Abstract

To investigate the factors affecting the surface-check variation in boxed-heart square timber of sugi (Cryptomeria japonica), surface checks formed by the conventional kiln drying were compared for two stem heights of five cultivars with different wood properties. The total length and average length of the surface checks were greater at the upper part of the stems for all the cultivars. This might be caused by more sapwood at the upper part of the stem, and large drying stresses between the outer sapwood and the inner heartwood. The cultivars, in which tangential shrinkage was large owing to small microfibril angle, formed longer surface checks and smaller bow. There was a positive relationship between surface-check length and tangential shrinkage. The heartwood percentage and tangential shrinkage were thought to be important factors affecting the surface-check variation in sugi boxed-heart square timber.

Similar content being viewed by others

Introduction

Sugi (Cryptomeria japonica D. Don) is a major plantation species in Japan and its boxed-heart timber is mainly used as posts or beams for house construction. Recently, to shorten the construction period and prevent dimensional changes from significant shrinkage after completion, there has been a greater demand for dried timber. Fundamental research on the drying of sugi boxed-heart timber has been carried out with the aim of developing efficient drying methods, especially for fast drying without surface check [1, 2]. However, there are few reports on the surface-check variation on timber.

When timber exhibits large variation in the wood properties related to drying speed and surface check, the drying schedule must be adjusted for the timber that takes longer to dry and is susceptible to surface check. If the timber is classified according to the wood properties and is dried under the appropriate drying schedule, the cost and energy required for kiln drying are expected to be reduced.

For boxed-heart timber, drying check is inevitable for two reasons related to drying stress: moisture gradient and shrinkage anisotropy [3]. One reason is that in the first stage of the drying of large-dimension timber, only the outer part dries and shrinks, which causes tension stress at the dried outer part and compression stress in the wet inner part. The moisture gradient and the drying stress become larger if the timber contains the sapwood at the outer part and the heartwood at the inner one, because the sapwood dries faster than the heartwood. The other reason is that the tangential shrinkage is much larger than the radial shrinkage, while the tangential strength is lower than the radial strength. Both the moisture gradient and transverse shrinkage of sugi boxed-heart square timber exhibit large variation. The moisture gradient mainly depends on the heartwood percentage, and the difference between the moisture content of heartwood and that of sapwood. The heartwood percentage varies substantially with tree growth. The moisture content of heartwood varies largely among cultivars and along the stem [4, 5]. The shrinkage, which is affected by microfibril angle (MFA), density, and tree ring parameters, also exhibits variation among cultivars and within the stem especially at the core of stem [6, 7].

In this study, the surface-check variation of sugi boxed-heart square timber was evaluated using conventional kiln-dried timber taken at different heights along the stem for five cultivars with different wood properties [6–8]. The relationships between surface checks and moisture gradient, shrinkage, and bow were investigated.

Materials and methods

Materials

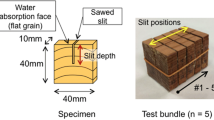

The five sugi cultivars applied for this experiment were: boka-sugi, aya-sugi, ryuunohige, yabukuguri, and kumotooshi (Table 1). The sample trees were used in our previous studies on shrinkage [6, 7] and bow [8]. The trees of each cultivar were taken from the same stands (boka-sugi: Takaoka, Toyama; aya-sugi and yabukururi: Kahoku, Kumamoto; ryuunohige and kumotooshi: Kikuchi, Kumamoto). Logs were taken at two heights above the ground (lower height, “timber 1”; upper height, “timber 4”) (Fig. 1) and sawn into boxed-heart square timber of cross-sectional dimensions 115–120 mm and length 1.8–2 m, including the pith at the centers of both ends. The sampling heights for timber 1 were 0.7–2.6 m for boka-sugi and ryuunohge, 0.6–2.4 m for aya-sugi, and 1.5–3.5 m for yabukuguri and kumotooshi. The sampling heights for timber 4 were 6.4–8.3 m for boka-sugi, 6.0–7.8 m for aya-sugi, 6.0–7.9 m for ryuunohige, and 6.1–8.1 m for yabukuguri and kumotooshi. Disks were cut from both ends of the logs to estimate wood properties.

