Abstract

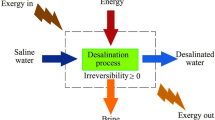

In different process industries, central site utility can produce steam at different levels. A central site utility can be coupled with a Desalination plant. In this paper, we seek the optimum integration of a central utility and a Desalination plant. Estimation of cogeneration potential prior to the design of a central utility system is important for setting targets for site fuel demand as well as steam, power, and desalinated production. Total site analysis has been applied to better understanding of the integration process. In this regard, the Total site sink/source profiles and site utility grand composite curves have been demonstrated to find best scenario for integration. Also, an accurate targeting procedure has been used. In the next step, the thermodynamic modeling and exergoeconomic and exergoenvironmental evaluation have been performed. Moreover, the exergoeconomic optimization has been applied to find optimum desalination system working point while it is integrated with central utility. Exergoenvironmental analysis has been obtained by life cycle assessment. A central utility of process plant is used as a case study to illustrate the usefulness of the proposed procedure to find optimum integrated plant. In addition, the cogeneration targeting method has been applied.

Similar content being viewed by others

Abbreviations

- A w (m/s atm):

-

Pure water permeability

- A i (m2):

-

Area of each effect

- B i (kg/s):

-

Brine mass flow rate at each effect

- B (kg/s):

-

Brine mass flow rate

- b K (mpts/kg):

-

Specific pollutant

- \( \dot{B}_{\text{F,K}} \) (mpts/s):

-

Fuel related environmental impact

- \( \dot{B}_{\text{P,K}} \) (mpts/s):

-

Product related environmental impact

- C p (kj/kg k):

-

Specific heat of water

- \( C_{{{\text{RO}} \in }} \) (ppm):

-

Salt concentration of RO input water

- D (kg/s):

-

Flow rate of desalinated water in RO plant

- D i (kg/s):

-

Mass flow rate of desalinated water at each effect

- e pump (–):

-

Exergy eliminated in the pump

- e steamin (–):

-

Exergy of input steam

- e brineinput (–):

-

Exergy of input salt water

- e desalinated (–):

-

Exergy of desalinated water

- \( \dot{E}_{\text{F,K}} \) (mpts/kj):

-

Energy of fuel related environmental impact

- \( \dot{E}_{\text{F,K}} \) (mpts/kj):

-

Energy of product related environmental impact

- \( D_{i}^{'} \) (kg/s):

-

Mass flow rate of desalinated water made in each flash box

- F (kg/s):

-

Mass flow rate of input salt water in each effect

- i eff :

-

Interest rate

- k (m/s):

-

Mass transfer coefficient for salt

- L s (kj/kg):

-

Heating steam latent heat

- m stm (kg/s):

-

.

- M f (kg/s):

-

Sea water mass flow rate

- M ev (kg/s):

-

Evaporator mass flow rate at first effect

- M cw (kg/s):

-

Cooling water mass

- M s (kg/s):

-

Heating steam mass flow rate

- N m (–):

-

Number of moles of salt

- P ev (KPa):

-

Entrained steam pressure

- P hs (KPa):

-

Heating steam pressure

- P m (KPa):

-

Motive steam pressure

- Pr (–):

-

Prantdl number

- PW ($):

-

Present worth

- PWF (–):

-

Present worth factor

- Q (kj):

-

Heat rate of heat exchanger

- R, R g [m3 atm/(mol K)]:

-

Universal gas constant

- R BD (–):

-

Working constant of boiler

- S M (kg/kmol):

-

Salt molar mass

- T 4 (°C):

-

Outlet temperature of desalination site

- T b (°C):

-

Brine temperature at each effect

- T f (°C):

-

Feed water temperature

- T cw (°C):

-

Cooling water temperature

- T s (°C):

-

Steam temperature

- T 0 (°C):

-

Ambient temperature

- T i (°C):

-

Temperature of each effect

- \( T_{{{\text{v}}_{\text{i}} }} \) (°C):

-

Temperature of steam at each effect

- \( T_{\text{i}}^{'} \) (°C):

