Abstract

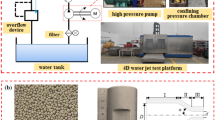

When highly abrasive hard rock strata are encountered during the TBM boring process, severe problems, such as low TBM boring efficiency and severe tool wear, emerge. High-pressure water jet-assisted TBM rock breaking technique has been developed and applied in steps. In this study, the effect of confining pressure and precutting slits on the penetration damage in highly abrasive hard rock is studied through TBM cutter penetration tests. Some main conclusions are drawn as follows: (1) For intact rock samples, the increase in confining pressure leading to a reduction in the unloading effect after the initial crack emerges when the confining pressure is higher than 15 MPa. Meanwhile, the boreability of the highly abrasive hard rock also significantly decreases, making it more difficult for rock breaking. (2) When examining the penetration damage process of intact and pre-cutting rock samples, a similar contact compaction stage (stage I) and microcrack initiation stage (stage II) can be found, while the crack propagation-penetration damage stage (stage III) shows significant differences in rock fragmentation patterns and force-penetration depth curve characteristics. (3) Under high confining pressure, precutting slits can enhance the initial decrease of the force by increasing the unloading effect of the TBM cutter on the rock sample after the initial crack is produced. Meanwhile, the reduction in peak strength index (PSI) and mean load index (MLI) values indicates that the penetration difficulty is significantly reduced. Hence, this contributes to the improvement of the boreability while the TBM is digging in highly abrasive hard rock.

Similar content being viewed by others

References

Alber M, Yaralı O, Dahl F, Bruland A, Käsling H, Michalakopoulos TN, Özarslan A (2013) ISRM suggested method for determining the abrasivity of rock by the CERCHAR abrasivity test. In: The ISRM suggested methods for rock characterization, testing and monitoring: 2007–2014. Springer, pp 101–106

Alehossein H, Detournay E, Huang H (2000) An analytical model for the indentation of rocks by blunt tools. Rock Mech Rock Eng 33(4):267–284

Balci C (2009) Correlation of rock cutting tests with field performance of a TBM in a highly fractured rock formation: a case study in Kozyatagi-Kadikoy metro tunnel, Turkey. Tunn Underg Space Technol 24(4):423–435

Balci C, Tumaç D (2012) Investigation into the effects of different rocks on rock cuttability by a V-type disc cutter. Tunn Underg Space Technol 30:183–193

Bilgin N, Copur H, Balci C (2016) Effect of high strength rocks on TBM performance. TBM excavation in difficult ground conditions: case studies from Turkey. Wiley-VCH Verlag GmbHCoKGaA, Weinheim 10(9783433607190)

Cheatham JB Jr (1958) An analytical study of rock penetration by a single bit tooth. Dissertation, University of Minnesota

Cheng JL, Jiang ZH, Han WF, Li ML, Wang YX (2020) Breakage mechanism of hard-rock penetration by TBM disc cutter after high pressure water jet precutting. Eng Fract Mech 240:107320

Cheng JL, Wang YX, Wang LG, Li YH, Hu B, Jiang ZH (2021) Penetration behaviour of TBM disc cutter assisted by vertical precutting free surfaces at various depths and confining pressures. Arch Civ Mech Eng 21(1):1–18

Cho JW, Jeon S, Jeong HY, Chang SH (2013) Evaluation of cutting efficiency during TBM disc cutter excavation within a Korean granitic rock using linear-cutting-machine testing and photogrammetric measurement. Tunn Underg Space Technol 35:37–54

Ciccu R, Grosso B (2010) Improvement of the excavation performance of PCD drag tools by water jet assistance. Rock Mech Rock Eng 43(4):465–474

Ciccu R, Grosso B (2014) Improvement of disc cutter performance by water jet assistance. Rock Mech Rock Eng 47(2):733–744

Deliormanlı AH (2012) Cerchar abrasivity index (CAI) and its relation to strength and abrasion test methods for marble stones. Constr Build Mater 30:16–21

Deng R, Liu JP, Kang MQ, Zhang WT (2022) Simulation and experimental research of laser scanning breaking granite. Optics Communications 502:127403

Geng Q, Wei ZY, He F, Meng H (2015) Comparison of the mechanical performance between two-stage and flat-face cutter head for the rock tunnel boring machine (TBM). J Mech Sci Technol 29(5):2047–2058

Gharahbagh EA, Rostami J, Talebi K (2014) Experimental study of the effect of conditioning on abrasive wear and torque requirement of full face tunneling machines. Tunn Underg Space Technol 41:127–136