Wood properties

The heartwood percentage (HWP) on the transverse faces of the timber was calculated from the heartwood radius and timber dimensions. Tangential and radial shrinkages from the green to oven-dry conditions (α Tii, α Rii) at 60 mm from the pith (suffix ii indicates the distance from the pith [8]) were measured using small clear samples of dimensions 30 (T) × 30 (R) × 5 (L) mm for boka-sugi, aya-sugi, and ryuunohige, and 20 (T) × 20 (R) × 5 (L) mm for yabukuguri and kumotooshi. Basic density (BD) was measured using small blocks cut at 20 mm intervals from the pith to the edge of the timber, and then averaged. The wood properties in two diametrically opposite directions were averaged for each disk, and the disks at both ends of the timber were averaged for each piece of timber. The modulus of elasticity of the green timber (MOEGT) was measured by using the tapping method [9]. The fundamental frequency of longitudinal vibration was obtained with a fast Fourier transform digital signal analyzer (Ryon SA-71). The MOEGT was calculated using Eq. 1

where L is the length, f is the fundamental frequency of longitudinal vibration, and ρ is the green density.

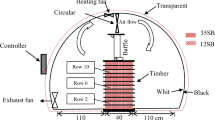

Kiln drying

The timber was kiln dried in four groups: (1) boka-sugi, (2) aya-sugi, (3) ryuunohige, and (4) yabukuguri and kumotooshi (Table 1). Timber from different heights and/or cultivars were arranged alternately in the layers of the stack in the kiln (SKIF10LPT, Shinshiba) installed in the Forestry and Forest Products Research Institute. The drying schedule was: steaming (85°C dry bulb, 85°C wet bulb, 8 h), drying (85–95°C dry bulb, 81–82°C wet bulb, 136 h), and conditioning (95°C dry bulb, 91°C wet bulb, 24 h).

Measuring surface checks and bow

After kiln drying, the length and number of surface checks on the four lateral faces were measured, summed, and divided by the length at the point of green condition as the total length of surface checks and the number of surface checks. The average length of surface checks was obtained as total length divided by the number. Surface checks shorter than 100 mm and longer than 100 mm were counted separately. The surface checks extending from the end of the timber (end-surface check) and the surface checks not extending from the end of the timber (center-surface check) were also separated. The bow distortion of the timber was calculated as the sum of the maximum deflections of all planes divided by the length at the point of green condition [8]. The moisture contents of the green timber (MCGT) and dried timber (MCDT) were obtained as a fraction of the oven-dry wood weight.

Statistical analysis

The differences in wood properties and surface check between samples from different source heights were examined using a paired t test for each cultivar. The differences among the samples of yabukuguri and kumotooshi (Y1, Y4, K1, K4), which were kiln dried together, were examined using the one-way analysis of variance (ANOVA) and the Tukey–Kramer honestly significant difference (HSD) test. The relationships between the surface check, wood properties, and bow distortion were examined by correlation analysis.

Results

Wood properties

Timber 1 exhibited greater HWP than timber 4 (Table 1). Among the cultivars, the HWP of timber 4 was greater for aya-sugi (A) and yabukuguri (Y), and smaller for boka-sugi (B).

The MCGT was high in timber 4 of boka-sugi (B), since it contained a large percentage of sapwood. For ryuunohige and kumotooshi (R, K), MCGT was higher in timber 1 than in timber 4, since the moisture contents of their heartwood were high (R1 94%, K1 152%) as shown in our previous study [8]. The MCDT was higher in timber 1 than in timber 4 for boka-sugi, ryuunohige, and kumotooshi (B, R, K), since timber 1 contained a larger percentage of heartwood. On the other hand, the MCDT and HWP at the two source heights were not significantly different for aya-sugi and yabukuguri (A, Y).

Tangential shrinkage (α Tii) and radial shrinkage (α Rii) were larger in timber 4 than in timber 1, whereas the tangential/radial shrinkage ratio (α Tii/α Rii) was larger in timber 1 for most cultivars (Table 2). Comparison of the cultivars showed that: α Tii was small for boka-sugi (B) and large for kumotooshi (K), α Rii was small for boka-sugi, aya-sugi and yabukuguri (B, A, Y), and large for ryuunohige and kumotooshi (R, K). On the other hand, α Tii/α Rii was large for yabukuguri (Y) and small for boka-sugi and ryuunohige (B, R).