-

Temperature at each flash box

- U e (kw/m2 °C):

-

Overall heat transfer coefficient at evaporator

- U c (kw/m2 °C):

-

Overall heat transfer coefficient at condenser

- W d (kg/s):

-

Desalinated water flow rate in MSF plant

- W s (kg/s):

-

Steam flow rate in MSF plant

- W b (kg/s):

-

Brine flow rate in MSF plant

- W r (kg/s):

-

Recycled water flow rate in MSF plant

- W f (kg/s):

-

Feed flow rate in MSF plant

- \( \varDelta P \) (KPa):

-

Transmembrane pressure

- \( \varDelta P_{\text{s}} \) (KPa):

-

Shell pressure difference

- \( \varDelta P_{\text{t}} \) (KPa):

-

Tube pressure difference

- \( \varDelta T \) (°C):

-

Temperature difference at each effect

- \( \varDelta T_{\text{c}} \) (°C):

-

Condenser temperature difference

- \( \varDelta T_{\text{lm}} \) (°C):

-

Log-mean temperature difference

- \( \varDelta T_{\text{n}} \) (°C):

-

Net temperature difference

- \( \varDelta h_{\text{gen}} \) (kj/kg k):

-

Generated enthalpy difference

- \( \varDelta h_{\text{pre}} \) (kj/kg k):

-

Blow down water enthalpy difference

- Θ (–):

-

Diffusivity

- \( \rho_{\text{b}} \) (kg/m3):

-

Density of salt

- \( \rho_{\text{m}} \) (kg/m3):

-

Density of solute

- \( \lambda_{\text{ave}} \) (kj/kg):

-

Latent heat at each effect

- \( \lambda \) (kj/kg):

-

Latent heat of steam

- \( \alpha \) (°C):

-

Average boiling point rise in recovery section

- Crf (–):

-

Capital recovery factor

- BPEi (°C):

-

Boiling point elevation

- NEAi (°C):

-

Non-equilibrium allowance

References

Alasfour FN, Darwish MA, Bin Amer AO (2005) Thermal analysis of ME-TVC + MEE desalination system. Desalination 174:39–61

Al-Azri N, Al-Thubaiti M, El-Halwagi M (2009) An algorithmic approach to the optimization of process cogeneration. Clean Technol Environ Policy 11:329–338

Al-Najem NM, Darwish MA, Youssef FA (1997) Thermo-vapor compression desalination: energy and availability analysis of single and multi-effect systems. Desalination 110:223–238

Atilhan S, Mahfouz AB, Batchelor B, Linke P, Abdel-Wahab A, Nápoles-Rivera F, Jiménez-Gutiérrez A, El-Halwagi MM (2012) A systems-integration approach to the optimization of macroscopic water desalination and distribution networks: a general framework applied to Qatar’s water resources. Clean Technol Environ Policy 14:161–171

Bamufleh HS, Ponce-Ortega JM, El-Halwagi MM (2013) Multi-objective optimization of process cogeneration systems with economic, environmental, and social tradeoffs. Clean Technol Environ Policy 15:185–197

Busch M, Mickols WE (2004) Reducing energy consumption in seawater desalination. Desalination 165:299–312

Dhole VR, Linnhoff B (1993) Total site targets for fuel, co-generation, emissions, and cooling. Comput Chem Eng 17:S101–S109

El-Dessouky HT, Ettouney HM (2002) Fundamentals of salt water desalination. Elsevier, Amsterdam

Gude VG, Nirmalakhandan N, Deng S (2010) Renewable and sustainable approaches for desalination. Renew Sustain Energy Rev 14:2641–2654

International Organization for Standardization (ISO) (2006) Environmental management—life cycle assessment. European Standard ENISO14040 and 14044, Geneva

Kalogirou S (2001) Effect of fuel cost on the price of desalination water: a case for renewables. Desalination 138:137–144

Karagiannis IC, Soldatos PG (2008) Water desalination cost literature: review and assessment. Desalination 223:448–456

