Abstract

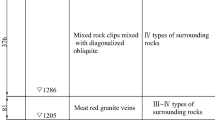

To overcome the problems existing in the application of the traditional stability control method of the surrounding rock of deep shafts, in this paper, a stability control method for the surrounding rock of deep shafts is presented based on the New Austrian Tunnelling Method (NATM) and the Norwegian Method of Tunnelling (NMT), and a support design method of deep shafts is also proposed. In addition, taking a deep shaft construction project as an example, the support design process of a deep shaft is presented: the engineering geology and in situ stress of the deep shaft are collected and processed to evaluate the rock mass quality with the Q-system, rock mass rating (RMR), and geological strength index (GSI). The strength and deformation parameters of the intact rock are obtained via laboratory tests, and the rock mass mechanical parameters are calculated using the generalized Hoek–Brown method. Then, a variety of support design methods based on rock mass classification systems are applied to determine the primary and permanent support, and the support time is obtained on the basis of a convergence-confinement analysis and engineering experience. A two-dimensional plane-strain model is constructed to analyze and evaluate the safety of the proposed support system, incorporating the major geological discontinuities and non-hydrostatic in situ stress state prior to excavation.

Similar content being viewed by others

References

Aksoy CO (2008) Review of rock mass rating classification: historical developments, applications, and restrictions. J Min Sci 44(1):51–63. https://doi.org/10.1007/s10913-008-0005-2

Alejano LR, Rodriguez-Dono A, Alonso E, Fdez-Manin G (2009) Ground reaction curves for tunnels excavated in different quality rock masses showing several types of post-failure behaviour. Tunn Undergr Sp Tech 24(6):689–705. https://doi.org/10.1016/j.tust.2009.07.004

Barton N, Grimstad E, Aas G et al (1992) Norwegian method of tunnelling. World Tunn 5(6)

Barton N, Grimstad E (1994) Rock mass conditions dictate the choice between NMT and NATM. Tunnels & Tunnelling 26(10):39–42

Barton N (1998) NMT support concepts for tunnels in weak rocks. In: Tunnels and Metropolises: Proceedings of the World Tunnel Congress. 25–30 April, 1998, Sao Paulo, Brazil, 273–279

Brown ET (1981) Putting the NATM into perspective. Tunn Tunn Int 13(10):13–17

Bieniawski ZT (1984) Rock mechanics design in mining and tunnelling. United States

Brown ET, Bray JW, Ladanyi B, Hoek E (1983) Ground response curves for rock tunnels. J Geotech Eng-Asce 109(1):15–39. https://doi.org/10.1061/(ASCE)0733-9410(1983)109:1(15)

Bieniawski ZT (1989a) Engineering rock mass classifications: a complete manual for engineers and geologists in mining, civil, and petroleum engineering. John Wiley & Sons, London, pp 91–93

Bieniawski ZT (1989b) Engineering rock mass classifications: a complete manual for engineers and geologists in mining, civil, and petroleum engineering. John Wiley & Sons, London, pp 51–60

Bieniawski ZT (1989c) Engineering rock mass classifications: a complete manual for engineers and geologists in mining, civil, and petroleum engineering. John Wiley & Sons, London, pp 94–95

Cai MF, Qiao L, Li CH (2000) Measuring results and regularity of in situ stress in Xincheng gold mine. Nonferrous Met 52(3):1–6. (in Chinese) https://doi.org/10.1520/STP48458S10.3969/j.issn.2095-1744.2000.03.001

Cai MF (2002) Rock mechanics and engineering. Science Press, Beijing (in Chinese)

Carranza-Torres C, Fairhurst C (2000) Application of the convergence-confinement method of tunnel design to rock masses that satisfy the Hoek-Brown failure criterion. Tunn Undergr Space Technol 15(2):187–213. https://doi.org/10.1016/S0886-7798(00)00046-8

Deere DU, Hendron AJ, Patton FD, Cording EJ (1967) Design of surface and near-surface construction in rock. In: Proceedings of the 8th US symposium on rock mechanics (USRMS), Minneapolis, Minnesota, 237–302

Deere DU, Deere DW (1988) The rock quality designation (RQD) index in practice. In: Proceeding of Symposium on Rock Classification for Engineering Purposes. 1987, Ohio, USA, 91–101. https://doi.org/10.1520/STP48458S

Duncan-Fama ME (1993) Numerical modeling of yield zones in weak rock. In: Analysis and design methods, Pergamon Press, London, pp: 49–75. https://doi.org/10.1016/B978-0-08-040615-2.50009-5