Hoek E, Marinos P (2000) Predicting tunnel squeezing problems in weak heterogeneous rock masses. Tunn Tunn Int 32(11):45–51

Huang X, Liu QS, Shi K, Pan YC, Liu JP (2018a) Application and prospect of hard rock TBM for deep roadway construction in coal mines. Tunn Underg Space Technol 73:105–126

Huang JG, Wang HG, Ji GD, Zhao F, Ming RQ, Hao YL (2018b) The rock breaking mechanism of ultrasonic high frequency rotary-percussive drilling technology. Paper presented at the Petroleum Drilling Techniques: Issue 4, 2018

Huo JZ, Sun W, Chen J, Zhang X (2011) Disc cutters plane layout design of the full-face rock tunnel boring machine (TBM) based on different layout patterns. Comput Ind Eng 61(4):1209–1225

Jeong HY, Cho JW, Jeon S, Rostami J (2016) Performance assessment of hard rock TBM and rock boreability using punch penetration test. Rock Mech Rock Eng 49(4):1517–1532

Innaurato N, Oggeri C, Oreste PP, Vinai R (2007) Experimental and numerical studies on rock breaking with TBM tools under high stress confinement. Rock Mech Rock Eng 40(5):429–451

Jiang H, Zhang X, Liu S, Cai Z (2022) Research on the mechanism and performance of free-surface rock breakage by a disc cutter. Eng Fract Mech 264:108336

Karakurt I, Aydin G, Aydiner K (2014) An investigation on the kerf width in abrasive waterjet cutting of granitic rocks. Arab J Geosci 7(7):2923–2932

Lawn B, Wilshaw R (1975) Indentation fracture: principles and applications. J Mater Sci 10(6):1049–1081

Li GH, Wang WJ, Jing ZJ, Zuo LB, Wang FB, Wei Z (2018) Mechanism and numerical analysis of cutting rock and soil by TBM cutting tools. Tunn Underg Space Technol 81:428–437

Li W, Yan P, Lu A, Huang SL, Lu WB (2022) Effect of confining pressure on peak penetration force of the TBM disc cutter. Arab J Geosci 15(11):1–12

Liu H (2013) UCS and BTS tests of rock cores from northern Tasmania

Liu HY, Kou SQ, Lindqvist PA, Tang CA (2002) Numerical simulation of the rock fragmentation process induced by indenters. Int J Rock Mech Min Sci 39(4):491–505

Liu Q, Liu QS, Pan YC, Peng XX, Deng PH, Huang K (2018) Experimental study on rock indentation using infrared thermography and acoustic emission techniques. J Geophys Eng Fract Mech 15(5):1864–1877

Liu Q, Pan YC, Deng PH (2021) Mechanical and acoustic emission responses of rock fragmentation under disc cutter penetration. Adv Civ Eng. https://doi.org/10.1155/2021/8829046

Liu QS, Huang X, Gong QM, Du LJ, Pan YC, Liu JP (2016) Application and development of hard rock TBM and its prospect in China. Tunn Underg Space Technol 57:33–46

Liu QS, Liu Q, Liu XW, Sun L, Zhang XB, Ji J (2017) Experimental study on penetration failure of soft-hard interbedded rock mass under a wedge indenter. Rock Soil Mech 38(7):1849–1855 (in Chinese)

Liu SY, Liu ZH, Cui XX, Jiang HX (2014) Rock breaking of conical cutter with assistance of front and rear water jet. Tunn Underg Space Technol 42:78–86

Liu XS, Xu M, Qin PW (2019) Joints and confining stress influencing on rock fragmentation with double disc cutters in the mixed ground. Tunn Undergr Space Technol 83:461–474

Log S, Brox D, Anderson T (2017) The return of TBMs to Norway at Røssåga HEPP–TBM operation through extremely hard rock, unstable rock mass and other challenges. Paper presented at the World Tunnel Congress Bergen, Norway

Lu YY, Tang J, Ge ZL, Xia BW, Liu Y (2013) Hard rock drilling technique with abrasive water jet assistance. Int J Rock Mech Min Sci 60:47–56

Lu ZL, Wang XC, Teng HW, Guan XM, Song C, Fan G (2022) Rock-breaking laws of disc cutters with different height differences in hard rock strata. Adv Civ Eng 2022

Ma HS, Yin LJ, Ji HG (2011) Numerical study of the effect of confining stress on rock fragmentation by TBM cutters. Int J Rock Mech Min Sci 48(6):1021–1033