Khoshgoftar Manesh MH, Amidpour M, Hamedi MH (2009) Optimization of the coupling of PWR power plant and multi stage flash desalination plant by evolutionary algorithms and thermoeconomic method. Int J Energy Res 33:77–99

Khoshgoftar Manesh MH, Ghalami H, Amidpour M, Hamedi MH (2012) A new targeting method for combined heat, power and desalinated water production in total site. Desalination 307:51–60

Khoshgoftar Manesh MH, Abadi SK, Amidpour M, Hamedi MH (2013a) A new targeting method for estimation of cogeneration potential and total annualized cost in process industries. Chem Eng Res Des 45(5):561

Khoshgoftar Manesh MH, Navid P, Amidpour M, Hamedi MH (2013b) New procedure for optimal design of cogeneration system with considering environmental impacts and total cost. Clean Technol Environ Policy 15:893–919

Khoshgoftar Manesh MH, Ghalami H, Amidpour M, Hamedi MH (2013c) Optimal coupling of site utility steam network with MED–RO desalination through total site analysis and exergoeconomic optimization. Desalination 316:42–52

Khoshgoftar Manesh MH, Janalizadeh H, Blanco Marigorta AM, Amidpour M, Hamedi MH (2014) Optimal design of integrated total site utility-multi stage flash desalination plant. Desalin Water Treat 52(7–9)

Klemes J, Dhole VR, Raissi K, Perry SJ, Puigjaner L (1997) Targeting and design methodology for reduction of fuel power and CO2 on total sites. Appl Therm Eng 17(8–10):993–1003

Koch C, Cziesla F, Tsatsaronis G (2007) Optimization of combined cycle power plants using evolutionary algorithms. Chem Eng Process 46:1151–1159

Lu YY, Hu YD, Zhang XL, Wu LY, Liu QZ (2007) Optimum design of reverse osmosis system under different feed concentration and product specification. J Membr Sci 287:219–229

Meyer L (2006) Exergiebasierte Untersuchung der Entstehung von Umweltbelastungen in Energieumwandlungsprozessen auf Komponentenebene: Exergoökologische Analyse. Ph.D. Thesis, Universität Darmstadt, Germany

Navid P, Khoshgoftar Manesh MH, Marigorta AMB (2013) Optimal design of cogeneration system based on exergoenvironmental analysis. Clean Technol Environ Policy 15:1–21

Power RB (1994) SteamJet ejector for the process industries. McGraw Hill, New York

Raissi K (1994) Total site integration. Ph.D. Thesis, The university of Manchester, Manchester, UK

Shang Z (2000) Analysis and optimisation of total site utility systems. Ph.D. Thesis, UMIST, Manchester, UK

Sorin M, Hammache A (2005) A new thermodynamic model for shaftwork targeting on total sites. Appl Therm Eng 25:961–972

Toffolo A, Lazzaretto A (2002) Evolutionary algorithms for multi-objective energetic and economic optimization in thermal system design. Energy 27:549–567

Tsatsaronis G, Morosuk T (2008) A general exergy-based method for combining a cost analysis with an environmental impact analysis: Part I—Theoretical Development. ASME

Varbanov PS (2004) Optimisation and synthesis of process utility systems, Ph.D. Thesis. Department of Process Integration. UMIST, Manchester, UK

Varbanov PS, Doyle S, Smith R (2004) Modelling and optimization of utility systems. Chem Eng Res Des 82(5):561–578

Vince F, Marechal F, Aoustin E, Breant P (2008) Multi objective optimization of RO desalination plants. Desalination 222:96–118

Author information

Authors and Affiliations

Corresponding authors

Rights and permissions

About this article

Cite this article

Janalizadeh, H., Khoshgoftar Manesh, M.H. & Amidpour, M. Exergoeconomic and exergoenvironmental evaluation of Integration of desalinations with a total site utility system. Clean Techn Environ Policy 17, 103–117 (2015). https://doi.org/10.1007/s10098-014-0765-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10098-014-0765-0