Abstract

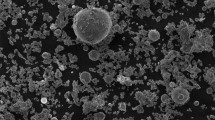

Marine concrete structures are exposed to serious attack through a number of physical and chemical deterioration processes, which deserve special attention from worldwide scientists and policy makers. This paper presents a new approach to enhance the anti-corrosion ability for concrete composed of coal combustion byproducts and blast furnace slag. Based on the experimental results, it has been concluded that the concrete composed of pozzolanic material not only provides a great chance to utilize a huge amount of industrial solid waste but also performs much better in tests of compressive strength, anti-corrosion test, and chloride penetration rather than the ordinary Portland cement concrete. The microanalysis found that needle-shaped ettringite or Ca(OH)2 crystals were presented dominantly in the microstructure of the early age hydration product, however, the amorphous C–S–H or C–A–S–H plays a more significant role in the middle to late curing age on mechanical properties and anti-corrosion abilities.

Similar content being viewed by others

References

Arya C, Xu Y (1995) Effect of cement type on chloride binding and corrosion of steel in concrete. Cem Concr Res 25:893–902

Arya C, Buenfeld N, Newman J (1990) Factors influencing chloride binding in concrete. Cem Concr Res 20(2):291–300

ASCE (2013) America’s infrastructure report card. http://www.infrastructurereportcard.org/

ASTM C1202 PA (2008) Standard test method for electrical indication of concrete’s ability to resist chloride ion penetration. Annual Book of ASTM Standards, vol 4.02. American Society for Testing and Materials, Conshohocken

ASTM C1260 (2008) Standard test method for potential alkali reactivity of aggregates (mortar bar method). American Society for Testing and Materials, Conshohocken

ASTM C1567 (2008) Standard test method for determining the potential alkali–silica reactivity of combinations of cementitious materials and aggregate (accelerated mortar bar method). American Society for Testing and Materials, Conshohocken

ASTM C666 PA (2008) Standard test method for resistance of concrete to rapid freezing and thawing. Annual Book of ASTM Standards, vol 4.02. American Society for Testing and Materials, Conshohocken

Beaton J, Stratfull R (1963) Environmental influence on corrosion of reinforcing in concrete bridge substructures. Highw Res Rec 14:60–78

Cheewaket T, Jaturapitakkul C, Chalee W (2010) Long term performance of chloride binding capacity in fly ash concrete in a marine environment. Constr Build Mater 24(8):1352–1357

Chen Q, Johnson D, Zhu L, Yuan M, Hills C (2007) Accelerated carbonation and leaching behavior of the slag from iron and steel making industry. J Univ Sci Technol Beijing 14(4):297–301

Dent Glasser LS, Kataoka N (1981) The chemistry of alkali-aggregate reaction. In: Proceedings of the 5th international conference on alkali–aggregate reaction, National Building Research Institute of the CSIR, Cape Town, South Africa, p 7, Paper S252/23

Dhir R, El-Mohr M, Dyer T (1997) Developing chloride resisting concrete using PFA. Cem Concr Res 27(11):1633–1639

Diamond S (2000) Chemistry and other characteristics of ASR gels. In: Berube MA et al (eds) Proceedings of the 11th international conference on alkali-aggregate reaction in concrete. Quebec, Canada, pp 31–40

Fernandez-Jimenez A, Garcia-Lodeiro I, Palomo A (2002) Durability of alkali-activated fly ash cementitious materials. J Mater Sci 42(9):3055–3065

Hassan Z (2001) Binding of external chloride by cement pastes. PhD thesis, Department of Building Materials, University of Toronto, Canada

Jensen O, Korzen M, Jakobsen H, Skibsted J (2000) Influence of cement constitution and temperature on chloride binding in cement paste. Adv Cem Res 12:57–64

Jiang L, Liu Z, Ye Y (2004) Durability of concrete incorporating large volumes of low-quality fly ash. Cem Concr Res 34:1467–1469

Kalyoncu R, Olson D (2000) U.S. Geological survey, fact sheet 076-01

Kanel SR, Kim J-Y, Vigneswaran S, Shim WG, Choi H (2006) Removal of arsenic(iii) from groundwater using low-cost industrial byproducts—blast furnace slag. Water Qual Res J Can 41:130–139

