Abstract

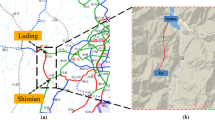

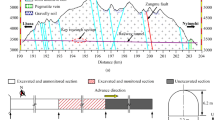

To solve stability issues of super large cross-sectional tunnel with greater than 20 m across and an overall area greater than 314 m2 during excavation, a new technique named cross rock pillar method (CRPM) is proposed. A physical model test was firstly conducted to investigate the deformation and failure mechanisms of a tunnel using CRPM. In this physical model, a rock-like material simulating the V-class surrounding rock was made and a geomechanical model test bench was developed to simulate and observe the progressive failure process of the tunnel. Furthermore, fiber sensing technology was used to continuously monitor the horizontal strain in different cross sections. Test results show that the cross rock pillars play a significant role in preventing deformation of the surrounding rock during the tunnel excavation. A numerical model was then established to verify the results obtained by the physical model test. The deformation and stability mechanisms of the surrounding rock are determined using CRPM in super large cross-sectional tunnels. Finally, the proposed CRPM was successfully implemented in the Hongqihegou rail station, and the monitoring results show that the surrounding rock was adequately controlled throughout the excavation process.

Similar content being viewed by others

Data availability

Some or all data, models, or code that support the findings of this study are available from the corresponding author upon reasonable request.

Abbreviations

- b 1 :

-

Radius of the circular tunnel

- B :

-

Calculated width of the slip surface

- C :

-

Cohesion

- C E :

-

Elastic modulus similarity ratio

- C f :

-

Internal friction angle similarity ratio

- C L :

-

Geometric similarity ratio

- Cr:

-

Unit weight similarity ratio

- C ε :

-

Strain similarity ratio

- C σ :

-

Compressive strength similarity ratio

- C μ :

-

Poisson’s ratio similarity ratio

- C φ :

-

Friction coefficient similarity ratio

- h 0 :

-

Carven height

- H :

-

Buried depth

- L1 :

-

Strength envelope before support

- L2 :

-

Strength envelope after support

- L AB :

-

Length of initial fiber

- U A :

-

Displacement of the point A

- U B :

-

Displacement of the point B

- ∆U :

-

Relative displacement of interval Z1 and Z2; when Z1 is fixed, ∆U is the displacement of Z2

- ε AB :

-

Strain value of the fiber at the monitoring point in interval A and B.

- ε(Z):

-

Strain value of the fiber at the monitoring point in interval Z1 and Z2.

- σ n0(σ n1,σ n2):

-

Normal stress

- σ t0(σ t1,σ t2):

-

Tangential stress

- φ :

-

Internal friction angle

- CD:

-

Center diaphragm

- CRD:

-

Cross diaphragm

- CRPM:

-

Cross rock pillar method

- EMI:

-

Electromagnetic interference

- FFT:

-

Fast Fourier transform

- FMCW:

-

Frequency modulated continuous wave

- LO:

-

Local oscillator

- OFDR:

-

Optical frequency domain reflectometry

References

Bandini A, Berry P, Cormio C, Colaiori M, Lisardi A (2017) Safe excavation of large section tunnels with Earth Pressure Balance Tunnel Boring Machine in gassy rock masses: the Sparvo tunnel case study. Tun under Sp Tech 67:85–97

Chai J, Zhang DD, Li Y (2015) Research progress of optical fiber sensing technology in geotechnical and geological engineering. J Architect Civil Eng 32(03):28–37 (in Chinese)

Chan THT, Yu L, Tam HY, Ni YQ, Liu SY, Chung WH, Cheng LK (2006) Fiber Bragg grating sensors for structural health monitoring of Tsing Ma bridge: background and experimental observation. Eng Struct 28(5):648–659

Chen H, Ren WZ (2015) Development of epoxy-silicone rubber-based geotechnical similar material and its engineering application. Mater Res Innov 19(sup 5):S5-296-S5-300

