Abstract

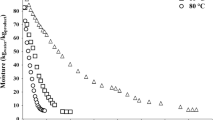

Uvaia (Eugenia pyriformis) frozen pulp processing generates a solid byproduct that can potentially contain important components of human nutrition. In this study, the drying of uvaia byproduct was studied. Two different drying treatments were tested: drying of wet waste and drying of waste with prior removal of water by centrifugation. Three drying temperatures were used: 40, 60, and 80 °C. Eight models were applied to fit the drying curves: Page, Lewis, Modified Page, Logarithmic, Midilli, Wang and Singh, Henderson and Pabis, and Weibull. Midilli presented an excellent fit to the curves. The effective moisture diffusivity of the uvaia byproduct ranged between 8.52 × 10−10 and 3.22 × 10−9 m2/s. The activation energy was 25.65 and 24.97 kJ/mol for non-centrifuged and centrifuged assays, respectively. The dried byproducts had a reduction of 3–21% of the total phenolic content against the control. The assay performed at 40 °C with centrifugation presented the lowest total color difference value.

Similar content being viewed by others

References

Djilas S, Canadanovic-Brunet J, Cetkovic G. By-products of fruits processing as a source of phytochemicals. Chem. Ind. Chem. Eng. Q. 15: 191–202 (2009)

Lousada Junior JE, Maria J, Neuman J, Neiva M. Caracterização físico-química de subprodutos obtidos do processamento de frutas tropicais visando seu aproveitamento na alimentação animal. Rev. Ciên. Agron. 37: 70–76 (2006)

Sousa M, Vieira L, Silva M da, Lima A de. Caracterização nutricional e compostos antioxidantes em resíduos de polpas de frutas tropicais. Ciênc. Agrotec. 35: 554–59 (2011)

Górnaś P, Rudzińska M. Seeds recovered from industry by-products of nine fruit species with a high potential utility as a source of unconventional oil for biodiesel and cosmetic and pharmaceutical sectors. Ind. Crops Prod. 83: 329–338 (2016)

O’Shea N, Rößle C, Arendt E, Gallagher E. Modelling the effects of orange pomace using response surface design for gluten-free bread baking. Food Chem. 166: 223–230 (2015)

Dias MV, Figueiredo LP, Valente WA, Ferrua FQ, Pereira PAP, Pereira AGT, Borges SV, Clemente PR. Estudo de variáveis de processamento para produção de doce em massa da casca do maracujá (passiflora edulis f. flavicarpa). Ciência e Tecnol. Aliment. 31: 65–71 (2011)

Ktenioudaki A, O’Shea N, Gallagher E. Rheological properties of wheat dough supplemented with functional by-products of food processing: brewer’s spent grain and apple pomace. J. Food Eng. 116: 362–368 (2013)

Ferreira MSL, Santos MCP, Moro TM, Basto GJ, Andrade RMS, Gonçalves ÉCB. Formulation and characterization of functional foods based on fruit and vegetable residue flour. J. Food Sci. Technol. 52: 822–830 (2015)

Madamba PS, Driscollb RH, Buckleb KA. The thin-layer drying characteristics of garlic slices. J. Food Eng. 29: 75–97 (1996)

Doymaz İ, Altıner P. Effect of pretreatment solution on drying and color characteristics of seedless grapes. Food Sci. Biotechnol. 21: 43–49 (2012)

Pereira MC, Steffens RS, Jablonski A, Hertz PF, Rios ADO. Characterization and antioxidant potential of Brazilian fruits from the Myrtaceae family. J. Agric. Food Chem. 60: 3061–3067 (2012)

Barreto GPM, Benassi MT, Mercadante AZ. Bioactive compounds from several tropical fruits and correlation by multivariate analysis to free radical scavenger activity. J. Braz. Chem. Soc. 20: 1856–1861 (2009)

Clerici MTPS, Carvalho-Silva LB. Nutritional bioactive compounds and technological aspects of minor fruits grown in Brazil. Food Res. Int. 44: 1658–1670 (2011)

Moura MS. Propriedades funcionais de frutas tropicais brasileiras não tradicionais. Ph.D. Thesis, Universidade Federal Rural do Semi-Árido, Mossoró, RN, Brazil (2008)

AOAC. Official Method of Analysis of AOAC Association of Official Analytical Chemists, Gaithersburg, MD, USA (2006)

Bligh EG, Dyer WJ. A rapid method for total lipid extraction and purification. Can. J. Biochem. Physiol. 37: 911–917 (1959)

Doymaz İ. Experimental study on drying characteristics of pomegranate peels. Food Sci. Biotechnol. 20: 965–970 (2011)

