Abstract

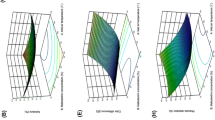

Optimization of spray drying conditions namely inlet air temperature (IAT) and maltodextrin (MD) concentration was utilized by response surface methodology for Japanese apricot (Prunus mume Sieb. et Zucc.) juice powder (JAJP) manufacture. Drying yield, moisture content, water solubility index (WSI), bulk density, color, pH, total phenol content (TPC), total flavonoid content (TFC), vitamin C content, and DPPH radical-scavenging activity of juice powder were measured. Moisture content, vitamin C content, color, DPPH radical-scavenging activity, pH, and bulk density were greatly influenced by IAT, but drying yield, WSI, TPC, and TFC were only significantly affected by MD concentration. The spray drying condition was optimum at 10% MD concentration and 165.8 °C IAT. The properties of juice powder were 37.50% drying yield, 4.81% moisture content, 134.25 mg/g vitamin C content, 27.52% DPPH radical-scavenging activity, 2.78 pH, 89.15% WSI, 232.856 μg GAE/100 g TPC, 404.66 μg CE/100 g TFC, and 0.49 bulk density.

Similar content being viewed by others

References

Anderson RA. Water absorption and solubility and amylograph characteristics of roll-cooked small grain products. Cereal Chemistry. 59: 265-269 (1982)

AOAC (Ed.), Official Methods of Analysis of AOAC International (20th ed.), AOAC international, Maryland, USA (2016)

Aragüez‐Fortes Y, Robaina‐Morales LM, Pino JA. Optimization of the spray‐drying parameters for developing guava powder. Journal of Food Process Engineering. 42: e13230 (2019)

Caliskan G, Dirim SN. The effects of the different drying conditions and the amounts of maltodextrin addition during spray drying of sumac extract. Food and Bioproducts Processing. 91: 539-548 (2013)

Chang LS, Tan YL, Pui LP. Production of spray-dried enzyme-liquefied papaya (Carica papaya L.) powder. Brazilian Journal of Food Technology. 23: e2019181 (2020)

Chegini GR, Ghobadian B. Effect of spray-drying conditions on physical properties of orange juice powder. Drying Technology. 23: 657-668 (2005)

Das PR, Eun JB. A comparative study of ultra-sonication and agitation extraction techniques on bioactive metabolites of green tea extract. Food Chemistry. 253: 22-29 (2018)

Fazaeli M, Emam-Djomeh Z, Kalbasi-Ashtari A, Omid M. Effect of process conditions and carrier concentration for improving drying yield and other quality attributes of spray dried black mulberry (Morus nigra) juice. International Journal of Food Engineering. 8: 1-20 (2012)

Finney J, Buffo R, Reineccius GA. Effects of type of atomization and processing temperatures on the physical properties and stability of spray‐dried flavors. Journal of Food Science. 67: 1108-1114 (2002)

Gabas AL, Telis VRN, Sobral PJDA, Telis-Romero J. Effect of maltodextrin and arabic gum in water vapor sorption thermodynamic properties of vacuum dried pineapple pulp powder. Journal of Food Engineering. 82: 246-252 (2007)

Hwang IG, Woo KS, Kim TM, Kim DJ, Yang MH, Jeong HS. Change of physicochemical characteristics of Korean pear (Pyrus pyrifolia Nakai) juice with heat treatment conditions. Korean Journal of Food Science and Technology. 38: 342-347. (2006)

Ioannou I, Hafsa I, Hamdi S, Charbonnel C, Ghoul M. Review of the effects of food processing and formulation on flavonol and anthocyanin behaviour. Journal of Food Engineering. 111: 208-217 (2012)

Kim JH, Kim JH, Eun JB. Optimization of spray drying process of Japanese apricot (Prunus mume Sieb. et Zucc.) juice powder using nondigestible maltodextrin by response surface methodology (RSM). Journal of Food Science and Technology. 1-11 (2021)

Lee KC, Yoon YS, Li FZ, Eun JB. Effects of inlet air temperature and concentration of carrier agents on physicochemical properties, sensory evaluation of spray-dried mandarin (Citrus unshiu) beverage powder. Applied Biological Chemistry. 60: 33-40 (2017).

