Abstract

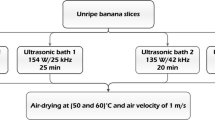

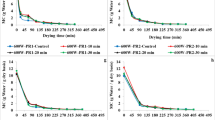

Ultrasound is a novel technology that can be applied as a pretreatment for the convective drying in order to reduce its undeniable shortcomings. The objectives of the present study are to ascertain the influence of sonication time (10, 20, and 30 min) and sonication power (100 and 300 W) on the performance of drying potato slices with regard to the drying kinetics and energy efficiency as well as the final product quality. The results showed that the application of ultrasound pretreatments significantly increased the drying rate of potato slices during the initial period of the drying process. Furthermore, ANOVA showed that the decrease in the sonication time and power gave rise to a significant reduction in drying time, specific energy consumption (SEC), and shear strength. In addition, compared to the control (pure convective drying), ultrasound pretreatments reduced the drying time, SEC, and the shear strength of dried potato slices.

Similar content being viewed by others

References

Abramov OV, Gedanken A, Koltypin Y, Perkas N, Perelshtein I, Joyce E, Mason TJ. Pilot scale sonochemical coating of nanoparticles onto textiles to produce biocidal fabrics. Surf. Coatings Technol. 204: 718–722 (2009)

Aghbashlo M, Kianmehr MH, Arabhosseini A. Modeling of thin-layer drying of potato slices in length of continuous band dryer. Energy Convers. Manag. 50: 1348–1355 (2009)

Bantle M, Eikevik TM. A study of the energy efficiency of convective drying systems assisted by ultrasound in the production of clipfish. J. Clean. Prod. 65: 217–223 (2014)

Başlar M, Kılıçlı M, Toker OS, Sağdıç O, Arici M. Ultrasonic vacuum drying technique as a novel process for shortening the drying period for beef and chicken meats. Innov. Food Sci. Emerg. Technol. 26: 182–190 (2014)

Chen Z-G, Guo X-Y, Wu T. A novel dehydration technique for carrot slices implementing ultrasound and vacuum drying methods. Ultrason. Sonochem. 30: 28–34 (2016)

de la Fuente-Blanco S, Riera-Franco de Sarabia E, Acosta-Aparicio VM, Blanco-Blanco A, Gallego-Juárez JA. Food drying process by power ultrasound. Ultrasonics 44: e523–e527 (2006)

Deng Y, Zhao Y. Effects of pulsed-vacuum and ultrasound on the osmodehydration kinetics and microstructure of apples (Fuji). J. Food Eng. 85: 84–93 (2008)

Fernandes FAN, Rodrigues S. Ultrasound as pre-treatment for drying of fruits: Dehydration of banana. J. Food Eng. 82: 261–267 (2007)

Fernandes FAN, Rodrigues S. Application of ultrasound and ultrasound-assisted osmotic dehydration in drying of fruits. Dry. Technol. 26: 1509–1516 (2008a)

Fernandes FAN, Rodrigues S. Dehydration of sapota (Achras sapota L.) using ultrasound as pretreatment. Dry. Technol. 26: 1232–1237 (2008b)

Fernandes FAN, Oliveira FIP, Rodrigues S. Use of ultrasound for dehydration of papayas. Food Bioprocess Technol. 1: 339–345 (2008)

Gamboa-Santos J, Montilla A, Cárcel JA, Villamiel M, Garcia-Perez JV. Air-borne ultrasound application in the convective drying of strawberry. J. Food Eng. 128: 132–139 (2014)

Garcia-Perez JV, Ortuño C, Puig A, Carcel JA, Perez-Munuera I. Enhancement of water transport and microstructural changes induced by high-intensity ultrasound application on orange peel drying. Food Bioprocess Technol. 5: 2256–2265 (2012)

Garcia-Perez JV, Carcel JA, Simal S, García-Alvarado MA, Mulet A. Ultrasonic intensification of grape stalk convective drying: Kinetic and energy efficiency. Dry. Technol. 31: 942–950 (2013)

He Z, Zhang Y, Wang Z, Zhao Z, Yi S. Reducing wood drying time by application of ultrasound pretreatment. Dry. Technol. 34: 1141–1146 (2016)

Jambrak AR, Mason TJ, Paniwnyk L, Lelas V. Accelerated drying of button mushrooms, Brussels sprouts and cauliflower by applying power ultrasound and its rehydration properties. J. Food Eng. 81: 88–97 (2007)

