Abstract

Sugi (Cryptomeria japonica D. Don) lumber is known to have a large variability in final moisture content (MCf) and is difficult to dry. This study investigated the variability in MCf of sugi in relation to wood properties. The wood property variables included initial moisture content (MCi), basic density (BD), annual ring orientation (ARO), annual ring width (ARW), heartwood ratio (HR) and CIE L * color (L *). Sugi samples were cut from flat-sawn lumbers and air-dried; a principal component regression (PCR) model for predicting MCf was developed with the wood property variables. The wood properties that contributed to the prediction of MCf were evaluated by PCR analysis. Significant positive regression coefficients of the PCR model were observed in the MCi, BD, ARO and HR, whereas negative ones in the L *. There were no significant regression coefficients in the ARW. These results suggest that the MCi, BD, ARO and HR had a positive influence, the L * had a negative influence, and the ARW had little influence on the MCf of air-dried sugi wood. This finding is in line with the general view on the drying characteristics in relation to these wood properties.

Similar content being viewed by others

Introduction

In the process of drying lumber, the variability in final moisture content (MCf) between lumbers is one of the major concerns. Factors that influence the MCf of lumber have been studied extensively and it has been shown that MCf depends on many wood properties, such as initial MC (MCi) [1–3], basic density (BD) [2–6], annual ring orientation (ARO) [3, 6–8], heartwood ratio (HR) [1, 3, 8–10], as well as dimensions of lumber and species. The ARO refers to the growth ring orientation relative to the main drying surfaces as seen from the lumber’s end. However, the past studies generally have employed simple linear correlation analysis between the pair of MCf and the above wood properties, and rarely have accounted for their interrelations. Therefore, the correlations obtained in the past studies were significant but weak. An exception is the study by Berberović [3], who used multiple regression analysis to investigate the impact of many wood properties on the drying rate of Tsuga heterophylla lumber. It was found that MCi, BD, HR and ARO influenced drying rate for the drying at 80 °C and only MCi for the drying at 115 °C. However, the wood property variables in the multiple regressions are intercorrelated with each other, and this makes it impossible to assess the relative importance of individual variables from the equation. Hence, more sophisticated multivariate data analysis is required to evaluate the wood properties that influence the MCf and the extent to which it is influential.

Sugi (Cryptomeria japonica D. Don) is one of the dominant species in Japan, but is very difficult to dry. Sugi lumber is well known to have a large variability in MCf, probably due to the large variability in MCi. The MCi of sugi heartwood is excessively variable, with black-colored heartwood having much higher MCi than normal red-colored heartwood [11, 12]. The increase in MCi relates to the blackening of heartwood [13], and the MCi was found to be strongly negatively correlated with brightness (CIE L * color) [12], which is considered to represent the difference in heartwood color. Furthermore, Sugimori et al. [1] demonstrated that the heartwood color of green sugi lumber was a good indicator of MCf after kiln-drying. Thus, the L * seems to be a potential important factor to determine MCf of sugi lumber in addition to MCi, BD, ARO and HR.

Purpose of this study was to investigate the wood properties that influence the MCf of sugi wood and the extent to which it is influential. Drying tests were conducted with small samples of sugi that had varying MCi, BD, ARO, HR and L *. Although few studies have reported that annual ring width (ARW) has an influence on MCf, ARW was also included as a potential factor, because ARW is an annual ring characteristic as well as ARO. A principal component regression (PCR) model for predicting MCf was developed, and the wood properties that contributed to the prediction of MCf were evaluated by PCR analysis.

Materials and methods

Sample preparation

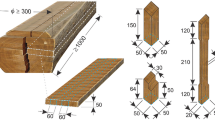

Ten green flat-sawn lumbers of sugi (Cryptomeria japonica D. Don), 70 cm long, 12 cm wide, and 4 cm thick, were obtained from different trees in Ehime Prefecture, Japan. A clear section was taken from each lumber and was cut into a thickness of 3 cm with a band saw. The section was further cut into eight similar blocks in size (Fig. 1a). One block was lost during the cut, and a total of 79 blocks were prepared. The block was split into two matched samples (Fig. 1b). One sample with a dimension of 30 × 10 × 10 mm was subjected to measurement of wood properties, and the other one with a dimension of 30 × 20 × 10 mm was subjected to drying test (Fig. 1c).

Measurement of wood properties

The ARO, ARW, HR and L * of the samples were measured from their cross-sectional images, while the BD was measured gravimetrically. The image of the samples was taken using a digital scanner (GT-X900, Seiko Epson Co., Tokyo, Japan) and analyzed by means of ImageJ software [14], so that ARO, ARW, HR and L * in the cross section were obtained for each sample. The volume of the samples was measured with a digital caliper. The samples were oven-dried, and the oven-dry weight and the BD of the samples were determined.