Cheng XS, Zhang XY, Chen WJ, Xu WW, Du XL (2017) Stability analysis of a cross-sea tunnel structure under seepage and a bidirectional earthquake. Int J Geomech. https://doi.org/10.1061/(ASCE)GM.1943-5622.0000937

Cui X, Sun S, Wang G, Hou M (2010) Comparison and contrast between CRD excavation method and 3-bench 7-step excavation method and their optimization. Tunnel Construction. (in Chinese)

Das R, Singh PK, Kainthola A, Panthee S, Singh TN (2017) Numerical analysis of surface subsidence in asymmetric parallel highway tunnels. J Rock Mech Geotech Eng 9(1):170–179

Ding ZY (2013) Methods for improving OFDR performances and their experimental verifications [Ph.D. thesis]. Tianjin University

Feng G, Zhou KP, Dong WJ, Su JH (2008) Similar material simulation of time series system for induced caving of roof in continuous mining under backfill. J Cent South Univ 15(3):356–360

Flynn EB, Todd MD (2010) A Bayesian approach to optimal sensor placement for structural health monitoring with application to active sensing. Mech Syst Signal Pr 24(4):891–903

Fumagalli E (1973) Statical and geomechanical models. https://doi.org/10.1007/978-3-7091-8317-5

Guowei M, Hebin Z, Pengfei L (2018) Displacement characteristics for a “π” shaped double cross-duct excavated by cross diaphragm (CRD) method. Tun under Sp Tech 2018(77):204–215

Huang X, Schweiger HF, Huang H (2014) Influence of deep excavations on nearby existing tunnels. Int J Geomech 13(2):170–180

Ito F, Fan X, Koshikiya Y (2012) Long-range coherent OFDR with light source phase noise compensation. J Lightwave Technol 30(8):1015–1024

Kamata H, Mashimo H (2003) Centrifuge model test of tunnel face reinforcement by bolting. Tunn Undergr Space Technol 18(2):205–212

Karakus M, Fowell RJ (2003) Effect of different tunnel face advance excavation on the settlement by FEM. Tun under Sp Tech 18(5):513–523

Lan Y, Fang Y, Duan SH, Zhong S (2009) Numerical simulation for construction of metro shield tunnel undercrossing Jinjiang Bridge. J Railway Eng Soc

Lee B (2003) Review of the present status of optical fiber sensors. Opt Fiber Tech Mater Devices Syst 9(2):57–79 (in Chinese)

Lei MF, Lin DY, Yang WC, Shi CH, Peng LM, Huang J (2016) Model test to investigate failure mechanism and loading characteristics of shallow-bias tunnels with small clear distance. J Cent South Univ 23(12):3312–3321

Li P, Zhao Y, Zhou X (2016) Displacement characteristics of high-speed railway tunnel construction in loess ground by using multi-step excavation method. Tunn Undergr Space Technol 2016(51):41–55

Li SC, Wang DC, Wang Q, Wang FQ, Peng P, Li WT, Jiang B, Wang HT (2013) Development and application of large-scale geomechanical model test system for deep thick top coal roadway. J China Coal Soc 38(09):1522–1530 (in Chinese)

Li WH, Zhao DJ, Zhou SS (2012) Numerical simulation analysis and engineering applications on the double-side-wall heading step bench excavation of large-cross section and shallow tunnel. Adv Mater Res 594–597:1182–1187

Liu QS, Peng XX, Lei GF, Wang JT, Zhang J, Xiao LG (2017) Geomechanical model test on excavation technology of supper-large cross-section ultra-shallow tunnel with cross rock pillar method. Rock Soil Mech 38(10):2780–2788 (in Chinese)

Lu L, Kong XJ, Dong Y, Zou DG, Zhou Y (2017) Similarity relationship for brittle failure dynamic model experiment and its application to a concrete dam subjected to explosive load. Int J Geomech. https://doi.org/10.1061/(ASCE)GM.1943-5622.0000889