Fabich S, Bauer J, Rajczakowska M, Świtoń SP (2015) Design of the shaft lining and shaft stations for deep polymetallic ore deposits. Min Sci 22:127–146. https://doi.org/10.5277/msc152213

Gumusoglu MC, Bray JW, Watson JO (1987) Analysis of underground excavations incorporating the strain softening of rock masses. In: Proceedings of the 6th International Congress of the ISRM, 30 August –3 September, 1987, Montreal, Canada, pp 923–928. (in Germany)

Golser J (1979) Another view of the NATM. Tunn Tunn 11:41

Grimstad E, Barton N (1993) Updating the Q-system for NMT. In: Proceedings of the International Symposium on Sprayed Concrete-Modern use of wet mix sprayed concrete for underground support, Oslo, Norway

Hagenhofer F, Watts D (1990) NATH for tunnel with lingh overburden. Tunn Tunn 22(5):51–52

Holl GW, Fairon EG (1973) A review of some aspects of the shaft design. J South Afr Inst Min Metall 73(10):309–324

Hoek E, Brown ET (1997) Practical estimates of rock mass strength. Int J Rock Mech Min Sci 34(8):1165–1186. https://doi.org/10.1016/S1365-1609(97)80069-X

Hoek E, Carranza-Torres C, Corkum B (2002) Hoek-Brown failure criterion-2002 edition. In: Proceedings of NARMS-TAC, 7–10 July, 2002 Toronto, Japan 1(1):267–273

Hormazabal E, Soto C, Russo A, Carranza-Torres C (2012) Estimation of support requirement for large diameter ventilation shaft at Chuquicamata underground mine in Chile. In: Qian QH, Zhou YX (eds) Harmonising Rock Engineering and the Environment. CRC Press, Florida, pp 586–587

John M (1980) Investigation and design for the Arlberg expressway tunnel. Tunn Tunn 12(4):46–51

Jia XR (2010) Rock mechanics and strata control. China University of Mining & Technology Press, Jiangsu (in Chinese)

Karakuş M, Fowell RJ (2004) An insight into the new Austrian tunnelling method (NATM). In: The VIIth Regional Rock Mechanics Symposium, 21–22 October, 2004, Sivas, Turkey, pp 14

Kendorski FS, Hambley DF (1992) Other applications of geomechanics. In: Hartman HL (ed) SME Mining Engineering Handbook. Society for Mining, Metallurgy, and Exploration, United States, pp 972–988

Li J, Cheng LK, Li CJ et al (2015) Technical code for engineering of ground anchorages and shotcrete support. China Planning Press, Beijing (in Chinese)

Li CC (2017) Principles of rockbolting design. J Rock Mech Geotech 9(3):396–414. https://doi.org/10.1016/j.jrmge.2017.04.002

Li XP, Wang B, Zhou GL (2012) Research on distribution rule of geostress in deep stratum in chinese mainland. Chin J Rock Mech Eng 31:2875-2880. https://doi.org/10.3969/j.issn.1000-6915.2012.z1.036

Lee Y-K, Pietruszczak S (2008) A new numerical procedure for elasto-plastic analysis of a circular opening excavated in a strain-softening rock mass. Tunn Undergr Space Technol 23:588–599

Marinos P, Hoek E (2000) GSI: a geologically friendly tool for rock mass strength estimation. In: Proceedings of ISRM international symposium. 19–24 November, 2000, Melbourne, Australia, ISRM-IS-2000–035

McCreath DR (1980) Analysis of formation pressures on tunnel and shaft linings. M.S. Thesis, University of Alberta

Meng Q, Han L, Sun J, Min F, Feng W, Zhou X (2015) Experimental study on the bolt-cable combined supporting technology for the extraction roadways in weakly cemented strata. Int J Min Sci Techno 25(1):113–119. https://doi.org/10.1016/j.ijmst.2014.11.010

Merritt AH (1972) Geologic prediction for underground excavations. N Am Rapid Excav Tunn Conf Proc 1:115–132

Obert L, Duvall WI, Merrill RH (1959) Design of underground openings in competent rock. Government Printing Office, Washington D.C., pp 6–7

Oztork H (2000) Prediction of broken zone radius and lining thickness around circular mine shafts. M.S. Thesis. Middle East Technical University of Turkey

Ozturk H, Unal E (2001) Estimation of lining thickness around circular shafts. In: Proceedings of 17th international mining congress and exhibition of Turkey-IMCET2001, Ankara, Turkey, pp 437–444.