Drying test

Prior to the drying test, the surfaces of the sample, except the two surfaces normal to the thickness direction of original lumber, were sealed with silicone and aluminum foil (Fig. 1b). The weight of the sealing was calculated by subtracting the weight before sealing from the one after sealing. Thereafter, the samples were placed and air-dried for 28 days in a conditioning room at a temperature of 20 ± 1 °C and a relative humidity of 44 ± 2 % RH. The weight of each sample was measured once in a day. After the drying, the samples were oven-dried until the constant weight was attained and their MCi and moisture content during drying were determined by oven-dry method. The moisture content of the samples took 8 days on average to reach 15 %, which is often regarded as a desired MCf of dried lumber for general construction use. Therefore, the MCf of the samples was defined as the moisture content after a drying period of 8 days.

Multivariate data analysis

Principal component regression (PCR) analysis [15] was used to develop a regression model for predicting MCf, and to measure how each wood property affects the model. The PCR is a two-step procedure which computes to find a few linear combinations [called principal components (PCs)] of the several predictors (X variables), then fits a multiple linear regression using only these PCs. The PCs are created such that the first PC accounts for the maximum variation in the X variables, the second PC accounts for as much of the remaining variance as possible, and so on. The PCs are not intercorrelated with each other, and irrelevant and unstable information is discarded and only the most relevant part of the variation is used to correlate with a response variable (Y variable).

The PCR was performed using Unscrambler X version 10.2 (Camo Software Inc., Woodbridge, NJ, USA). The Y variable included MCf, while the X variables included MCi, BD, ARO, ARW, HR and L *. All the variables were mean centered and scaled to unit variance so that the variables with different scales have the same chance to influence the prediction of MCf. A PCR model for predicting MCf was developed with the data set. The optimal number of PCs was determined by full cross-validation (also called leave-one-out cross-validation), which removes one sample from the data set and constructs the model without these data. In the full cross-validation, the response of the residual variance with added PCs was observed. The number of PCs which corresponded to the first minimal residual variance was adopted as optimal.

The predictive ability of the model was assessed by two ways. First, the MCf for each sample was predicted using the PCR model and was compared with the measured one. Second, the PCR model in the full cross-validation was used to predict the MCf of the removed sample, and the predicted MCf was compared with the measured one. The former and the latter are called here “calibration” and “cross-validation”, respectively.

Results and discussion

Variability in wood properties and MCf

The wood properties and the MCf of the samples were listed in Table 1. A large variation was obtained in the individual wood properties and the MCf. The MCf variation and its correlation with these properties were analyzed using Pearson’s matrix correlation (shown in Table 2), by which the variability in MCf of Gmelina arborea in relation to distance from the pith and anatomical elements was evaluated [3]. Note that in this study the absolute value of the correlation coefficient (r) higher than 0.7 is regarded as strong, the value between 0.5 to 0.7 as moderate, and the value below 0.5 as weak. The MCf showed a statistical positive correlation with MCi but the correlation (r = 0.33) was weak (Fig. 2), indicating that it was difficult to predict the MCf based on the MCi. A weak positive correlation between MCf and HR showed that the MCf increased with increasing the HR. This result is in agreement with the slower drying in heartwood than sapwood due to lower heartwood permeability than sapwood [16]. As is depicted in Fig. 3, the L * showed a moderate negative correlation with the MCf (r = −0.60), meaning that the MCf decreased with increasing the L *. Sapwood, which dries faster than heartwood [16], is considered to have higher L * than heartwood, because HR was negatively correlated with L *, as shown in Table 2. In addition, it has been reported that sugi heartwood with higher L * has lower MCi. [12]. Hence, the samples with higher L * might probably result in the lower MCf.

MCf has been shown to depend on BD [2–6] and ARO [3, 6–8]. In the matrix correlation, however, the BD and the ARO showed no significant correlation with the MCf. This is because the simple linear correlation analysis did not account for the interrelation among wood properties, some of which were found in the significant correlations, as shown in Table 2.

Interpretation of PCR model

The optimal number of PC was 4, so the PCR model consisted of first 4 PCs. Y-explained variance and X-explained variance were used to interpret how much of Y variable and X variable, respectively, are described by the PCR model. The Y-explained variance shows the contribution of each factor to explain the deviation of Y variable (MCf), while the X-explained variance to explain the deviation of X variables (MCi, BD, ARO, ARW, HR and L *). As listed in Table 3, the Y-explained variance of PC1 and PC4 were 20.2 and 30.6 %, respectively, and those of the other PCs were close to 0 %. Thus, the PC1 and PC4 significantly contributed to the prediction of MCf in the PCR model. It is unexpected that the highest Y-explained variance among 4 PCs was observed in the PC4, which had only 13.1 % of the X-explained variance.

