Abstract

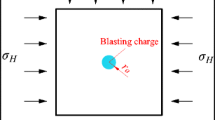

This study establishes a multiple degrees-of-freedom structural dynamics analytical model to analyse the influence mechanism of different factors on blasting tight bottom and shape of muckpile. The structural displacement response and distribution of internal forces in the bench rock mass are analysed based on several factors including blasting parameters, explosion load, initiation condition, and geological condition. In addition, the structural failure characteristics of the bench rock mass are studied based on a rock strength criterion. The results indicate that the explosive load strength determines the internal forces of the bench rock mass. The use of blasting parameters with large borehole spacing and small row spacing can increase the internal force and deformation of the bench rock and enhance the effect of the breaking and throwing of rock mass. In addition, the strengthening of the lithology of the bottom rocks or weakening of the lithology of the middle rocks can make destroying the bottom rock mass more difficult and increase the probability of blasting tight bottom formation. Adjusting the initiation point to below the weak-lithology segment of the bench can enhance the internal force and displacement of the bottom rock mass, to improve the blasting effect and avoid blasting tight bottom formation. Combined with the bench blasting field test of the Changjiu limestone mine, it verifies the results of the theoretical analysis of the bench blasting rock mass destruction based on structural dynamics. The results can be used as the theoretical basis and technical support for improving the bench blasting effect.

Similar content being viewed by others

References

Ash RL (1973) The influence of geological discontinuities on rock blasting. Dissertation, University of Minnesota.

Bhandari S (1996) Changes in fragmentation processes with blasting conditions. In: Mohanty (ed) Rock fragmentation by blasting: Fragblast 5. Balkema, Rotterdam, pp 301–309.

Bhandari S (1977) On the role of stress waves and quasi-static gas pressure in rock fragmentation by blasting. Gasdynamics of Explosions and Reactive Systems 365–383. https://doi.org/10.1016/B978-0-08-025442-5.50036-6

Chen X, Liao Z, Li DH (2011) Experimental study of effects of joint inclination angle and connectivity rate on strength and deformation properties of rock masses under uniaxial compression. Chin J Rock Mechan Eng 30(4):781–789 ((in Chinese))

Chen M, Liu T, Ye ZW, Lu WB, Yan P (2019) Calculation methods for peak pressure on borehole wall of contour blasting. Explosion and Shock Waves 39(06):103–112 ((in Chinese))

Dey A, Gupta RN, Ghose AK (1999) Blast evaluation using high speed video camera: a case study in Jharia coalfield. Journal of Mines, Metals and Fuels 47(1–2):31–35

Duan BF, Li JM, Zhang M (2010) BP neural network model on the forecast for blasting vibration parameters in the course of hole-by-hole detonation. Journal of Coal Science and Engineering 16(3):249–255. https://doi.org/10.1007/s12404-010-0306-3

Daehnke A, Rossmanith HP, Knasmillner RE (1996) Blast-induced dynamic fracture propagation. In: Mohanty (ed) Rock Fragment by blasting: Fragblast 5. Balkema, Rotterdam, pp 13–18.

Esen S, Onederra I, Bilgin HA (2003) Modelling the size of the crushed zone around a blasthole. Int J Rock Mech Min Sci 40(4):485–495. https://doi.org/10.1016/S1365-1609(03)00018-2

Fourney WL, Dally JW, Holloway DC (1978) Controlled blasting with ligamented charge holders. Int J Rock Mech Min Sci 15(3):121–129. https://doi.org/10.1016/0148-9062(78)90006-2

Faramarzi F, Farsangi MAE, Mansouri H (2013) An RES-based model for risk assessment and prediction of backbreak in bench blasting. Rock Mech Rock Eng 46(4):877–887. https://doi.org/10.1007/s00603-012-0298-y

Haghighi R, Britton RR (1988) Modelling gas pressure effects on explosive rock breakage. Int J Min Geol Eng 6:73–79. https://doi.org/10.1007/BF00881028

He C, Yang J (2019) Experimental and numerical investigations of dynamic failure process in rock under blast loading. Tunn Undergr Space Technol 83:552–564. https://doi.org/10.1016/j.tust.2018.08.047

Hu Y, Yang Z, Huang S, Lu W, Zhao G (2020) A new safety control method of blasting excavation in high rock slope with joints. Rock Mech Rock Eng 53:3015–3029. https://doi.org/10.1007/s00603-020-02113-3

Isakov AL, Kokovkin VP (1979) Model investigations of stemming behavior and calculation of the pulse during firing of borehole charges. Sov Min Sci 15(4):331–339. https://doi.org/10.1007/BF02499530

Johansson D, Ouchterlony F (2013) Shock wave interactions in rock blasting: the use of short delays to improve fragmentation in model-scale. Rock Mech Rock Eng 46(1):1–18. https://doi.org/10.1007/s00603-012-0249-7

Jiang LC, Zeng JJ, Wang GW (2016) A discrete dynamic response model with multiple degrees of freedom for horizontal goaf group. Chin J Rock Mechan Eng 5(1):59–67 ((in Chinese))

Kutter HK, Fairhurst C (1971) On the fracture process in blasting. Int J Rock Mech Min Sci 8(3):181–188. https://doi.org/10.1016/0148-9062(71)90018-0

Li XB, Xu Q, Lok TS (2001) Response of rock mass interface to impulsive loads induces by blasting. Frontiers of Rock Mechanics and Sustainable Development in 21st Century. Balkema, Netherlands, pp 73–81.

