Abstract

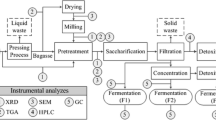

Pretreatments with different concentrations of sulfuric acid (0, 0.5, and 1% v/v) and temperatures (28 and 121 °C at 103 kPa in an autoclave) were performed on banana peels (BP) milled by mechanical grinding and grinding in a blender as well as without grinding. Cellulose, hemicellulose, lignin, ash, and total and reducing sugar contents were evaluated. The highest yields of cellulose enzymatic hydrolysis (99%) were achieved with liquefied autoclaved BP treated with 0.5 and 1% acid after 48 h of hydrolysis. Ethanol production by Kluyveromyces marxianus fermentation was assayed using hydrolyzed BP at 10, 15, and 20% (w/w). The highest ethanol level (21 g/L) was reached after 24 h of fermentation with 20% (w/w) BP. Kinetics of the consumption of reducing sugars under this fermentation condition demonstrates the presence of a lag period (about 8 h). Thus, BP are a good source for ethanol production.

Similar content being viewed by others

References

Oberoi HS, Vadlani PV, Saida L, Bansal S, Hughes JD. Ethanol production from banana peels using statistically optimized simultaneous saccharification and fermentation process. Waste Manage. 31: 1576–1584 (2011)

Palacios-Ponce S, Ilyina A, Ramos-González R, Ruiz HA, Martínez-Hernández JL, Segura-Ceniceros EP, Aguilar MA, Sánchez O, Aguilar CN. Bioproducts obtained from the bioprocessing of the banana peel waste: an Overview. In: Applied Chemistry and Chemical Engineering. Vol. 5. Research Methodologies in Modern Chemistry and Applied Science. Part II - 10. Eds: Haghi AK, Faria Ribeiro AC, Pogliani L, Balköse D, Francisco Torrens F, Omari V, Mukbaniani OV. CRC Press. Taylor and Francis Group. India. (2017) (in Press)

Nagarajaiah SB, Prakash J. Chemical composition and antioxidant potential of peels from three varieties of banana. As. J. Food Ag-Ind. 4: 31–46 (2011)

Souza O, Schulz MA, Fischer GAA, Wagner TM, Sellin N. Energia alternativa de biomassa: Bioetanol a partir de casca e polpa de banana. Rev. Bras. Eng. Agr. Ambient. 16: 915–921 (2012)

Velásquez-Arredondo HI, Ruiz-Colorado AA, De Oliveira junior S. Ethanol production process from banana fruit and its lignocellulosic residues: Energy Analysis. Energy. 35: 3081–3087 (2010)

Dhabekar A, Chandak A. Utilization of banana peels and beet waste for alcohol production. Asiatic. J. Biotechnol. Res. 1: 8–13 (2010)

Clarke WP, Radnidge P, Lai TE, Jensen PD, Hardin MT. Digestion of waste bananas to generate energy in Australia. Waste Manage. 28: 527–533 (2008)

Ilori MO, Adebusoye SA, Iawal AK, Awotiwon OA. Production of biogas from banana and plantain peels. Adv. Environ. Biol. 1: 33–38 (2007)

Bardiya N, Somayaji D, Khanna S. Biomethanation of banana peel and pineapple waste. Bioresour. Technol. 58: 73–76 (1996)

Gunaseelan VN. Biochemical methane potential of fruits and vegetable solid waste feedstocks. Biomass Bioenerg. 26: 389–399 (2004)

Pérez J, Muñoz-Dorado J, De la Rubia T, Martínez J. Biodegradation and biological treatments of cellulose, hemicellulose and lignin: an overview. Int. Microbiol. 5: 53–63 (2002)

Ovando-Chacó SL, Waliszewski KN. Commercial cellulases preparations and their applications in extractives processes. Universidad y Ciencia 21: 111–120 (2005)

Carmen S. Lignocellulosic residues: Biodegradation and bioconversion by fungi. Biotechnol. Adv. 27: 185–194 (2009)

Badui DS. Hidratos de carbono. 107-113. In: Química de los alimentos. Ed: Duarte EQ. Cuarta Edición. Pearson Educación. México (2006)

Sharma N, Kalra KL, Oberoi H, Bansal S. Optimization of fermentation parameters for production of ethanol from kinnow waste and banana peels by simultaneous saccharification and fermentation. Indian J. Microbiol. 47 (4): 310–316 (2007)