Ozturk H, Guler E (2016) A methodology for lining design of circular mine shafts in different rock masses. Int J Min Sci Techno 26(5):761–768. https://doi.org/10.1016/j.ijmst.2016.05.049

Panet M (1993) Understanding deformations in tunnels. In: Hudson JA et al (eds) Comprehensive Rock Engineering, vol 1. Pergamon Press, London, pp 663–690

Panet M (1995) Le calcul des tunnels par la méthode convergence-confinement. Presses de l’Ecole Nationale des Ponts et Chaussées, Paris

Purwanto W, Shimada S et al (2014) Support design of underground cut and fill mine by using Hybrid Numerical empirical model. J Geo Geosci 3(2):1–8. https://doi.org/10.4172/2329-6755.1000148

Pariseau WG (2017) Design analysis in rock mechanics. CRC Press, United States

Rocscience Inc. (2013) Phase2 Tutorials (version 8.014). Rocscience Inc., Toronto, Ontario, Canada

Salencon J (1969) Contraction quasi-statique d’une cavite a symetrie spherique ou cylindrique dans un milieu elastoplastique. Annales Des Ponts Et Chaussées 4:231–236

Sheorey PR (1994) A theory for in situ stresses in isotropic and transversely isotropic rock. Int J Rock Mech Min Geomech Abstr 31(1):23–34. https://doi.org/10.1016/0148-9062(94)92312-4

Singh B, Goel RK (2011a) Engineering rock mass classification: tunneling, foundations, and landslides. Butterworth-Heinemann, USA, pp 106–107. https://doi.org/10.1016/C2010-0-64994-7

Singh B, Goel RK (2011b) Engineering rock mass classification: tunneling, foundations, and landslides. Butterworth-Heinemann, USA, pp 104–105. https://doi.org/10.1016/C2010-0-64994-7

Terzaghi K (1943) Theoretical soil mechanics. John Wiley & Sons, New York, pp 11–15

Talobre JA (1957) La Mécanique des Roches appliqude aux travaux publics. Dunod, Paris, pp 228–233

Unal E (1996) Modified rock mass classification: M-RMR system. In: Bieniawski ZT (ed) Milestones in rock engineering, the Bieniawski jubilee collection. A.A. Balkema, Rotterdam/Brookfield, Illinois, pp: 203–223.

Unrug KF (1992) Construction of development openings. SME mining engineering handbook 2. Englewood, Colorado, pp 1580–1643

Vydrová LE (2015) Comparison of tunnelling methods NATM and ADECO-RS. Stavební obzor - Civ Eng J 24(1):1–7. https://doi.org/10.14311/CEJ.2015.01.0003

Vergne J (2003) Hard rock miner’s handbook. McIntosh Engineering, Ontario, USA

Wang Y (1996) Ground response of circular tunnel in poorly consolidated rock. J Geotech Eng-Asce 122(9):703–708. https://doi.org/10.1061/(ASCE)0733-9410(1996)122:9(703)

Wang YM (2012) Modern mining handbook. Metallurgical Industry Press, Beijing (in Chinese)

Xiao RL (2015) Review on development of mine shaft construction technology. Coal Sci Techno 43(8):13–22. https://doi.org/10.13199/j.cnki.cst.2015.08.003 (in Chinese)

Zhao DA, Chen ZM, Cai XL, Li SY (2007) Analysis of distribution rule of geostress in China. Chin J Rock Mech Eng 26(6):1265–1271. https://doi.org/10.3321/j.issn:1000-6915.2007.06.024

Zhao XD (2018) Basic theory and development trends of ultra-deep shaft construction. Metal Mine 502(04):7–16 (in Chinese). https://doi.org/10.19614/j.cnki.jsks.201804001

Zheng YR (2012) The stability analysis and design theory of surrounding rock of underground engineering. China communication press, Beijing (in Chinese)

Funding

The funding support for this study was provided by the National Key Research and Development Program of China (2016YFC0600803, 2018YFC0604401, and 2018YFC0604604) and the Project of NSFC-Shandong Joint Fund (U1806208).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that permission has been obtained from Xincheng Gold Mine for the use of engineering and geological data, and no potential conflicts of interest with respect to the research, authorship, or publication of this article.

Rights and permissions

About this article

Cite this article

Zhao, X., Li, Y. Estimation of support requirement for a deep shaft at the Xincheng Gold Mine, China. Bull Eng Geol Environ 80, 6863–6876 (2021). https://doi.org/10.1007/s10064-021-02350-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10064-021-02350-y