The BD was higher in timber 4 than in timber 1 for aya-sugi, ryuunohige, and yabukuguri (A, R, Y), whereas timber 1 and timber 4 exhibited similar BD for boka-sugi and kumotooshi (B, K). Among the cultivars, BD of aya-sugi (A) was the highest, and that of boka-sugi (B) was the lowest.

The MOEGT was higher in timber 4 than in timber 1 for all the cultivars, although the difference was not significant for kumotooshi (K). Among the cultivars, the MOEGT was high for ryuunohige and kumotooshi (R, K) and low for boka-sugi and yabukuguri (B, Y). The differences between the source heights and among cultivars might be influenced by MFA variation within stem and among cultivars as shown in our previous study [6].

Surface check

The surface check of the timber at the two source heights varied for each cultivar (Fig. 2). Some boka-sugi and ryuunohige timber (B1, 43%; R1, 70%; R4, 20%) did not have surface check, while a few kumotooshi boxed-heart squares (K4) had surface checks for the full length of each timber from end to end. When the surface check was compared at the two source heights for each cultivar, the total length and average length of the surface checks were longer, and the number of surface checks was greater in timber 4 than in timber 1 (Fig. 2). The maximum length of surface check was longer in timber 4 for most cultivars (Table 3). A similar trend was observed when the end-surface checks shorter than 100 mm were excluded (Fig. 2). Among the cultivars, yabukuguri and kumotooshi (Y, K) exhibited more numbers of short-end checks than the other cultivars.

Mean of the total length, number, and average length of surface checks for each sample group. Asterisks show significant differences between timber 1 and timber 4 (from different source heights) within cultivars using a paired t test (***P < 0.001, **P < 0.01, *P < 0.05). End-surface checks and center-surface checks shorter than 100 mm and longer than 100 mm were separated for the total length and number of surface checks

The two cultivars, yabukuguri (Y) and kumotooshi (K), kiln dried together were compared (Fig. 2). The number of surface checks was larger for yabukuguri, and the average length of the surface checks was longer for kumotooshi. Yabukuguri exhibited more short-end-surface checks than kumotooshi. When end-surface check shorter than 100 mm were excluded, the total length of surface checks was shorter for yabukuguri than kumotooshi both in timber 1 (Y1, 202 mm/m; K1, 465 mm/m) (P = 0.10) and timber 4 (Y4, 486 mm/m; K4, 1036 mm/m) (P < 0.01), and the average length of surface checks was shorter for yabukuguri than kumotooshi in timber 1 (Y1, 128 mm; K1, 203 mm) (P = 0.12) and timber 4 (Y4, 206 mm; K4, 782 mm) (P < 0.01). The number of surface checks was identical for the two cultivars both in timber 1 (Y1, 1.7 count/m; K1, 2.1 count/m) (P = 0.48) and timber 4 (Y4, 2.3 count/m; K4, 1.8 count/m) (P = 0.18).

Relationships between surface check, wood properties, and bow

The total length of all surface checks was positively correlated with α Tii (P < 0.001), the MOEGT (P < 0.01), and the specific MOEGT (P < 0.01). On the other hand, the correlations were not significant for α Rii (r = 0.17, P = 0.05), α Tii/α Rii (r = 0.13, P = 0.14), and BD (r = 0.15, P = 0.10). When the end-surface checks shorter than 100 mm were excluded, the total length of the surface checks was positively correlated with α Tii, α Rii, the MOEGT, and the specific MOEGT (P < 0.001) (Fig. 3). On the other hand, the correlations were not significant for α Tii/α Rii (r = −0.16, P = 0.06) and BD (r = 0.15, P = 0.08). The total length of surface checks was negatively correlated with bow, both when including (P < 0.01) and excluding (P < 0.001) the end-surface checks shorter than 100 mm (Fig. 4).