Luo Y, Chen J, Gao S, Deng X, Diao P (2017) Stability analysis of super-large-section tunnel in loess ground considering water infiltration caused by irrigation. Environ Earth Sci 76(22):763

Mandal SK, Singh MM (2009) Evaluating extent and causes of overbreak in tunnels. Tunn Undergr Space Technol 24(1):22–36

Minh NV, Wout B, Johan WB (2017) Structural analysis for shallow tunnels in soft soils. Int J Geomech 17(1)

Mitelman A, Elmo D (2014) Modelling of blast-induced damage in tunnels using a hybrid finite-discrete numerical approach. J Rock Mech Geotech Eng 6(6):565–573

Moosavi E, Shirinabadi R, Rahimi E, Gholinejad M (2018) Numerical modeling of ground movement due to twin tunnel structure of Esfahan subway. Iran J Min Sci 53(4):663–675

Ng CWW, Fong KY, Liu HL (2018) The effects of existing horseshoe-shaped tunnel sizes on circular crossing tunnel interactions: three-dimensional numerical analyses. Tunn Undergr Space Technol 77:68–79

Shahin HM, Nakai T, Ishii K, Iwata T, Kuroi S (2016) Investigation of influence of tunneling on existing building and tunnel: model tests and numerical simulations. Acta Geotech 11(3):679–692

Sari YD, Pasamehmetoglu AG, Cetiner E, Donmez S (2016) Numerical analysis for a realistic support design: case study of the Komurhan tunnel in eastern Turkey. Int J Geomech 8(1):74–81

Sharifzadeh M, Kolivand F, Ghorbani M, Yasrobi S (2013) Design of sequential excavation method for large span urban tunnels in soft ground – Niayesh tunnel. Tunn Undergr Space Technol 35:178–188

Wang FX, Tie DY, Zhang HY, Zhang C (2005) Analysis and imitation of tunnel construction by FEM. J. Shenyang Archit Civil Eng Inst

Xue F, Ma J, Yan L, Zhao Y (2010) Three-dimension FEM analysis of large cross-section tunnel in collapsible loess constructed by CRD method. GeoFlorida 2349–2358

Yan C, Jiao YY, Yang S (2019) A 2D coupled hydro-thermal model for the combined finite-discrete element method. Acta Geotech 14(2):403–416

Yang J, Yang J, Yan L, Zhang H, Hu X, Tang P (2012) Construction scheme choice of large-span tunnels under-passing high voltage transmission tower and its application. Chin J Rock Mech Eng 31(06):1184–1191

Zhang QY, Li SC, Li Y, Chen XG (2012a) New method, new technology and engineering application of underground engineering model test. Press, Sci

Zhang ZX, Xu Y, Kulatilake PHSW, Huang X (2012b) Physical model test and numerical analysis on the behavior of stratified rock masses during underground excavation. Int J Rock Mech Min 49(49):134–147

Zhao C, Lavasan AA, Barciaga T, Kamper C, Mark P, Schanz T (2017) Prediction of tunnel lining forces and deformations using analytical and numerical solutions. Tun under Sp Tech 64:164–176

Zuo BC, Chen CX, Liu CH, Shen Q, Xiao GF, Liu XW (2004) Research on similar material of slope simulation experiment. Rock Soil Mech 25(11):1805–1808 (in Chinese)

Acknowledgements

The authors are grateful to the editor and reviewer for their helpful comments and constructive suggestions in improving this paper.

Funding

This work was financially supported by National Natural Science Foundation of China under Grant Nos. 51974289 and 42177140. The anonymous reviewers are also deeply acknowledged for reviewing this article and giving their valuable comments.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare no competing interests.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Sang, H., Liu, B., Kang, Y. et al. Experimental and numerical investigations on cross rock pillar method for super large cross-sectional tunnel excavation. Bull Eng Geol Environ 82, 274 (2023). https://doi.org/10.1007/s10064-023-03316-y

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s10064-023-03316-y