Abstract

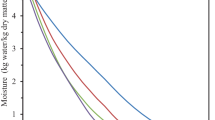

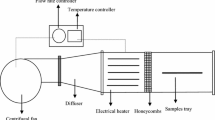

The effect of temperature on the drying kinetics of pear slices was investigated. The drying process was carried out at temperatures of 55, 65, and 75°C. Drying time decreased considerably with increased air temperature. Seven mathematical models available in the literature were tested with the drying patterns. The Wang and Singh, and Midilli et al. models were given the best results in describing drying of pear slices. Effective moisture diffusivity increased with increasing air temperature, and varied from 0.85 to 2.18×10−10 m2/s over the temperature range investigated, with activation energy equal to 44.78 kJ/mol.

Similar content being viewed by others

References

Park KJ, Bin A, Brod FPR. Drying of pear ‘d’Anjou’ with and without osmotic dehydration. J. Food Eng. 56: 93–103 (2002)

FAO.FaoStat: Agriculture Data. http://faostat.fao.org/site/567/DesktopDefault.aspx?PageID=567#ancor. Accessed February 23, 2012.

Fumagalli F, Silveria AM. Quality evaluation of microwave-dried ‘Packham’s Triumph’ pear. Dry. Technol. 23: 2215–2226 (2005)

Falade KO, Solademi OJ. Modelling of air drying of fresh and blanched sweet potato slices. Int. J. Food Sci. Tech. 45: 278–288 (2010)

Guiné RPF. Moisture diffusivity in pears: Experimental determination and derivation of a mathematical prediction model. Int. J. Food Sci. Tech. 41: 1177–1181 (2006)

Sacilik K, Elicin AK, Unal G. Drying kinetics of ‘Uryani’ plum in a convective hot-air dryer. J. Food Eng. 76: 362–368 (2006)

McMinn WAW. Thin-layer modelling of the convective, microwave, microwave-convective, and microwave-vacuum drying of lactose powder. J. Food Eng. 72: 113–123 (2006)

Togrul, IT, Pehlivan D. Modelling of thin layer drying kinetics of some fruits under open-air sun drying process. J. Food Eng. 65: 413–425 (2003)

Doymaz I. Effect of pre-treatments using potassium metabisulphide and alkaline ethyl oleate on the drying kinetics of apricots. Biosyst. Eng. 89: 281–287 (2004)

Babalis SB, Belessiotis V. Influence of the drying conditions on the drying constants and moisture diffusivity during the thin-layer drying of figs. J. Food Eng. 65: 449–458 (2004)

Sabarez HT, Price WE. A diffusion model for prune dehydration. J. Food Eng. 42: 167–172 (1999)

Goyal RK, Kingsly ARP, Manikantan MR, Ilyas MR. Mathematical modelling of thin layer drying kinetics of plum in a tunnel dryer. J. Food Eng. 79: 176–180 (2007)

Akpinar EK, Bicer Y, Midilli A. Modelling and experimental study on drying of apple slices in a convective cyclone dryer. J. Food Process Eng. 26: 515–541 (2003)

Seiiedlou S, Ghasemzadeh HR, Hamdami N, Talati F, Moghaddam M. Convective drying of apple: Mathematical modelling and determination of some quality parameters. Int. J. Agr. Biol. 12: 171–178 (2010)

Tarhan S, Ergunes G, Taser OF. Selection of chemical and thermal pre-treatment combination to reduce the dehydration time of sour cherry (Prunus cerasus L.). J. Food Process Eng. 29: 651–663 (2006)

Djendoubi Mrad ND, Boudhriona N, Kechaou N, Courtois F, Bonazzi C. Influence of air drying temperature on kinetics, physicochemical properties, total phenolic content and ascorbic acid of pears. Food Bioprod. Process. 90: 433–441 (2011)

Roberts JS, Kidd DR, Padilla-Zakour O. Drying kinetics of grape seeds. J. Food Eng. 89: 460–465 (2008)

Ghodake HM, Goswami TK, Chakraverty A. Mathematical modelling of withering characteristics of tea leaves. Dry. Technol. 24: 159–164 (2006)

Vega-Gálvez A, Ayala-Aponte A, Notte E, De La Fuente L, Lemus-Mondaca R. Mathematical modelling of mass transfer during convective dehydration of brown algae Macrocystis pyrifera. Dry. Technol. 26: 1610–1616 (2008)

Akpinar EK. Mathematical modelling and experimental investigation on sun and solar drying of white mulberry. J. Mech. Sci. Technol. 22: 1544–1553 (2008)

Shen F, Peng L, Zhang Y, Wu J, Zhang X, Yang G, Peng H, Qi H. Thin-layer drying kinetics and quality changes of sweet sorghum stalk for ethanol production as affected by drying temperature. Ind. Crop. Prod. 34: 1588–1594 (2011)

Dissa AO, Bathiebo DJ, Desmorieux H, Coulibaly O, Koulidiati J. Experimental characterization and modelling of thin layer direct solar drying of ‘Amelia’ and ‘Brooks’ mangoes. Energy 36: 2517–2527 (2011)

Perea-Flores MJ, Garibay-Febles V, Chanona-Pérez JJ, Calderón-Domínguez G, Méndez-Méndez JV, Palacios-González E, Gutiéerrez-López GF. Mathematical modelling of castor oil seeds (Ricinus communis) drying kinetics in fluidized bed at high temperatures. Ind. Crop Prod. 38: 64–71 (2012)

Sobukola OP, Dairo OU, Odunewu AV. Convective hot air drying of blanched yam slices. Int. J. Food Sci. Tech. 43: 1233–1238 (2008)

Lee JH, Kim HJ. Modelling for vacuum drying characteristics of onion slices. Food Sci. Biotechnol. 18: 1293–1297 (2009)

Crank J. Diffusion in a plane sheet. pp. 43–61. In: The Mathematics of Diffusion. Clarendon Press, Inc., Oxford, UK (1975)

Zogzas NP, Maroulis ZB, Marinos-Kouris D. Moisture diffusivity data compilation in foodstuffs. Dry. Technol. 14: 2225–2253 (1996)

Azzouz S, Guizani A, Jomaa W, Belghith A. Moisture diffusivity and drying kinetic equation of convective drying of grapes. J. Food Eng. 55: 323–330 (2002)

Rafiee S, Sharifi M, Keyhani A, Omid M, Jfari A, Mohtasebi SS, Mobli H. Modelling effective moisture diffusivity of orange slice (Thomson Cv.). Int. J. Food Prop. 13: 32–40 (2010)

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Doymaz, İ., İsmail, O. Experimental characterization and modelling of drying of pear slices. Food Sci Biotechnol 21, 1377–1381 (2012). https://doi.org/10.1007/s10068-012-0181-3

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10068-012-0181-3