Abstract

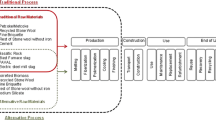

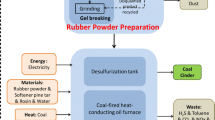

Life cycle assessment is used to determine the most environmentally beneficial alternatives for reuse of scrap tires, based on the concept of industrial ecology. Unutilized scrap tires can be a major source of pollution, and in the past decade Federal and state governments in the United States have encouraged the recycling and reuse of scrap tires in a number of applications, ranging from energy recovery to civil engineering materials to utilization of ground rubber in manufacturing. Life cycle inventory data are collected from primary industry sources as well as published literature, and life cycle impact analysis is performed using the TRACI tool. The results indicate that beneficial reuse of scrap tires, particularly in cement plants and artificial turf, provides reductions in greenhouse gas (GHG) emissions, air toxics, and water consumption. For example, every metric ton of tire-derived fuel substituted for coal in cement kilns avoids an estimated 543 kg (CO2 equivalent) of direct and indirect GHG emissions. Taking into account the deductible CO2 from natural rubber, the avoided GHG emissions would be 613 CO2 kg eq. per metric ton. The use of scrap tires for fuel in cement plants provides more reductions in most environmental impact categories compared to other scrap tire applications, excluding application in artificial turf. Although the use of ground rubber for artificial turf offers the greatest environmental emission reductions, it has limited potential for large-scale utilization due to the saturated market for artificial turf. Therefore, the use of fuel derived from scrap tires in cement production appears to be an attractive option in view of its large market capacity and significant potential for environmental impact reductions.

Similar content being viewed by others

References

Bare JC, Norris GA, Pennington DW, McKone T (2002) TRACI: the tool for the reduction and assessment of chemical and other environmental impacts. J Indus Ecol 6(3–4):49–78

Blumenthal MH (2007) Beneficial use of tire shreds in civil engineering applications. PowerPoint Presentation, Arkansas Department of Roads

Boesch ME (2008) Environmental decision support tool to optimize waste co-processing in the cement industry (LCA4AFR). ETH Zuerich, Switzerland. https://www.ifuethzch/ESD/research/TEDST/index_EN. Accessed November 2009

Chertow MR (2007) Uncovering industrial symbiosis. J Indus Ecol 11(1):11–30

Claudio L (2008) Synthetic turf: health debate takes root. Environ Health Perspec 116(3):A116–A122

Corti A, Lombardi L (2004) End life tyres: alternative final disposal processes compared by LCA. Energy 29:2089–2108

Fiksel J (2002) Sustainable Development through Industrial Ecology. In: Lankey RL, Anastas PT (eds) Advancing sustainability through green chemistry and engineering. American Chemical Society, Washington, DC

Grimes BH, Steinbeck S, Amoozegar A (2003) Analysis of tire chips as a substitute for stone aggregate in nitrification trenches of onsite septic systems: status and notes on the comparative macrobiology of tire chip versus stone aggregate trenches. Small Flows Q 4(4):8–23

Heijungs R, Guinee JB (2007) Allocation and ‘What-if’ scenarios in life cycle assessment of waste management systems. Waste Manage 27:997–1005

Humphrey DN, Swett M (2006) Literature review of the water quality effects of tire derived aggregate and rubber modified asphalt pavement. Department of Civil and Environmental Engineering, University of Maine, Orono, Maine, 54 pp. http://www.epagov/epawaste/conserve/materials/tires/tdastudypdf. Accessed November 2008

ICF Consulting (2006) Life-cycle greenhouse gas emission factors for scrap tires. http://www.epa.gov/climatechange/wycd/waste/downloads/ScrapTires5-9-06.pdf. Accessed June 2009

Office of Environmental Health Hazard Assessment (OEHHA) (2007) Evaluation of health effects of recycled waste tires in playground and track products. Technical report for Integrated Waste Management Board, Sacramento, CA, Publication #622-06-013. http://www.ciwmbcagov/Publications/Tires/62206013pdf. Accessed January 2009

Ohio EPA (2007) What is a scrap tire? http://www.epastateohus/dsiwm/document/guidance/gd_642pdf. Accessed December 2008

Portland Cement Association (PCA) (2008) How Portland cement is made. http://www.cementorg/basics/howmadeasp. Accessed October 2008

Reisman JI (1997) Air emissions from scrap tire combustion. Technical Report prepared for USEPA. Office of Research and Development, Washington, DC

Rubber Manufacturers Association (RMA) (2006) Scrap tire markets in the United States. RMA, Washington, DC

Rubber Manufacturers Association (RMA) (2007) State legislation-Scrap tire disposal. https://www.rmaorg/publications/scrap_tires/indexcfm?PublicationID=11121. Accessed December 2008

Udo de Haes HA, Jolliet O, Finnveden G, Hauschild M, Krewitt W, Mueller-Wenk R (1999a) Best available practice regarding impact categories and category indicators in life cycle impacts assessment, Part 1. Int J LCA 4(2):66–74

Udo de Haes HA, Jolliet O, Finnveden G, Hauschild M, Krewitt W, Mueller-Wenk R (1999b) Best available practice regarding impact categories and category indicators in life cycle impacts assessment, Part 2. Int J LCA 4(3):167–174

US Environmental Protection Agency (EPA) (2008) Scrap Tires. http://www.epagov/epawaste/conserve/materials/tires/indexhtm. Accessed January 2009

World Business Council for Sustainable Development (WBCSD) (2005) Guidelines for the selection and use of fuels and raw materials in the cement manufacturing process, Geneva

Acknowledgments

This LCA study was commissioned by Holcim, a worldwide cement company that has embraced the practice of industrial ecology including the use of tire-derived fuel. Holcim provided primary data for characterization of cement production processes. At Holcim’s request, The Ohio State University has conducted the study in an independent and unbiased manner.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Fiksel, J., Bakshi, B.R., Baral, A. et al. Comparative life cycle assessment of beneficial applications for scrap tires. Clean Techn Environ Policy 13, 19–35 (2011). https://doi.org/10.1007/s10098-010-0289-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10098-010-0289-1