Abstract

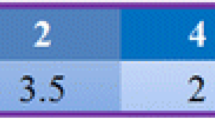

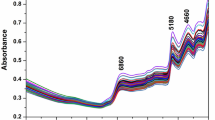

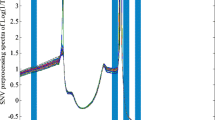

Catechin content, the ratio of tea polyphenols and free amino acids (TP/FAA), as well as the ratio of theaflavins and thearubigins (TFs/TRs) are important biochemical indicators to evaluate fermentation quality. To achieve rapid determination of such biochemical indicators, synergy interval partial least square and extreme learning machine combined with an adaptive boosting algorithm, Si-ELM-AdaBoost algorithm, were used to establish quantitative analysis models between near infrared spectroscopy (NIRS) and catechin content and between TFs/TRs and TP/FAA, respectively. The results showed that prediction performance of the Si-ELM-AdaBoost mixed algorithm is superior than that of other models. The prediction results with root-mean-square error of prediction ranged from 0.006 to 0.563, the ratio performance deviation values exceeded 2.5, and predictive correlation coefficient values exceeded 0.9 in the prediction model of each biochemical indicator. NIRS combined with Si-ELM-AdaBoost mixed algorithm could be utilized for online monitoring of black tea fermentation. Meanwhile, the AdaBoost algorithm effectively improved the accuracy of the ELM model and could better approach the nonlinear continuous function.

Similar content being viewed by others

References

Owuor PO, Obanda M, Nyirenda HE, Mandala WL. Influence of region of production on clonal black tea chemical characteristics. Food Chem. 108: 263–271 (2008)

Roberts E. The chemistry of tea manufacture. J. Sci. Food Agr. 9: 381–390 (1958)

Muthumani T, Kumar RS. Influence of fermentation time on the development of compounds responsible for quality in black tea. Food Chem. 101: 98–102 (2007)

Ghosh A, Tamuly P, Bhattacharyya N, Tudu B, Gogoi N, Bandyopadhyay R. Estimation of theaflavin content in black tea using electronic tongue. J. Food Eng. 110: 71–79 (2012)

Sharma P, Ghosh A, Tudu B, Sabhapondit S, Baruah BD, Tamuly P, Bhattacharyya N, Bandyopadhyay R. Monitoring the fermentation process of black tea using QCM sensor based electronic nose. Sensor. Actuat. B-Chem. 219: 146–157 (2015)

Gill G, Kumar A, Agarwal R. Monitoring and grading of tea by computer vision–A review. J. Food Eng. 106: 13–19 (2011)

Muthumani T, Kumar R. Influence of fermentation time on the development of compounds responsible for quality in black tea. Food Chem. 101: 98–102 (2007)

Cai J, Chen Q, Wan X, Zhao J. Determination of total volatile basic nitrogen (TVB-N) content and Warner–Bratzler shear force (WBSF) in pork using Fourier transform near infrared (FT-NIR) spectroscopy. Food Chem. 126: 1354–1360 (2011)

Chen Q, Ding J, Cai J, Sun Z, Zhao J. Simultaneous measurement of total acid content and soluble salt-free solids content in chinese vinegar using near-infrared spectroscopy. J. Food Sci. 77: C222–C227 (2012)

Chen Q, Zhang D, Pan W, Ouyang Q, Li H, Urmila K, Zhao J. Recent developments of green analytical techniques in analysis of tea’s quality and nutrition. Trends Food Sci. Tech. 43: 457–458 (2015)

Li X, Nie P, Qiu Z, et al. Using wavelet transform and multi-class least square support vector machine in multi-spectral imaging classification of Chinese famous tea. Expert. Syst. Appl. 38: 11149–11159 (2015)

Borah S, Bhuyan M. A computer based system for matching colours during the monitoring of tea fermentation. Int. J. Food Sci. Tech. 40: 675–682 (2005)

Huang GB, Chen L. Enhanced random search based incremental extreme learning machine. Neurocomputing. 71: 3460–3468 (2008)

Huang GB, Zhu QY, Siew CK. Extreme learning machine: theory and applications. Neurocomputing. 70: 489–501 (2006)

Freund Y, Schapire RE. A decision-theoretic generalization of on-line learning and an application to boosting. J. Comput. Syst. Sci. 55: 119–139 (1997)

Mir-Marqués A, Elvira-Sáez C, Cervera ML, Garrigues S, Guardia MDL. Authentication of protected designation of origin artichokes by spectroscopy methods. Food Control. 59: 74–81 (2016)

Lee M, Hwang Y, Lee J, Choung M. The characterization of caffeine and nine individual catechins in the leaves of green tea (Camellia sinensis L.) by near-infrared reflectance spectroscopy. Food Chem. 158: 351–357 (2014)

Ouyang Q, Zhao J, Chen Q. Measurement of non-sugar solids content in Chinese rice wine using near infrared spectroscopy combined with an efficient characteristic variables selection algorithm. Spectrochim. Acta A. 151: 280–285 (2015)

Ouyang Q, Zhao J, Chen Q, Lin H, Sun Z. Rapid measurement of antioxidant activity in dark soy sauce by NIR spectroscopy combined with spectral intervals selection and nonlinear regression tools. Anal. Methods. 4: 940–946 (2012)

Qi S, Ouyang Q, Chen Q, Zhao J. Real-time monitoring of total polyphenols content in tea using a developed optical sensors system. J. Pharmaceut. Biomed. 97: 116–122 (2014)

Tan C, Li M. Mutual information-induced interval selection combined with kernel partial least squares for near-infrared spectral calibration. Spectrochim. Acta A. 71: 1266–1273 (2008)

Chen Q, Hu W, Su J, Li H, Ouyang Q, Zhao J. Nondestructively sensing of total viable count (TVC) in chicken using an artificial olfaction system based colorimetric sensor array. J. Food Eng. 168: 259–266 (2016)

Ouyang Q, Zhao J, Pan W, Chen Q. Real-time monitoring of process parameters in rice wine fermentation by a portable spectral analytical system combined with multivariate analysis. Food Chem. 190: 135–141 (2016)

Ouyang Q, Chen Q, Zhao J. Intelligent sensing sensory quality of Chinese rice wine using near infrared spectroscopy and nonlinear tools. Spectrochim. Acta A. 154: 42–46 (2016)

Ren G, Wang S, Ning J, Xu R, Wang Y, Xing Z, Wan X, Zhang Z. Quantitative analysis and geographical traceability of black tea using Fourier transform near-infrared spectroscopy (FT-NIRS). Food Res. Int. 53: 822–826 (2013)

Li X, Sun C, Luo L, He Y. Determination of tea polyphenols content by infrared spectroscopy coupled with iPLS and random frog techniques. Comput. Electron. Agr. 112: 28–35 (2015)

Acknowledgements

This work has been financially supported by the National Natural Science Foundation of China (31471646), the Natural Science Foundation of Zhejiang Province (Y16C160009), the Innovation Project of China Academy of Agricultural Sciences (CAAS-ASTIP-TRICAAS), and Science and Technology Project of Zhenjiang City (NY2016013).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare no conflict of interest.

Rights and permissions

About this article

Cite this article

Dong, C., Zhu, H., Wang, J. et al. Prediction of black tea fermentation quality indices using NIRS and nonlinear tools. Food Sci Biotechnol 26, 853–860 (2017). https://doi.org/10.1007/s10068-017-0119-x

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10068-017-0119-x