Relationships between total length of surface checks and wood properties. End-surface checks shorter than 100 mm were excluded. α T ii tangential shrinkage, α R ii radial shrinkage, α T ii/α R ii tangential/radial shrinkage ratio, BD basic density, MOE GT the modulus of elasticity of green timber. ***P < 0.001. ◆ B1, ◊ B4, ▲ A1, △ A4, ▼ R1, ▽ R4, ● Y1, ○ Y4, ■ K1, □ K4

Discussion

Surface-check difference between source heights

The total length and the average length of the surface checks were longer at the upper part of the stem than the lower part (Fig. 2; Table 3). Katagiri et al. [10] also reported that the total length of surface checks was longer at the upper part of the stem than the lower part for two drying schedules. The difference between the source heights is most likely caused by the difference of HWP. As described in the introduction, when the drying proceeds from the outer part, drying stress occurs between the outer part, where shrinking has started (tension stress), and the inner part where shrinking has not occurred (compression stress). The heartwood dries more slowly than the sapwood, because the heartwood substance infiltrates the cell walls and covers the aspirated pits and decreases the moisture movement. Therefore, the timber containing the sapwood at the outer part will exhibit larger moisture gradients and drying stresses across timber compared with the timber containing only heartwood. In this study, timber 1 of the cultivars was mostly occupied by the heartwood, except for boka-sugi, whereas timber 4 contained the sapwood at the outer part (Table 1). Therefore, timber 1 might have smaller moisture gradients across the timber and less drying stress compared with timber 4. The difference in surface check along the stem was smaller for aya-sugi and yabukuguri than the other cultivars (Fig. 2; Table 3), which can be attributed to the similar HWPs of timber 1 and 4. Timber with a high percentage of heartwood and the timber with a high moisture content of heartwood will exhibit different drying speeds and drying stress, even if their average moisture contents are the same. To minimize the variation in moisture content and surface check after drying, it is better to classify the green timber not only for the average moisture content, but also for the HWP and the heartwood moisture content.

The difference in surface check along the stem is likely to be influenced by tangential shrinkage too. Our previous study [7] showed that tangential shrinkage was smaller at the bottom of the stem than at the upper part because of larger MFA. For aya-sugi, although timber 4 exhibited high HWP as timber 1, its total length of surface checks was longer than that of timber 1 (Fig. 2; Table 3). It might be because timber 4 exhibited larger tangential shrinkage than timber 1 (Table 2). On the other hand, the tangential/radial shrinkage ratio was smaller in timber 4 than in timber 1 for most cultivars. This result suggests that the shrinkage difference between tangential and radial direction is the fundamental reason causing surface checks in the boxed-heart timber; however, its effect on the surface-check variation is unclear.

Surface-check difference among cultivars

Yamanouchi et al. [11] reported that the total widths of surface checks were different among the six sugi cultivars, but they did not discuss the factors affecting the differences. In this study, the total lengths of surface checks were different among cultivars (Fig. 2; Table 3). The total length of the surface checks was positively correlated with the tangential shrinkage when all surface checks were included, and was correlated with tangential and radial shrinkage when the short-end checks were excluded. On the other hand, the total length of surface checks was not correlated with the tangential/radial shrinkage ratio or the BD. This result suggests that the surface-check variation among cultivars is affected by tangential shrinkage, which varies among cultivars due to the variation in MFA [7].

The reason that the short-end checks were excluded from the correlations for all the cultivars was that yabukuguri and kumotooshi exhibited more short-end checks than the other cultivars (Fig. 2). It was perhaps because of small differences in the kiln-drying conditions or by end checking of green logs before kiln drying. Since the two cultivars logs were kept for a longer time after harvesting than the other cultivars before being sawn and dried, more end checking might have resulted on the log ends.

Yabukuguri and kumotooshi, which were harvested, sawn, and kiln dried together, exhibited differences in surface check. Yabukuguri had a large number of short checks, while kumotooshi had a small number of long checks, including checks for the full length of each timber from end to end (Fig. 2). When the short-end-surface checks were excluded, the total length and average length of surface checks were shorter for yabukuguri than kumotooshi (Table 3). The difference is most likely caused by the tangential shrinkage being smaller for yabukuguri than kumotooshi (Table 2). Our previous study [7] showed the difference in shrinkage between the two cultivars was due to the MFA, which was larger for yabukuguri than kumotooshi, while their density was at the same level. The surface-check difference between the two cultivars is also likely to be caused by the heartwood moisture content. This was higher for kumotooshi, and its heartwood took longer time to dry, which would have caused larger moisture gradients between the heartwood and sapwood.