X loading is directly related to how well X variables are taken into account by factors in the model. Figure 4 shows the X loadings of PC1 and PC4 for each variable. The PC1 explaining 38.7 % of X variances was mainly related to ARO, ARW, HR and L *, rather than to MCi and BD. The PC4 with the highest Y-explained variance was mainly related to ARO and L *. This indicates that the ARO and L * largely contributed to the prediction of MCf.

Important variables contributed to the prediction of MCf

The weighted regression coefficients in the PCR model were useful to determine important wood properties correlated to the prediction of MCf. The Marten’s uncertainty test [17] was used to find the wood properties with significant regression coefficients. The regression coefficients of all wood properties except ARW were significantly different from zero according to the Martens’ uncertainty test (Fig. 5). No significant regression coefficients in the ARW shows that the ARW had little impact on the MCf. Significant positive regression coefficients were observed in the MCi, BD, ARO and HR, while negative ones were observed in the L *. These results demonstrate that many wood properties had an influence on MCf; that is, the MCi, BD, ARO and HR had a positive influence on the MCf, while the L * had a negative influence on the MCf.

It is apparent that the regression coefficients of L * and ARO were obviously higher than that of MCi. Thus, the L * and ARO contributed more to the prediction of MCf than did the MCi. MCi is often used as an indicator of MCf, but is very difficult to measure accurately without oven-drying. Meanwhile, L * and ARO can be measured easily from a lumber’s end. Therefore, it is expected that the L * and ARO have a potential to be used as an indicator of MCf, instead of MCi.

The positive regression coefficients in the BD and ARO are in consistent with the findings that MCf increases with increasing BD [2–6] and ARO [3, 6–8]. In general, wood with lower BD dries faster than that with higher BD, because the structure of wood with lower BD contains thinner cell walls and more openings per unit volume, which contributes to an increase in the diffusion of bound water and free water, respectively. Radial diffusion, perpendicular to the growth rings, is somewhat faster than tangential diffusion, parallel to the rings [18]. This explains why the samples with lower ARO resulted in the higher drying rate and consequently the lower MCf. Pang [19] gave a reasonable explanation why the radial diffusion of free water is faster than the tangential diffusion in Pinus radiata. During drying, the moisture within the wood material can either flow along the radial ray cells or through bordered pits which are on the radial-longitudinal face [20]. However with drying, the bordered pits aspirate but the ray cells are cleared. This increases the gas permeability and the moisture flow in radial direction [21, 22].

In the PCR model, the BD and ARO were judged as important variables for MCf, although the matrix correlation, as shown in Table 2 showed no significant correlation between MCf and these wood properties. Therefore, it is reasonable to suggest that the PCR model could to some extent account for the interrelation between MCf and the wood properties that was ignored by the traditional simple linear regression.

The above findings are in line with the general view on the drying characteristics in relation to these wood properties. It should be noted, however, that the PCR model was useful within the limited conditions of this study in which the samples were cut from the flat-sawn lumbers and did not cover the entire range of wood properties, for example, no sample with ARO over 65º was included in the PCR model. Therefore, samples from quarter-sawn as well as flat-sawn lumbers should be examined to confirm that the findings obtained from the PCR analysis can be generalized to the entire range of wood properties.

Prediction of MCf

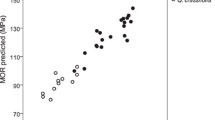

Figure 6 shows the plots of measured MCf versus predicted MCf. For both the calibration and the cross-validation, the predicted MCf was correlated with the measured one strongly and moderately, respectively. The predictive ability in the cross-validation was slightly poorer than the one in the calibration. The PCR model gave higher correlation coefficient than the matrix correlation among all pairs, as shown in Table 2. Thus, The PCR model could predict MCf of the samples more accurately than the single linear correlation analysis. However, the remaining 26–33 % of the variance in MCf was not explained by the PCR model. This result implies that the PCR analysis with these wood properties is insufficient to fully describe the interrelation between MCf and wood properties. In our next paper, we will present a nonlinear analysis for more comprehensive description of the interrelation, as an alternative to the PCR analysis based on a linear regression.