Itelima J, Onwuliri E, I. O, Oforji S. Bio-Ethanol Production from Banana, Plantain and Pineapple Peels by Simultaneous Saccharification and Fermentation Process. Int. J. Environ. Sci. Dev. 4 (2): 213–216 (2013)

Hendriks ATWM, Zeeman G. Pretreatments to enhance the digestibility of lignocellulosic biomass. Bioresour. Technol. 100 (1): 10–18 (2009)

Happi Emaga T, Andrianaivo RH, Wathelet B, Tchango JT, Paquot M. Effects of the stage of maturation and varieties on the chemical composition of banana and plantain peels. Food Chem. 103 (2): 590–600 (2007)

Happi Emaga T, Robert C, Ronkart SN, Wathelet B, Paquot M. Dietary fibre components and pectin chemical features of peels during ripening in banana and plantain varieties. Bioresour. Technol. 99 (10): 4346–4354 (2008)

Oberoi HS, Sandhu SK, Vadlani PV. Statistical optimization of hydrolysis process for banana peels using cellulolytic and pectinolytic enzymes. Food Bioprod. Process. 90 (2): 257–265 (2012)

King BC, Donnelly MK, Bergstrom GC, Walker LP, Gibson DM. An optimized microplate assay system for quantitative evaluation of plant cell wall-degrading enzyme activity of fungal culture extracts. Biotechnol. Bioeng. 102 (4): 1033–1044 (2009)

Happi Emaga T, Andrianaivo RH, Wathelet B, Tchango JT, Paquot M. Effects of the stage of maturation and varieties on the chemical composition of banana and plantain peels. Food Chem. 103: 590–600 (2007)

Li A, Antizar-Ladislao B, Khraisheh M. Bioconversion of municipal solid waste to glucose for bio-ethanol production. Bioprocess Biosyst. Eng. 30 (3):189–196 (2007)

Negro MJ, Ballesteros I, Manzanares P, Oliva JM, Sáez F, Ballesteros M. Inulin-containing biomass for ethanol production. Appl. Biochem. Biotechnol. 132 (1): 922–932 (2006)

Wilkins MR, Suryawati L, Maness NO, Chrz D. Ethanol production by Saccharomyces cerevisiae and Kluyveromyces marxianus in the presence of orange-peel oil. World J. Microbiol. Biotechnol. 23 (8): 1161–1168 (2007)

Mosier N, Wyman C, Dale B, Elander R, Lee YY, Holtzapple M, Ladisch M. Features of promising technologies for pretreatment of lignocellulosic biomass. Bioresour. Technol. 96: 673–686 (2005)

Hammond JB, Egg R, Diggins D, Coble CG. Alcohol from bananas. Bioresour. Technol. 56 (1): 125–130 (1996)

Oberoi HS, Sandhu SK, Vadlani PV. Statistical optimization of hydrolysis process for banana peels using cellulolytic and pectinolytic enzymes. Food Bioprod. Process. 90: 257–265 (2012)

Oberoi HS, Vadlani PV, Saida L, Bansal S, Hughes JD. Ethanol production from banana peels using statistically optimized simultaneous saccharification and fermentation process. Waste Manag. 31: 1576–1584 (2011)

Cortés-Arganda JF, Ramos-González R, Segura-Ceniceros EP, Martínez-Hernández JL, Rutiaga Quiñones OM, Iliná A. Screening of Kluyveromyces marxianus strains for ethanol production. II435. In: IAFP’s 5th Latin American Symposium in Food Safety, 7th Food Science, Biotechnology and Safety Meeting. November 9–11, Convention Center, Cancún. Mexico (2016)

Zhang Q, Wu D, Lin Y, Wang X, Kong H, Tanaka S. Substrate and product inhibition on yeast performance in ethanol fermentation. Energy Fuels 29: 1019–1027 (2015)

Acknowledgements

Authors would thank to the Mexican National Council of Science and Technology (CONACYT) for the financial support of the project PDCPN 2013-01-213844, Ph.D. scholarship, and for the financial support under the program “Cátedras-CONACyT” (Researcher No. 2498).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

All authors declare that they have no conflict of interest.

Rights and permissions

About this article

Cite this article

Palacios, S., Ruiz, H.A., Ramos-Gonzalez, R. et al. Comparison of physicochemical pretreatments of banana peels for bioethanol production. Food Sci Biotechnol 26, 993–1001 (2017). https://doi.org/10.1007/s10068-017-0128-9

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10068-017-0128-9