Relationships between surface check, MOE, and bow

Previous studies have shown that timber with higher MOE exhibited more surface checks and smaller bow than timber with lower MOE, even at the same density level [12–14]. This study also showed a positive relationship between the total length of surface checks and the MOEGT and specific MOEGT (Fig. 3), and a negative relationship between the total length of surface checks and bow (Fig. 4). It is most likely that the timber with small MFA exhibited high MOE, large tangential shrinkage, and small longitudinal shrinkage [6, 7], and that this caused more surface checks and less bow.

The relationship between surface check and MOEGT (r = 0.354) was not as strong as that between bow and MOEGT (r = 0.727) [8]. The total length of surface checks was short for ryuunohige, in spite of its high MOEGT. This might be caused by the bow being an elastic phenomenon, while the surface check is a destructive phenomenon and is affected not only by shrinkage, but also by other factors such as tensile creep, tensile strength, and the maximum tensile strain [15]. Furthermore, in this study, the moisture conditions, which have a strong effect on drying stress, varied among the cultivars because they were kiln dried separately.

The surface check occurs at the point where the drying stress exceeds the tensile strength. While the timber shrinks, the stress relaxation keeps the timber from splitting. Therefore, the tensile strength and the tensile creep in the tangential direction might affect the surface check [3]. Fujimoto et al. [16, 17] studied the effects of temperature or the moisture content on the shrinkage, drying stress, and creep compliance. Fujimoto et al. [17] showed that the creep compliance in radial compression creep tests decreased with distance from the pith, which suggested that not only the elasticity but also the viscosity might vary within the stem. If the difference in radius is related to the wood property characteristics of juvenile wood, the rheological properties in the tangential direction can be varied by the position within the stem or by cultivar.

A normal level of surface check will not decrease the strength properties [18, 19]. However, it is desirable to avoid surface checks comparable to a split liner, because it may reduce the shear modulus [20], the joint strength, and the dimensional stability [21, 22].

In this study, the length and number were used as indices of tendency to make surface check, but the check width is also an important index of tendency to evaluate the tendency and in market valuation. In this study, the checks were measured immediately after kiln drying to examine the difference under the same drying schedule, but the checks may change with time when the moisture contents are conditioned at a certain level.

This study used cultivar trees that were grown in the same stand and under the same management, because they exhibited small variation in wood properties. However, the timber taken from different stands would cause more variation in wood properties. Therefore, reducing the variation in wood properties of green timber to the same level for HWP, heartwood moisture content, and shrinkage might be effective in reducing the variation in drying checks in a kiln.

Conclusions

Sugi boxed-heart square timber at two source heights for five cultivars exhibited different surface checks. HWP and tangential shrinkage were the factors affecting the surface-check variation. The timber that included the sapwood at its outer part was susceptible to surface check due to the large drying stresses between the sapwood and heartwood. Timber having a large tangential shrinkage and a high MOE due to small MFA is likely to have longer surface checks and small bow.

References

Kuroda N (2005) Trends of wood drying research in Japan. Mokuzai Gakkaishi 51:10–12 (in Japanese)

Kuroda N (2007) Development of fundamental research on drying of boxed-heart square timber of Sugi (Cryptomeria japonica). Mokuzai Gakkaishi 53:243–253 (in Japanese with English summary)

Terazawa S (1994) Wood drying. Kaiseisha, Ootsu, pp 363–377, 566–576 (in Japanese)

Miwa Y (1991) Moisture content of green wood. In: Japan Wood Research Society (ed) Wood science and technology II 5. Sugi. The Japan Wood Research Society, Tokyo, pp 10–13 (in Japanese)

Nakada R, Fujisawa Y, Hirakawa Y, Yamashita K (1998) Longitudinal change of the green moisture content in the stem of Cryptomeria japonica D. Don. Mokuzai Gakkaishi 44:395–402 (in Japanese with English summary)

Yamashita K, Hirakawa Y, Nakatani H, Ikeda M (2009) Longitudinal shrinkage variations within trees of sugi (Cryptomeria japonica) cultivars. J Wood Sci 55:1–7