Conclusions

Drying tests were conducted with small sugi samples with varying MCi, BD, ARO, ARW, HR and L *. A PCR model for predicting MCf was developed and the wood properties that had an impact on the model were evaluated. The PCR analysis demonstrated that many wood properties had an influence on MCf. The MCi, BD, ARO and HR had a positive impact on the MCf, the L * had a negative impact on the MCf, and the ARW had little impact on MCf. On the other hand, the traditional simple linear regression could not find significant correlations between MCf and BD and between MCf and ARO. These results indicate that the PCR is more useful for the comprehensive evaluation of the variability in MCf in relation to wood properties than the traditional simple linear regression. This study adds value to existing research by presenting statistical evidence on sources of variation that may influence the MCf of sugi lumber.

References

Sugimori M, Hayashi K, Takechi M (2006) Sorting sugi lumber by criteria determined with cluster analysis to improve drying. For Prod J 56:25–29

Muñoz F, Moya R (2008) Moisture content variability in kiln-dried Gmelina arborea wood: effect of radial position and anatomical features. J Wood Sci 54:318–322

Berberović A (2010) The impact of wood variability on the drying rate at different moisture content levels. Ph.D. dissertation, Oregon State University, USA

Zhang Y, Oliveira L, Avramidis S (1996) Drying characteristics of hem-fir squares as affected by species and basic density presorting. For Prod J 46:44–50

Luostarinen K, Heikkonen S, Korri J (2010) Effects of basic density, annual growth and drying schedule on selected quality factors of dried Siberian larch (Larix sibirica) timber. Wood Mater Sci Eng 1:24–33

Luostarinen K, Heikkonen S (2012) Effect of radial origin on final moisture content and gradient, casehardening, cracking and deformations of dried Siberian larch (Larix sibirica) timber. Eur J Wood Prod 70:69–77

Hao B, Avramidis S (2004) Annual ring orientation effect and slope of grain in hemlock timber drying. For Prod J 54:41–49

Moya R, Tovar DA, Tenorio C, Bond B (2011) Moisture content variation in kiln-dried lumber from plantations of Vochysia guatemalensis. Wood Fiber Sci 43:121–129

Holmes S, Arganbright DG (1984) Green sorting incense-cedar for increased air-drying yard throughput. For Prod J 34:57–63

Gu H, Young TM, Moschler WW, Bond BH (2004) Potential sources of variation that influence the final moisture content of kiln-dried hardwood lumber. For Prod J 54:65–70

Fujiwara S, Iwagami S (1989) Relationship between green moisture content and heartwood color of sugi and hinoki (in Japanese). Bull Kochi Univ For 16:19–23

Kawazumi K, Oda K, Tsutsumi J (1991) Heartwood properties of sugi (Cryptomeria japonica): moisture content of green wood, hot water extractives and lightness (in Japanese). Bull Kyushu Univ For 64:29–39

Kubo T, Ataka S (1998) Blackening of sugi (Cryptomeria japonica D. Don) heartwood in relation to metal content and moisture content. J Wood Sci 44:137–141

Abramoff MD, Magalhaes PJ, Ram SJ (2004) Image processing with ImageJ. Biophoton Int 11:36–42

Esbensen KH (2002) Multivariate data analysis in practice: An introduction to multivariate data analysis and experimental design, 5th edn. CAMO Process AS, Oslo, pp 128–136

Fujii T, Suzuki Y, Kuroda N (1997) Bordered pit aspiration in the wood of Cryptomeria japonica in relation to air permeability. IAWA J 18:69–76

Westad F, Martens H (2000) Variable selection in near infrared spectroscopy based on significance testing in partial least squares regression. J Near Infrared Spec 8:117–124

Simpson WT (1991) Dry kiln operator’s handbook. USDA, FPL No. 188, Madison, Wisconsin, pp9–10

Pang S (2002) Effects of sawing pattern on lumber drying: model simulation and experimental investigation. Dry Technol 20:1769–1787

Pang S (1994) High-temperature drying of Pinus radiata boards in a batch kiln. Ph.D. dissertation, University of Canterbury, Christchurch, New Zealand

Booker RE (1991) Changes in transverse wood permeability during the drying of Dacrydium cupressinum and Pinus radiata. New Zeal J For Sci 20:231–244

Booker RE, Evans JM (1994) The effect of drying schedule on the radial permeability of Pinus radiata D. Don. Eur J Wood Prod 52:150–156

Acknowledgments

The authors would like to thank Mr. S. Shimozawa, a technician in the wood processing department of Forestry and Forest Products Research Institute, for his assistance in the experiments.

Author information

Authors and Affiliations

Corresponding author

About this article

Cite this article

Watanabe, K., Kobayashi, I. & Kuroda, N. Investigation of wood properties that influence the final moisture content of air-dried sugi (Cryptomeria japonica) using principal component regression analysis. J Wood Sci 58, 487–492 (2012). https://doi.org/10.1007/s10086-012-1283-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10086-012-1283-5