Maurer WC (1966) The state of rock mechanics knowledge in drilling. Dissertation, University of Minnesota

Oh TM, Cho GC (2014) Characterization of effective parameters in abrasive waterjet rock cutting. Rock Mech Rock Eng 47(2):745–756

Petrica M, Badisch E, Peinsitt T (2013) Abrasive wear mechanisms and their relation to rock properties. Wear 308(1–2):86–94

Rui FX, Zhao GF (2021) Experimental and numerical investigation of laser-induced rock damage and the implications for laser-assisted rock cutting. Int J Rock Mech Min Sci 139:104653

She L, Zhang SR, Wang C, Du M, Yang P (2022) A cutting mechanics model of constant cross-section type disc cutter and its application based on dense core theory. Int J Rock Mech Min Sci 150:105025

Teymen A (2020) The usability of Cerchar abrasivity index for the estimation of mechanical rock properties. Int J Rock Mech Min Sci 128:104258

Tóth Á, Gong QM, Zhao J (2013) Case studies of TBM tunneling performance in rock–soil interface mixed ground. Tunn Underg Space Technol 38:140–150

Ündül Ö (2016) Assessment of mineralogical and petrographic factors affecting petro-physical properties, strength and cracking processes of volcanic rocks. Eng Geol 210:10–22

Yagiz S (2008) Utilizing rock mass properties for predicting TBM performance in hard rock condition. Tunn Underg Space Technol 23(3):326–339

Yagiz S (2009) Assessment of brittleness using rock strength and density with punch penetration test. Tunn Underg Space Technol 24(1):66–74

Yaralı O, Yaşar E, Bacak G, Ranjith PG (2008) A study of rock abrasivity and tool wear in coal measures rocks. Int J Coal Geol 74(1):53–66

Yin LJ, Gong QM, Ma HS, Zhao J, Zhao XB (2014) Use of indentation tests to study the influence of confining stress on rock fragmentation by a TBM cutter. Int J Rock Mech Min Sci 72:261–276

Zhang JL, Li YC, Zhang YS (2020) Using a high-pressure water jet-assisted tunnel boring machine to break rock. Adv Mech Eng 12(10):1687814020962290

Zhang KZ, Yu HD, Liu ZP, Lai XM (2010) Dynamic characteristic analysis of TBM tunnelling in mixed-face conditions. Simul Model Pract Theory 18(7):1019–1031

Zhang SR, She L, Wang C, Wang YJ, Cao RL, Li YL, Cao KL (2021) Investigation on the relationship among the Cerchar abrasivity index, drilling parameters and physical and mechanical properties of the rock. Tunn Underg Space Technol 112:103907

Zhang XH, Lin LK, Xia YM, Tan Q, Zhu ZM, Mao QS, Zhou M (2018a) Experimental study on wear of TBM disc cutter rings with different kinds of hardness. Tunn Undergr Space Technol 82:346–357

Zhang XP, Ji PQ, Liu QS, Liu Q, Zhang Q, Peng ZH (2018b) Physical and numerical studies of rock fragmentation subject to wedge cutter indentation in the mixed ground. Tunn Undergr Space Technol 71:354–365

Zheng YL, He L (2021) TBM tunneling in extremely hard and abrasive rocks: problems, solutions and assisting methods. J Cent South Univ 28(2):454–4801

Zhou Y, Yin SY, Zhao DJ (2019) Effect of static loading on rock fragmentation efficiency under ultrasonic vibration. Geotech Geol Eng 37(4):3497–3505

Zhu Y, Wang XL (2020) The research of TBM cutterhead crack propagation rate model during full stage. Eng Fail Anal 118:104806

Funding

The research work is supported by the National Natural Science Foundation of China (Grant No. 42267022, U1934208, 42177140, 41807250), the Natural Science Foundation of Jiangxi Province (No.20212BAB204012, 20202ACB211002, 20212BBE53016, 20212BAB214009), and the State Key Laboratory of Performance Monitoring and Protecting of Rail Transit Infrastructure Foundation (No. HJGZ2021102).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare no competing interests.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Jiang, Y., Zeng, J., Xu, C. et al. Experimental study on TBM cutter penetration damage process of highly abrasive hard rock pre-cut by high-pressure water jet. Bull Eng Geol Environ 81, 511 (2022). https://doi.org/10.1007/s10064-022-03022-1

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s10064-022-03022-1