Yamashita K, Hirakawa Y, Nakatani H, Ikeda M (2009) Tangential and radial shrinkage variation within trees in sugi (Cryptomeria japonica) cultivars. J Wood Sci 55:161–168

Yamashita K, Hirakawa Y, Saito S, Nakatani H, Ikeda M (2011) Bow variation in kiln-dried boxed-heart square timber of sugi (Cryptomeria japonica) cultivars. J Wood Sci 57:363–370

Sobue N (1986) Measurement of Young’s modulus by the transient longitudinal vibration of wooden beams using a fast Fourier transformation spectrum analyzer. Mokuzai Gakkaishi 32:744–747

Katagiri Y, Urabe T, Murakami H (1999) Study on drying of regular squared timber of sugi lumber. Bull Kyushu Branch Jpn For Soc 52:137–138 (in Japanese)

Yamanouchi K, Katagiri Y, Mikada M, Wakamatsu S, Ikeda M, Tanihata S, Tachikiri T (1999) Drying properties of sugi cultivar. In: Abstracts of the 49th annual meeting of the Japan wood research society, p 123 (in Japanese)

Aratake S, Arima T, Sakoda T, Nakamura Y (1993) Effects of season crack on mechanical properties of sugi structural lumbers: modulus of rupture and modulus of elasticity in bending. Wood Ind 48:166–170 (in Japanese with English summary)

Andoh M, Ishiguri F, Nakamura M, Yoshizawa N (1999) Wood quality of sugi (Cryptomeria japonica D. Don) boxed heart square timbers treated by smoke-heating system with far-infrared radiation: on moisture content, surface check, dynamic Young’s modulus. J Soc Mater Sci Japan 48:229–234 (in Japanese with English summary)

Yamamoto M (1999) The effect of bend strength that was exerted by the kiln drying crack. Bull Hiroshima Prefect For Exp Stn 31:39–44 (in Japanese with English summary)

Sumi H (1991) Wood drying. In: Fushitani M, Okano T (eds) Wood processing. Buneidou, Tokyo, pp 64–77 (in Japanese)

Fujimoto N, Goto K, Mataki Y (1999) Fracture toughness of the surface layer of the boxed-heart square timber of sugi associated with drying check. J Soc Mater Sci Japan 48:223–228 (in Japanese with English summary)

Fujimoto N, Tachiwana K, Oouchi K, Mataki Y (2001) Tension creep of surface layer and compression creep of inner layer perpendicular to the grain in sugi boxed-heart square timber. J Soc Mater Sci Japan 50:914–919 (in Japanese with English summary)

Yoshida T, Itou Y, Hashizume T (2002) Relationship between checks and bending strength for air dried timber of sugi and karamatsu. Report of Nagano Prefectural Forestry Research Center, pp 80–81 (in Japanese)

Ikeda K (2005) The effect of drying-check and sawn slit on the strength performance of the structural lumber of sugi and hinoki. Bull Shizuoka Prefect For For Prod Res Inst 33:15–21 (in Japanese)

Sobue N, Matsuo K, Ikeda K (2000) Effect of depth of a sawn slit parallel to the fiber direction on shear modulus of commercial size square timbers. Mokuzai Gakkaishi 46:242–245 (in Japanese with English summary)

Fujimoto N, Fujimoto H, Kawabe J, Mataki Y (1994) Drying of boxed heart square timbers I. Changes of surface stress and cross-sectional shrinkage of dehumidifier kiln-dried timbers of sugi. Mokuzai Gakkaishi 40:758–765

Fujimoto N, Arita S, Mataki Y (1997) Changes of dimension and stress in surface layer of sugi dried boxed-heart square timbers with a split liner under cyclic environment. J Soc Mater Sci Japan 46:390–394

Acknowledgments

We express our gratitude to Dr. Trevor Jones, Dr. Naohiro Kuroda, and Dr. Mario Tonosaki for suggestions regarding the manuscript.

Author information

Authors and Affiliations

Corresponding author

About this article

Cite this article

Yamashita, K., Hirakawa, Y., Saito, S. et al. Surface-check variation in boxed-heart square timber of sugi (Cryptomeria japonica) cultivars dried by the conventional kiln drying. J Wood Sci 58, 259–266 (2012). https://doi.org/10.1007/s10086-011-1239-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10086-011-1239-1