Wangpo mine are also appreciated. We thank Dr. S. Liang from University of Michigan for his technical assistance.

Author information

Authors and Affiliations

Corresponding author

Electronic supplementary material

Below is the link to the electronic supplementary material.

Supporting Information the Supporting Information provides details on (1) the conceptual structure of EIO model, (2) EIO tables for BAU scenario and new scenarios (direct reuse/recycle and regeneration), and (3) the limiting data for water cascade analysis and the results.

Rights and permissions

About this article

Cite this article

Jia, X., Li, Z., Wang, F. et al. Integrating input–output models with pinch technology for enterprise sustainability analysis. Clean Techn Environ Policy 17, 2255–2265 (2015). https://doi.org/10.1007/s10098-015-0963-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10098-015-0963-4