Kumar S (2000) Influence of water quality on the strength of plain and blended cement concretes in marine environments. Cem Concr Res 3:345–350

Lawrence C (1990) Sulphate attack on concrete. Mag Concr Res 42(153):249–264

Lewis D, Copenhagen W (1959) The corrosion of reinforcing steel in concrete in marine atmospheres. Corrosion (NACE) 15(7):382–388

Naik T, Singh S, Hossain M (1996) Enhancement in mechanical properties of concrete due to blended ash. Cem Concr Res 26(1):49–54

Nassar R, Soroushian R (2012) Strength and durability of recycled aggregate concrete containing milled glass as partial replacement for cement. Constr Build Mater 29:368–377

Poole AB (2002) Alkali–silica reactivity mechanisms of gel formation and expansion. In: Proceedings of the 9th international conference on alkali-aggregate reaction, CS 104, vol 1. Concrete Society Publications, London, pp 782–789

Shih W, Rahardianto A, Lee R, Cohen Y (2005) Morphometric characterization of calcium sulfate dehydrate (gypsum) scale on reverse osmosis membranes. J Membr Sci 252:253–263

Sun H, Jain R, Nguyen K, Zuckerman J (2010) Sialite technology—sustainable alternative to Portland cement. Clean Technol Environ Policy 12(5):503–516

Suryavanshi A, Scantlebury J, Lyon S (1996) Mechanism of Friedel’s salt formation in cements rich in tri-calcium aluminate. Cem Concr Res 26(5):717–727

Technical bulletin TB-0100 (2009) Understanding AASHTO T227 and ASTM C1202 rapid chloride permeability test. Grace construction products

Thomas M (1996) Chloride thresholds in marine concrete. Cem Concr Res 26(4):513–519

U.S. EPA (2009) Waste-partnerships-coal combustion products Partnership (C2P2). EPA, Washington, DC

Verstraete J, Khouchaf L, Bulteel D, Garcia-Diaz E, Flank AM, Tuilier MH (2004) Amorphisation mechanism of a flint aggregate during the alkali–silica reaction: X-ray diffraction and X-ray absorption XANES contributions. Cem Concr Res 34(4):581–586

Wang S, Llazamos E, Baxter L, Fonseca F (2008) Durability of biomass fly ash concrete: freezing and thawing and rapid chloride permeability tests. Fuel 87:359–364

Wang J, Niu K, Yang Z (2009) Effects of fly ash and ground granulated blast-furnaces slag on properties of high-strength concrete. Key Eng Mater 405:219–225

Wiens U, Schiessl P (1997) Chloride binding of cement paste containing fly ash. In: Justnes H (ed) Proceedings of the 10th ICCC, Goteborg, Sweden, pp 4–10

Wong G, Poole T (1987) Effect of pozzolans and slags on the sulfate resistance of hydraulic cement mortars. In: Concrete durability, Katharine and Bryant Mather international conference, ACI SP, pp 100–109

Yao Y, Sun H (2012a) A novel silica–alumina-based backfill material composed of coal refuse and fly ash. J Hazard Mater 213–214:71–82

Yao Y, Sun H (2012b) Characterization of a new silica–alumina-based backfill material utilizing large quantities of coal combustion byproducts. Fuel 97:329–336

Yao Y, Sun H (2012c) Durability and leaching analysis of a cementitious material composed of high volume coal combustion byproducts. Constr Build Mater 36:97–103

Yao Y, Sun H (2012d) Characterization of a silica–alumina based backfill material composed of coal combustion and byproducts and coal refuse. In: Proceedings of 27th international conference of solid waste technology and management, pp 376–387

Zhang J, Sun H, Wan J, Yi Z (2009) Study on microstructure and mechanical property of interfacial transition zone between limestone aggregate and sialite paste. Constr Build Mater 23(11):3393–3397

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Yao, Y., Gong, J.K. & Cui, Z. Anti-corrosion performance and microstructure analysis on a marine concrete utilizing coal combustion byproducts and blast furnace slag. Clean Techn Environ Policy 16, 545–554 (2014). https://doi.org/10.1007/s10098-013-0654-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10098-013-0654-y