Kadam SU, Tiwari BK, O’Donnell CP. Effect of ultrasound pre-treatment on the drying kinetics of brown seaweed Ascophyllum nodosum. Ultrason. Sonochem. 23: 302–307 (2015)

Lewicki PP. Some remarks on rehydration of dried foods. J. Food Eng. 36: 81–87 (1998)

Nowacka M, Wiktor A, Śledź M, Jurek N, Witrowa-Rajchert D. Drying of ultrasound pretreated apple and its selected physical properties. J. Food Eng. 113: 427–433 (2012)

Ozuna C, Cárcel JAA, Walde PMM, Garcia-Perez JVV. Low-temperature drying of salted cod (Gadus morhua) assisted by high power ultrasound: Kinetics and physical properties. Innov. Food Sci. Emerg. Technol. 23: 146–155 (2014a)

Ozuna C, Gómez Álvarez-Arenas T, Riera E, Cárcel JA, Garcia-Perez JV. Influence of material structure on air-borne ultrasonic application in drying. Ultrason. Sonochem. 21:1235–1243 (2014b)

Puig A, Perez-Munuera I, Carcel JA., Hernando I, Garcia-Perez JV. Moisture loss kinetics and microstructural changes in eggplant (Solanum melongena L.) during conventional and ultrasonically assisted convective drying. Food Bioprod. Process. 90: 624–632 (2012)

Rodríguez Ó, Santacatalina JV, Simal S, Garcia-Perez JV, Femenia A, Rosselló C. Influence of power ultrasound application on drying kinetics of apple and its antioxidant and microstructural properties. J. Food Eng. 129: 21–29 (2014)

Sabarez HT, Gallego-Juarez JA, Riera E. Ultrasonic-assisted convective drying of apple slices. Dry. Technol. 30: 989–997 (2012)

Santacatalina JV, Contreras M, Simal S, Cárcel JA, Garcia-Perez JV. Impact of applied ultrasonic power on the low temperature drying of apple. Ultrason. Sonochem. 28: 100–109 (2016)

Schössler K, Thomas T, Knorr D. Modification of cell structure and mass transfer in potato tissue by contact ultrasound. Food Res. Int. 49: 425–431 (2012)

Śledź M, Nowak P, Witrowa-Rajchert D. Drying of parsley leaves pre-treated by ultrasound. Zesz. Probl. Postępów Nauk Rol. 579: 91–99 (2014)

Sledz M, Wiktor A, Rybak K, Nowacka M, Witrowa-Rajchert D. The impact of ultrasound and steam blanching pre-treatments on the drying kinetics, energy consumption and selected properties of parsley leaves. Appl. Acoust. 103: 148–156 (2016)

Sledz M, Wiktor A, Nowacka M, Witrowa-Rajchert D. Drying kinetics, microstructure and antioxidant properties of basil treated by ultrasound. J. Food Process Eng. 40: e12271 (2017)

Srikiatden J, Roberts JS. Predicting moisture profiles in potato and carrot during convective hot air drying using isothermally measured effective diffusivity. J. Food Eng. 84: 516–525 (2008)

Taghian Dinani S, Hamdami N, Shahedi M, Havet M. Mathematical modeling of hot air/electrohydrodynamic (EHD) drying kinetics of mushroom slices. Energy Convers. Manag. 86: 70–80 (2014a)

Taghian Dinani S, Havet M, Hamdami N, Shahedi M. Drying of mushroom slices using hot air combined with an Electrohydrodynamic (EHD) drying system. Dry. Technol. 32:597–605 (2014b)

Taghian Dinani S, Havet M. Effect of voltage and air flow velocity of combined convective-electrohydrodynamic drying system on the physical properties of mushroom slices. Ind. Crops Prod. 70: 417–426 (2015)

Taghian Dinani S, Hamdami N, Shahedi M, Havet M. Quality assessment of mushroom slices dried by hot air combined with an electrohydrodynamic (EHD) drying system. Food Bioprod. Process. 94: 572–580 (2015)

Taylor C, Clemente G, Sanjuán N, Cárcel JA, Mulet A. Influence of temperature, air velocity, and ultrasound application on drying kinetics of grape seeds. Dry. Technol. 32: 68–76 (2014)

Acknowledgements

The authors would like to express their gratitude to Islamic Azad University, Shahreza Branch for its financial support of this research.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Jarahizadeh, H., Taghian Dinani, S. Influence of applied time and power of ultrasonic pretreatment on convective drying of potato slices. Food Sci Biotechnol 28, 365–376 (2019). https://doi.org/10.1007/s10068-018-0464-4

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10068-018-0464-4