Mishra P, Mishra S, Mahanta CL. Effect of maltodextrin concentration and inlet temperature during spray drying on physicochemical and antioxidant properties of amla (Emblica officinalis) juice powder. Food and Bioproducts Processing. 92: 252-258 (2014).

Nguyen DQ, Nguyen TH, Allaf K. Volumetric heat transfer coefficient in spray drying of soymilk powder. Drying Technology. 1-7 (2020)

Nishad J, Selvan CJ, Mir SA, Bosco SJD. Effect of spray drying on physical properties of sugarcane juice powder (Saccharum officinarum L.). Journal of food science and technology. 54: 687-697 (2017)

Patil V, Chauhan AK, Singh RP. Optimization of the spraydrying process for developing guava powder using response surface methodology. Powder Technology. 253: 230-236 (2014)

Peng Z, Li J, Guan Y, Zhao G. Effect of carriers on physicochemical properties, antioxidant activities and biological components of spray-dried purple sweet potato flours. LWT-Food Science and Technology. 51: 348-355 (2013)

Phisut N. Spray drying technique of fruit juice powder: some factors influencing the properties of product. International Food Research Journal. 19: 1297 (2012)

Pierucci APT, Andrade LR, Farina M, Pedrosa C, Rocha-Leão MHM. Comparison of α-tocopherol microparticles produced with different wall materials: pea protein a new interesting alternative. Journal of Microencapsulation. 24: 201-213 (2007)

Pires FCS, da Silva Pena R. Optimization of spray drying process parameters for tucupi powder using the response surface methodology. Journal of Food Science and Technology. 54: 3459-3472 (2017)

Poodi Y, Bimakr M., Ganjloo A., Zarringhalami S. Intensification of bioactive compounds extraction from Feijoa (Feijoa sellowiana Berg.) leaves using ultrasonic waves. Food and Bioproducts Processing. 108: 37-50 (2018)

Rajam R, Anandharamakrishnan C. Microencapsulation of Lactobacillus plantarum (MTCC 5422) with fructooligosaccharide as wallmaterial by spray drying. LWT—Food Science and Technology. 60: 773-780 (2015)

Robert M. Changes in carotenoids contents in pureed and cooked carrot and spinach during storage. The Korean Journal of Food Science and Technology. 19: 83-95 (2003)

Saikia S, Mahnot NK, Mahanta CL. Effect of spray drying of four fruit juices on physicochemical, phytochemical and antioxidant properties. Journal of Food Processing and Preservation. 39: 1656-1664 (2015)

Shin SC. Changes in components of Ume fruit during development and maturation. J Oriental Bot Res. Res. 8: 259-264 (1995)

Shishir MRI, Chen W. Trends of spray drying: A critical review on drying of fruit and vegetable juices. Trends in food science & technology. 65: 49-67 (2017)

Singh B, Hathan BS. Process optimization of spray drying of beetroot Juice. Journal of food science and technology. 54: 2241-2250 (2017)

Tamime AY. (Ed.). Dairy powders and concentrated products. John Wiley & Sons. (2009)

Tan SP, Tuyen CK, Parks SE, Stathopoulos CE, Roach PD. Effects of the spray drying temperatures on the physiochemical properties of an encapsulated bitter melon aqueous extract powder. Powder Technology. 281: 65-75 (2015)

Tonon RV, Brabet C, Hubinger MD. Influence of process conditions on the physicochemical properties of açai (Euterpe oleraceae Mart.) powder produced by spray drying. Journal of food engineering. 88: 411-418 (2008)

Tonon RV, Freitas SS, Hubinger MD. Spray drying of açai (Euterpe oleraceae Mart.) juice: effect of inlet air temperature and type of carrier agent. Journal of Food Processing and Preservation. 35: 691-700 (2011)

Wang Y, Lu Z, Lv F, Bie X. Study on microencapsulation of curcumin pigments by spray drying. European Food Research and Technology. 229: 391-396 (2009)

Whistler RL, BeMiller JN, Paschall EF. (Eds.). Starch: chemistry and technology. Academic Press. (2012)

Acknowledgements

This research did not receive funding.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Kim, JH., Kim, J.H. & Eun, JB. Optimization of spray drying process parameters for production of Japanese apricot (Prunus mume Sieb. et Zucc.) juice powder. Food Sci Biotechnol 30, 1075–1086 (2021). https://doi.org/10.1007/s10068-021-00950-8

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10068-021-00950-8