Liu YC, Wang XG, Liu LS, Dou JL (2011) An energy method for calculate borehole pressure under decoupled charging. China Mining 18(6):104–107 ((in Chinese))

Liu BC (2014) Study on hole stemming theory of one-step deep hole raise blasting and its application. Dissertation, Central south of university. (in Chinese)

Lu WB, Leng ZD, Chen M, Yan P, Hu YG (2016) A modified model to calculate the size of the crushed zone around a blast-hole. J South Afr Inst Min Metall 116(5):413–422. https://dx.doi.org/10.17159/2411-9717/2016/v116n5a7

Mandal SK, Singh MM, Dasgupta S (2008) Theoretical concept to understand plan and design smooth blasting pattern. Journal of Geotechnical and Geoenvironmental Engineering 26(4):399–416. https://doi.org/10.1007/s10706-008-9177-4

Ma L, Pai X, Zhang J, Xiao S, Zhang L, Tu Y (2020) Blast-casting mechanism and parameter optimisation of a benched deep-hole in an opencast coal mine. Shock Vibration 139:64–83. https://doi.org/10.1155/2020/1396483

Chinese National Standard (2014) GB/T50218-2014 standard for engineering classification of rock mass. China Planning Press, Beijing

Ning Y, Yang J, Ma G, Chen P (2011) Modelling rock blasting considering explosion gas penetration using discontinuous deformation analysis. Rock Mech Rock Eng 44(4):483–490. https://doi.org/10.1007/s00603-010-0132-3

Nielsen AH (2009) On the use of Rayleigh damping for seismic analysis. Proceedings of the Institution of Civil Engineers: Engineering and Computational Mechanics 162(4):215–220. https://doi.org/10.1680/eacm.2009.162.4.215

Sun Q, Ren JM, He SW. (1996) Experimental study on blasting bottom crushing of cantilever thin plate of bench rock. Nonferrous Metals (Mining) (04):29–32+47. (in Chinese)

Singh P, Roy M, Sinha A, Singh B, Singh VK (2012) Causes of toe formation at dragline bench and its remedial measures. In: Singh PK (ed) Rock Fragmentation by Blasting: Fragblast 10. CRC Press, London, pp 187–192

Tzu C, Hsu T (1989) T-shaped reinforced concrete members under biaxial bending and axial compression. Structure Journal 86(4):460–468

Trivedi R, Singh TN, Gupta N (2015) Prediction of blast-induced flyrock in opencast mines using ANN and ANFIS. Journal of Geotechnical and Geological Engineering 33(4):875–891. https://doi.org/10.1007/s10706-015-9869-5

Tileylioglu S, Stewart JP, Nigbor RL (2011) Dynamic stiffness and damping of a shallow foundation from forced vibration of a field test structure. Journal of Geotechnical and Geological Engineering 137(4):344–353. https://doi.org/10.1061/(ASCE)GT.1943-5606.0000430

Wang MY, Qian QH (1995) Attenuation law of explosive wave propagation in cracks. Chinese Journal of Geotechnical Engineering 17(2):42–46 ((in Chinese))

Yang XL, Wang MS (2001) Mechanism of rock crack growth under detonation gas loading. Explosion and Shock Waves 21(2):111–116 ((in Chinese))

Yang SL, Xu WY (2003) A simple method to estimate the effective elastic moduli of cracked rock. Journal of Hohai University (natural Sciences) 04:399–402 ((in Chinese))

Yilmaz O, Unlu T (2013) Three-dimensional numerical rock dam-age analysis under blasting load. Tunn Undergr Space Technol 38:266–278. https://doi.org/10.1016/j.tust.2013.07.007

Zhang ZX (2016) Rock fracture and blasting: theory and applications. Butterworth-Heinemann, Oxford

Zhu ZM (2009) Numerical prediction of crater blasting and bench blasting. Int J Rock Mech Min Sci 46(6):1088–1096. https://doi.org/10.1016/j.ijrmms.2009.05.009

Zhou J, Li XB, Mitre HS, Shiming W, Wei W (2013) Identification of large-scale goaf instability in underground mine using particle swarm and support vector machine. Int J Min Sci Technol 23:701–707. https://doi.org/10.1016/j.ijmst.2013.08.014

Acknowledgements

The authors wish to express their thanks to the National Natural Science Foundation of China.

Funding

This work is supported by the National Natural Science Foundation of China (Grant No. 51979205, No. 51779193).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Chen, M., Wei, D., Yi, C. et al. Failure mechanism of rock mass in bench blasting based on structural dynamics. Bull Eng Geol Environ 80, 6841–6861 (2021). https://doi.org/10.1007/s10064-021-02324-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10064-021-02324-0