Falade KO, Solademi OJ. Modelling of air drying of fresh and blanched sweet potato slices. Int. J. Food Sci. Technol. 45: 278–288 (2010)

Demiray E, Tulek Y. Drying characteristics of garlic (Allium sativum L.) slices in a convective hot air dryer. Heat Mass Transf. 50: 779–786 (2014)

Wang Z, Sun J, Liao X, Chen F, Zhao G. Mathematical modeling on hot air drying of thin layer apple pomace. Food Res. Int. 40: 39–46 (2007)

Sadi T, Meziane S. Mathematical modelling, moisture diffusion and specific energy consumption of thin layer microwave drying of olive pomace. Int. Food Res. J. 22: 494–501 (2015)

Roberts J, Kidd D, Padilla-Zakour O. Drying kinetics of grape seeds. J. Food Eng. 89: 460–465 (2008)

Kara C, Doymaz I. Thin layer drying kinetics of by-products from pomegranate juice processing. J. Food Process. Preserv. 39: 480–487 (2015)

Crank J. The Mathematics of diffusion. Oxford University Press: London (1975)

Vega-gálvez A, Miranda M, Puente L, Lopez L, Rodriguez K, Di K. Effective moisture diffusivity determination and mathematical modelling of the drying curves of the olive-waste cake. Bioresour. Technol. 101: 7265–7270 (2010)

Alibas I. Mathematical modeling of microwave dried celery leaves and determination of the effective moisture diffusivities and activation energy. Food Sci. Technol. 34: 394–401 (2014)

Gokhale S V., Lele SS. Dehydration of red beet root (Beta vulgaris) by hot air drying: process optimization and mathematical modeling. Food Sci. Biotechnol. 20: 955–964 (2011)

Haminiuk CWI, Plata-Oviedo MSV, Guedes AR, Stafussa AP, Bona E, Carpes ST. Chemical, antioxidant and antibacterial study of Brazilian fruits. Int. J. Food Sci. Technol. 46: 1529–1537 (2011)

Hwa C, Lim C, Figiel A, Wojdyło A, Oziembłowski M. Colour, phenolic content and antioxidant capacity of some fruits dehydrated by a combination of different methods. Food Chem. 141: 3889–3896 (2013)

De Azevêdo JCS, Fujita A, de Oliveira EL, Genovese MI, Correia RTP. Dried camu-camu (Myrciaria dubia H.B.K. McVaugh) industrial residue: a bioactive-rich amazonian powder with functional attributes. Food Res. Int. 62: 934–940 (2014)

Romdhane NG, Bonazzi C, Kechaou N, Mihoubi NB. Effect of air-drying temperature on kinetics of quality attributes of lemon (Citrus limon cv. lunari) peels. Dry. Technol. 33: 1581–1589 (2015)

Bezerra CV, Meller da Silva LH, Corrêa DF, Rodrigues AMC. A modeling study for moisture diffusivities and moisture transfer coefficients in drying of passion fruit peel. Int. J. Heat Mass Transf. 85: 750–755 (2015)

Zillo RR, Silva PPM, Zanatta S, Carmo LF, Spotto MHF. Qualidade físico-química da fruta in natura e da polpa de uvaia congelada. Rev. Bras. Prod. Agroindusriais. 15: 293–298 (2013)

Ramirez MR, Schnorr CE, Feistauer LB, Apel M, Henriques AT, Moreira JCF, Zuanazzi JA. Evaluation of the polyphenolic content, anti-inflammatory and antioxidant activities of total extract from Eugenia pyriformes cambess (uvaia) fruits. J. Food Biochem. 36: 405–412 (2012)

Spoladore SF, Bissaro CA, Vieira TF, Silva MV, Haminiuk CWI, Demczuk B. Modelagem matemática da secagem de casca de maracujá e influência da temperatura na cor, compostos fenólicos e atividade antioxidante. Rev. Bras. Pesqui. em Aliment. 5: 17–25 (2014)

Acknowledgements

The present study was supported by the Cnpq (National Counsel of Technological and Scientific Development), process number 457190/2014-0. Cnpq also supported the first author with a doctorate scholarship and the third author with an undergraduate research scholarship.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare no conflict of interest.

Rights and permissions

About this article

Cite this article

Ramos, K.K., Lessio, B.C., Mecê, A.L.B. et al. Mathematical modeling of uvaia byproduct drying and evaluation of quality parameters. Food Sci Biotechnol 26, 643–651 (2017). https://doi.org/10.1007/s10068-017-0078-2

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10068-017-0078-2